Safety and efficiency do not need to be a compromise

Conveyors are among the fastest and potentially dangerous cargo transport systems for bulk handling operation. Even though their safety and performance are critical to the mine’s success, the impact of their contribution to overall efficiency is often unrecognized by management and workers alike. The operational basics of conveyor belt systems are too often a mystery to those employees who have little understanding about the hardware installed and the performance required from the components.

The knowledge gap is understandable. The attention of personnel at a bulk handling operation is centered on logistical and scheduling concerns. The “care and feeding” of belt conveyors — i.e., the adjustment, maintenance, and troubleshooting — make an enormous difference in safety and performance but are typically outside of operator’s expertise. It is not that they do not care about conveyors, but the ongoing maintenance and service of these systems is often usurped or deprioritized for other issues.

Low-bid process and life cycle cost

Although the policy is not explicitly stated by companies, the low-bid process is usually an implied rule that is baked into a company’s culture. It encourages bidders to follow a belt conveyor design methodology that is based on getting the “maximum load” on the conveyor belt and the “minimum compliance” with regulations, using the “lowest price” materials, components, and manufacturing processes available.

Maximizing the volume of cargo and minimizing the price of the system usually means choosing the narrowest feasible belt, operating at the highest speed possible. This leaves little margin for error and in many cases results in chute plugging, excessive spillage, and reduced equipment life.

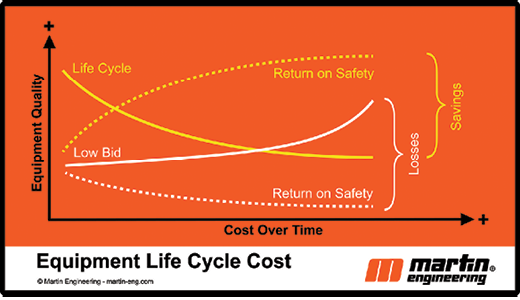

When companies buy on price, the benefits are often short-lived, and costs increase over time, eventually resulting in losses. In contrast, when purchases are made based on the lowest long-term cost (life-cycle cost), benefits usually continue to accrue, and costs are lower, resulting in net savings over time.

Conveyor system design hierarchy

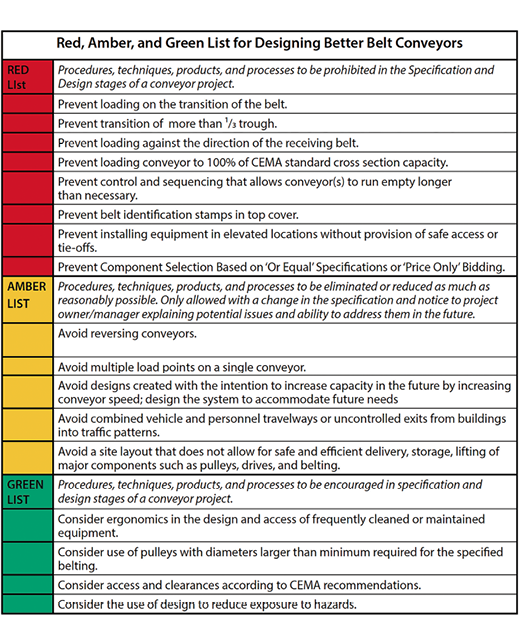

To safely maximize production, designers and engineers are urged to approach the project with a specific set of priorities. Rather than meeting minimum compliance standards, the conveyor system should exceed all code, safety, and regulatory requirements using global best practices. By designing the system to minimize risk and the escape and accumulation of fugitive material, the workplace is made safer, and the equipment is easier to maintain.

Life cycle costing should play into all component decisions. Be aware of specifications on project components that state “Specific Manufacturer Name or Equal.” Vaguely written “or Equal” specifications are there for competitive reasons and allow contractors to purchase on price without adequate consideration for construction or performance. Rather, buying on “Life Cycle Cost” or “Engineer-Approved or Equal” and anticipating the future use of problem-solving components in the basic configuration of the conveyor provides improved safety and access, without increasing the structural steel requirements or significantly increasing the overall price. It also raises the possibility for easier system upgrades in the future. The ability to accommodate future increases in capacity can also be included in the original design, expanding options, and reducing future modification costs.

Designing conveyor upgrades for safety

There is continuous pressure from managers to increase production to match demand. However, standards continue to tighten as government regulators retain their strong focus on worker safety, driving the need for equipment designs that are not only safe, but also optimized for safety (designed for safety). Personnel are the single most valuable resource of any industrial operation. That is why conveyor system designers are incorporating greater functionality into designs that will improve safety.

To reduce hazards in the workplace, operators employ a variety of methods from requiring the use of personal protective equipment (PPE) to installing the latest and safest equipment designs. When examining the safety of a system, improving efficiency, and reducing risk can be achieved by utilizing a hierarchy of control methods for alleviating hazards. The consensus among safety professionals is that the most effective way to mitigate risks is to “eliminate the hazard by design”. This usually requires a greater initial capital investment than short-term fixes but yields more cost-effective and durable results.

Examples of “eliminate by design” are longer, taller, and tightly sealed loading chutes to control dust and spillage or heavy-duty primary and secondary cleaners to minimize carryback. By using hazard identification and risk-assessment methods early in the design process, engineers can create the safest, most efficient system for the space, budget, and application. These designs alleviate several workplace hazards, while minimizing cleanup and maintenance, reducing unscheduled downtime, and extending the life of the belt and the system itself.

Experienced engineers often recommend that operators retain an outside firm to examine system requirements and design new equipment around historical issues and specific needs of the application. An outside eye can observe potential hazards that can be overlooked by workers who experience them daily.

Before the drafting phase, designers should establish the goals of reducing injuries and exposure to hazards (dust, spillage, etc.) to increase conveyor uptime and productivity, and seek more effective approaches to ongoing operating and maintenance challenges. Designs should be forward-thinking, exceed compliance standards, and enhance operators’ ability to incorporate future upgrades cost-effectively and easily by taking a modular approach.

Combining safety and productivity

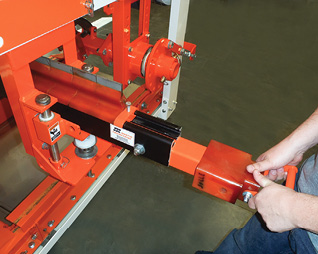

To meet the demands for greater safety and improved production, some manufacturers have introduced equipment designs that are not only engineered for safer operation and servicing, but also for reduced maintenance time. One example is a new family of heavy-duty conveyor belt cleaners, designed so the blade cartridge can be pulled away from the belt for safe access and replaced by a single worker.

The same slide-out technology has been applied to impact cradle designs. The systems are engineered so operators can work on the equipment safely, without breaking the plane of motion. External servicing reduces confined space entry and eliminates reach-in maintenance, while facilitating faster replacement. The result is greater safety and efficiency, with less downtime.

Another example of a revolutionary new belt cleaner design that can reduce the need for bulky urethane blades altogether is a belt-cleaning system that has received awards for its innovative design and safety benefits. The patented design delivers extended service life, low belt wear, significantly reduced maintenance, and improved safety, delivering lower cost of ownership. Unlike conventional belt cleaners that are mounted at an angle to the belt, this unique cleaner is installed diagonally across the discharge pulley, forming a three-dimensional curve beneath the discharge area that conforms to the pulley’s shape. The novel approach has been so effective that in many operations, previously crucial secondary belt cleaners have become unnecessary, saving further on belt-cleaning costs and service time.

Conclusion

Engineering safer conveyors is a long-term strategy. Although design absorbs less than 10% of the total budget of a project, engineering, procurement, construction, and management (EPCM) services can be as much as 15% of the installed cost of a major project. Additional upfront engineering and applying a life cycle-cost methodology to the selection and purchase of conveyor components proves beneficial. By encouraging the use of the “hierarchy of controls” at the planning stage, along with the “design hierarchy” at the design stage, the installation of an “evolved basic conveyor” can be achieved. The system will meet the demands of modern production and safety regulations, with a longer operational life, fewer stoppages, and a lower cost of operation.

R. Todd Swinderman is president emeritus of Martin Engineering.

Comments