A Pioneering Partnership: Sandvik BEVs Powering Foran Mining’s Vision for Sustainable Mining at McIlvenna Bay

In an era where the mining industry is increasingly focused on sustainability and reducing its environmental impact, Foran Mining Corp.’s partnership with Sandvik Mining and Rock Solutions stands out as a groundbreaking endeavor. This collaboration, centered on the McIlvenna Bay copper project in Saskatchewan, Canada, represents the next step in carbon-neutral mining, driven by the deployment of one of the world’s largest fleets of battery-electric vehicles (BEVs) in an underground mining operation.

The McIlvenna Bay Project: A Vision for Sustainable Mining

The McIlvenna Bay project is Foran’s flagship operation, located in east-central Saskatchewan. Designed as an underground mine, it aims to produce approximately 4,900 tonnes of ore per day, primarily focusing on critical minerals such as copper, zinc, gold, and silver. These minerals are essential for the transition to a low-carbon future, playing a vital role in the production of electrical grids, solar panels, wind turbines, and batteries.

Foran’s vision of sustainable and responsible mining is reflected in its pursuit of carbon-neutral copper production at McIlvenna Bay. This approach is expected to prioritize minimizing environmental impact while maximizing social and economic benefits. A key strategy in realizing this vision is the early and comprehensive adoption of battery-electric vehicles, ensuring that every step aligns with Foran’s commitment to a cleaner, more sustainable future.

Going All-In on Battery-Electric Vehicles

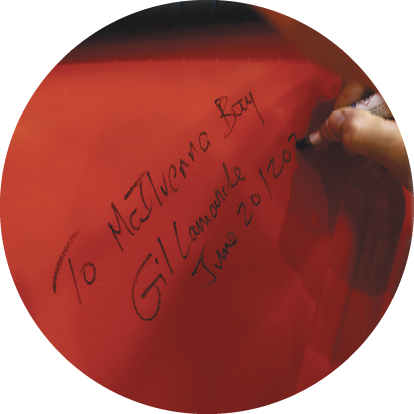

Foran’s decision to commit to a BEV fleet from the start, rather than adopting a more gradual approach, reflects the company’s confidence in the technology and its alignment with their sustainability goals. According to Gilbert Lamarche, Chief Operating Officer of Foran, the decision was driven by the maturity of BEV technology and the company’s commitment to responsible mining.

“It’s really aligned with Foran’s vision and mission, within our want to be responsible and sustainable miners. The team felt comfortable as to where the technology was. It’s not an R&D project. It’s being used,” Lamarche stated in a recent interview. This confidence was further bolstered by Foran’s previous experience with BEV technology during Lamarche’s tenure at Vale, where he witnessed the potential of electric vehicles in underground mining environments.

The McIlvenna Bay project’s startup fleet

will include 20 battery-electric vehicles from Sandvik, comprising seven LH518iB loaders, six TH550B trucks, four DD422iE jumbos, two DL422iE longhole drills, and one DS412iE mechanical bolter. This fleet is expected to not only reduce the project’s carbon footprint but also enhance operational efficiency and safety. The delivery of these vehicles began in late 2023, with full deployment expected by 2025.

The Role of Sandvik: A Leader in Mining Electrification

Sandvik Mining and Rock Solutions has emerged as a global leader in the development and deployment of battery-electric mining equipment. Their partnership with Foran is a testament to Sandvik’s commitment to driving sustainable mining practices through innovation. Peter Corcoran, VP of Sales Area Canada for Sandvik Mining and Rock Solutions, emphasized the significance of this partnership.

“This milestone agreement is the product of a year of partnership between Foran and Sandvik, underscoring our mutual commitment to electrification as the driving force behind the future of sustainable mining,” said Corcoran. He highlighted the enormous potential of BEVs to reduce a mining operation’s carbon footprint, noting that Canada is at the forefront of mining electrification and is setting a blueprint for other major mining regions to follow.

One of the key technologies that influenced Foran’s decision to partner with Sandvik is the AutoSwap and AutoConnect battery system. These innovations allow for rapid battery changes, minimizing downtime and maximizing productivity. Lamarche praised the system for its efficiency, noting that it is a waste of productivity, time and money when a vehicle is idle while charging the battery. The seamless operation of AutoSwap technology is expected to be a significant factor in achieving the operational goals of the McIlvenna Bay project.

Save Ventilation Costs and the Environment

While the initial capital investment in BEVs is higher compared to traditional diesel-powered equipment, Foran’s decision was driven by a comprehensive analysis of long-term costs and benefits. During the 2020 pre-feasibility study, Foran determined that the use of BEVs would result in better financial outcomes when considering the savings from reduced ventilation capital and operating costs. In underground mining, ventilation typically accounts for 60-70% of total mine power costs, and BEVs significantly reduce the need for extensive ventilation systems.

Moreover, the environmental benefits of BEVs are substantial. Foran estimates that the use of BEVs at McIlvenna Bay will eliminate approximately 350,000 liters of diesel consumption annually, equivalent to around 1,000 tonnes of CO2 emissions. Over the projected 20-year life of the mine, this reduction in emissions will have a profound impact, contributing to the global effort to combat climate change.

Foran’s commitment to sustainability extends beyond operational efficiencies. The company views its investment in BEVs as a strategic move that aligns with its broader brand values and resonates with environmentally conscious investors. “You look at overall, your company brand, your company name and the thirst for shareholders to be joining and investing in a company that is doing the right thing for the environment,” Lamarche explained.

A Collaborative Effort for a Sustainable Future

The partnership between Foran and Sandvik is characterized by a deep sense of co-operation and shared purpose. Both companies are heavily invested in the success of the McIlvenna Bay project, with daily communications and joint problem-solving efforts ensuring that the project remains on track to meet its ambitious goals. Lamarche described the relationship with Sandvik as “collaborative,” emphasizing the importance of trust and co-operation in navigating the challenges of deploying a full BEV fleet in an underground mine.

As the mining industry faces increasing pressure to reduce its environmental impact, the collaboration between Foran and Sandvik serves as a powerful example of what can be achieved through innovation, vision, and partnership. By pioneering the use of BEVs at McIlvenna Bay, these companies are not only advancing their own sustainability goals but also setting a precedent for the industry as a whole.

Mining the Benefits of Sustainability

The McIlvenna Bay project is more than just a mining operation; it is a potential blueprint for sustainable mining practices. Through their partnership with Sandvik, Foran is demonstrating that sustainability and profitability can go hand in hand. As the world moves towards a low-carbon future, the lessons learned from this project can benefit the direction of mining operations globally. The success of this partnership could inspire others in the industry to follow suit, accelerating the transition to more sustainable practices and ultimately contributing to the global effort to combat climate change.

Comments