Shrink your carbon footprint: Add renewable energy to cut carbon emissions and power costs

We are in the midst of one of the greatest energy transitions of our lifetime. And it has every industry asking itself: What can we do to promote sustainability and reduce our overall carbon emissions?

Buildings are being electrified and retrofitted with energy saving solutions. The transportation sector is embracing electric vehicles and alternative fuels to reduce emissions on our roadways. And power producers are taking steps to reduce the carbon intensity of the energy they provide to the electrical grid.

The same is true for the mining industry. Right now, mine operators around the world are searching for ways to truly become net zero carbon emitters and reduce their reliance on traditional power sources. This can be a tall order as mines require a significant amount of power to operate. But it is a challenge we must overcome if we hope to reach our sustainability goals by 2050.

Some people may be wondering why we can’t just shut down these mines and cut the associated emissions. But we can’t. Why? Because the precious minerals and metals that we’ll need to get us through the energy transition are still in the ground. They must be mined to produce the green technologies of the future.

Look no further than electric vehicle production as the world moves away from fossil fuels and combustible engines. Compared to a conventional car, building an electric car uses approximately six times the amount of minerals. And whereas conventional cars require mostly copper and manganese, electric vehicles require copper, manganese, nickel, lithium, cobalt, and more. But we also need most of these mined materials for renewable energy production, too. From solar panels to offshore wind turbines, our capacity to produce green energy relies on our ability to mine these materials. It couldn’t be clearer: If we hope to move towards a green and electric future, we’ll need the minerals and metals to do it.

So, we are facing two realities. We must reduce global greenhouse gas (GHG) emissions. And we must mine for the necessary materials to do that. These two realities must co-exist. So, the question remains: How can we reduce the carbon footprint of the mining industry and become net zero emitters?

One of the simplest solutions is by offsetting energy needs from fossil fuel power producers with renewable energy sources.

Brief rundown of scopes of emissions

When a mine operator is considering ways to reduce GHG emissions, they must first understand the three kinds –

or scopes – of emissions. The US Environmental Protection Agency (EPA) measures an organization’s overall carbon footprint as follows:

> Scope 1: Direct emissions that come from an organization itself and anything it owns or controls, such as facilities or vehicles.

> Scope 2: Indirect emissions that result from a company’s energy needs, such as those associated with the purchase of electricity, steam, heat, or cooling.

> Scope 3: Indirect emissions that result from a company’s upstream and downstream processes, such as the transportation, processing, and use of its end products.

There isn’t much that mine operators can do about Scope 3 emissions. Once the material is purchased and shipped out, emissions are out of their control and usually in the hands of the downstream producers. But there are a lot of actions that mines can take to reduce their Scope 1 and Scope 2 emissions. Electrification and producing power with renewable energy sources can help solve both. Let’s look at some examples below.

Becoming a power producer

Depending on the mine’s location, mine operators either purchase power from local energy providers or they will generate their own power. Becoming a power producer or supplementing purchased power with self-generated power sources is a good way to give mine operators more control of their Scope 2 emissions.

A combined heat and power plant (CHP) is a great self-generation solution for mine sites. Also known as cogeneration, a CHP plant generates electricity and thermal energy at the same time. This is a more sustainable solution for mine operators because the heat, which would otherwise be lost in the process, can be reused for other purposes. These include industrial processes, creating steam to generate electricity, heat buildings, or run steam chillers for cooling. Not only does a CHP generate a cleaner form of electricity, but it gives mine operators more control of their Scope 2 emissions.

If a mine operator is going to build a CHP on site, they’d be best off to develop their own microgrid and distributed energy resources as well. This creates what is essentially a mine’s own power grid, making the operator less reliant on power providers and offering more flexibility and higher efficiency rates. It also allows mines to bring together many forms of power generation and use them towards a common goal. For example, energy produced at the CHP plant can be supplemented with renewable energy sources like solar, wind or hydrogen. This gives operators even more leverage when they are working to reduce their Scope 1 emissions. Let’s look at some examples below.

A look at some renewable energy options

There are many different forms of renewable energy that can be useful on mine sites. And with the global focus on the energy transition, technology is improving, and the cost is coming down. Let’s review some of the renewable energy technology that mine companies should be considering:

> Solar power: Solar energy is an effective way of integrating renewable energy at mine sites. This is particularly true at mines with a large amount of unused land, and which have favorable solar radiation. This land can be used for cells of solar panels to help supplement the energy supply when the sun is shining.

> Wind power: Electricity generated from wind turbines is another great source of renewable energy at mines. Wind power also takes advantage of land that isn’t being used on mine sites to augment the energy supply when the wind is blowing and reduce the operator’s carbon emissions.

> Hydropower: Several mining clients already generate a substantial amount of their energy from hydropower. Further developments in microturbine technologies also provide opportunities to recover energy from gravity flow liquid systems within a mine to generate additional renewable energy.

> Biogas: While biogas is not a new concept, the adoption of it has grown significantly as improvements to technology and reductions in cost have occurred over time. Biogas can be used as fuel to power operations at a mine in more sustainable way – and it reduces the amount of physical waste at landfills in the process.

> Hydrogen: A rather new addition to our energy infrastructure is hydrogen. Hydrogen is the most abundant element in the universe, and it releases no GHG emissions upon combustion. Green hydrogen – or hydrogen produced from renewable energy sources – is a great way to augment a mine’s energy supply sustainably.

> Energy storage: Battery energy storage systems (BESS), pumped storage, and electro-mechanical flywheel energy storage all have potential uses of being incorporated into a mine’s microgrid. These technologies help to level demand by reducing peak loading and storing excess renewable energy generated.

It is important to understand that there is no silver bullet solution here. What worked for one mine might not work at another. If your mine is in a location that gets a lot of sunshine, then solar is part of your answer. If not, you’ll likely turn to wind power generation or hydrogen. If you have access to hydropower, of course use that. As you can likely tell, each mine will have its own conditions to navigate – there is no cookie cutter approach.

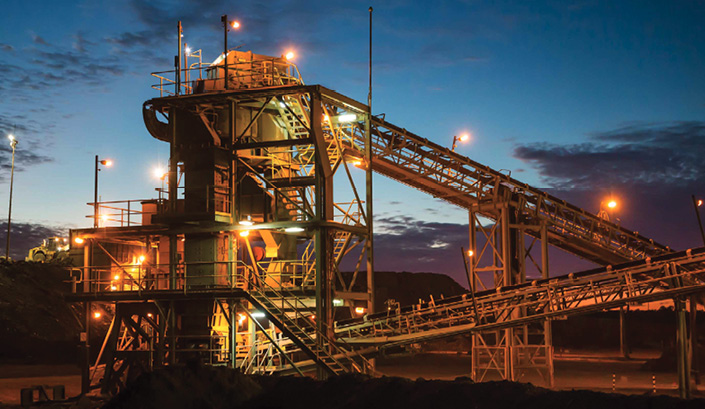

A (shining) example from down under

Now, let’s look at solar power in action.

Recently, Stantec has been working with TransAlta and BHP Nickel West (BHP) to develop a large-scale solar power project for a mine site down under. Located in the Goldfields of Western Australia, the Northern Goldfields solar project will help BHP power it’s Leinster and Mount Keith operations with two solar farms and a BESS.

The project will reduce the amount of power directed to the mines that is currently supplied by diesel and gas. This will help BHP reduce Scope 2 emissions at its Mount Keith and Leinster operations by 12%, resulting in an estimated reduction of 54,000 tonnes of carbon dioxide (CO2) emissions each year.

There are a few different components to this project. The first is a 27.4-MW solar farm at Mount Keith. The next is a 10.7-MW solar farm at Leinster, as well as a storage system that can hold up to 10.1 MW of energy (5.4 MW/h). The project also includes the interconnecting transmission infrastructure, all of which will be integrated into TransAlta’s 169-MW Southern Cross Energy North remote network.

This renewable energy project is the first solar photovoltaic build in Australia for TransAlta. It is also the first large-scale onsite solar farm and battery that BHP has commissioned and supports BHP’s emissions reduction targets. All while delivering lower-carbon, sustainable nickel to its customers.

Continuing to dig for sustainable solutions

The Northern Goldfields solar project will be successful for a couple key reasons. Of course, the fact that it will cut 540,000 tonnes of carbon emissions over the first 10 years of operation and save BHP on fuel costs is a significant achievement. But even better, the project can be used as a great example for other efforts to follow suit. Even for TransAlta and BHP, who hadn’t done anything like this before and can now look back at this project with a sense of certainty that these kinds of projects can be replicated at other sites. But more, now other mine operators who may have been skeptical of these kinds of projects can understand the great benefits that they can bring.

The mining industry needs to be looking at projects like this if they truly hope to reach net zero by 2050. As I said earlier, we must mine, but we must also mine in the most sustainable way.

Wayne Peel (wayne.peel@stantec.com) is general manager energy and resources at Stantec, Australia.

Comments