Responsible mining: Teck’s water strategy

Interview with Chris Kennedy, director of water, Teck Resources

Chris Kennedy is the director of water at Teck Resources. Kennedy is focused on water governance and water strategy, with a particular emphasis on identifying new water management approaches and technologies to enhance operational sustainability at Teck’s operations, development projects, and legacy sites. He has over 20 years of experience working in academia, mining finance, consulting, and another senior mining company. He is a registered professional geologist in B.C. and Ontario and graduated with a BSc in geology and zoology from the University of Toronto (2000) and a PhD in microbial geochemistry from the University of Toronto (2003).

Building on the success of our first Reimagine Mining symposium, this year’s event connected delegates with industry leaders on the forefront of mining industry. The role of new technologies in water management was the main topic of the 2022 event. This article summarizes an interview with Chris Kennedy (CK), director of water, Teck Resources. He is a specialist who will shed light on how to implement new technology solutions in mine wastewater management.

TE: As a conversation starter, can you describe what a “director of water” does at a mining company?

CK: Water is an essential resource for people, communities, and the environment. It is also a critical input to the mining process. Water is one of Teck’s eight strategic themes along with health and safety, climate change, people, responsible production, tailings management, communities and Indigenous Peoples, and biodiversity and reclamation. Our sustainability strategy has long-term strategic priorities and shorter-term sustainability goals.

This role is an appreciation of the mining industry for the importance of water management to the business success and sustainability. There are three things that are key to my role at Teck (three pillars): The first one is leading our governance approach to ensure de-risking water usage operations and environmental risk is minimized and managed. Through this governance program, we try to bring in industry best practices, ensuring all the sites are operating as best as we can or figuring out ways to help them get there. The second one is driving our strategic priorities. There are two key strategic priorities, and part of my role is ensuring we have the right resources to help drive those forward and understand how they work in the business. The third pillar in my job is using my experience in the mining industry as a subject matter expert for all Teck’s new projects, ongoing projects, and closed sites.

TE: Can you please talk about Teck’s water strategic priorities and goals?

CK: There are two main strategies: The first one is utilizing either seawater or low-cost, low-quality water, especially in water stress regions, such as the copper mines in Chile where we made the decision to use desalinated water by treating seawater. The ocean is about 150 km from the mine site, and about 4,400 metres above the ocean. So, we are pumping it quite far and quite high which is not easy, but we have a massive copper resource. The second one is implementing innovative water treatment or water management. The other thing we are trying to do is distill it down before we send it to our process mill.

There are many water treatment technologies out there, and they continue to evolve, so we have an inhouse team that evaluates and develops new technologies, such as Teck’s saturated rock fills (SRF) technology.

This is effectively going beyond needing a treatment facility to building our mine waste facilities differently through a collaboration with the International Network for Acid Prevention.

Can we get away from water treatment by 2040? This won’t happen overnight, but we want to move away from having to build dedicated facilities, so it is an exciting time with a lot of work to do to keep mining sustainably.

Teck’s strategic priorities:

> Transition to seawater or low-quality water sources for all operations in water-scarce regions by 2040.

> Implement innovative water management and water treatment solutions to protect water quality downstream of all our operation.

Short term goals:

> By 2025, design all development projects in water-scarce regions with a seawater or low-quality water source.

> By 2025, implement new source control or mine design strategies and water treatment systems to further advance efforts to manage water quality at our operations.

TE: Can you touch on Teck’s water policy and its commitment to protect water and the life it sustains?

CK: It would be great if we could mine without water, but we cannot. We need it in the middle of the process, and it is a human right to have access to water. Everything that lives in our environment needs clean water. Our water policy is a public document, signed by our CEO and chair of the board and states a consistent and strong transparent water governance. We want to manage our water at our operations efficiently and effectively, then to collaborate to achieve responsible and sustainable water use both internally and with our stakeholders, such as governments, local communities, and First Nations, not just inward looking.

TE: Can you please talk about the technology behind the use of saturated rock fills (SRFs) to treat mine-affected water and the benefits of SRF over other forms of water treatment?

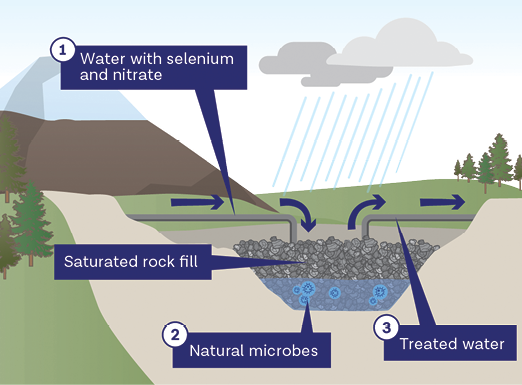

CK: Teck has collaborated with several research partners to develop and test the effectiveness of SRF technology to treat mine-influenced water. SRFs use naturally occurring biological processes in mining areas that have been backfilled with rock and saturated with water to remove selenium and nitrate. In this case, imagine the situation where we had the coal and the rock around the coal, and we were left with an open pit. We are in a water surplus region, so the pit does fill back up with water. It is like an ice cream scoop where the water is halfway down the ice cream, so you do not see a lake of water because of the rocks on top of it. And natural microbes live within this water saturated with rock, that is the SRF part. Water for treatment is injected into the SRF, and natural bacteria convert dissolved forms of selenium into a solid form which remains securely stored in the SRF, and nitrate to inert nitrogen gas which is safely released. Finally, treated water is pumped out of the SRF and discharged.

The use of saturated rock fills to treat mine-affected water is a leading-edge sustainable technology. SRF is extremely effective at removing selenium and nitrate from mine affected water and improving water quality. SRF technology is quicker to build and less complex to operate. Other benefits of SRF over other forms of water treatment include lower capital and operating costs, the capacity to treat larger volumes of water, use of less energy, and a smaller environmental footprint.

This is one of those fantastic things in my career where many things about the bacteria that live there was part of my PhD work. When water leaves these facilities, 95% of the selenium and nitrate is gone. SRF is an amazing technology that did not exist five years ago, and it is going to be a key technology in wastewater treatment moving forward in Elk Valley.

TE: 2021 was a big year for water treatment in Elk Valley; how did Teck manage the expansion of Elkview SRF facility to double its capacity?

CK: One of the great things about SRFs is that they are in a huge mine pit. The reactions are happening quite close to where we inject the water and give them a carbon source, and we have a lot more capacity than we think we do. At Elkview, it started out at 10,000 m3 per day. Over the next few years, from 2018 to 2021, we tried to figure out how the water was moving in the pit, so hydrogeology aspects, microbial characterization aspects, geochemistry aspects, water management, and engineering. A dedicated, passionate team staged and focused on the science, R&D, and engineering studies, and moved it up to 20,000 m3 per day. And then again, through monitoring where the water is moving to understand risks and opportunities of what we could do, we think there is room for more. There is the basics of engineering and science study, there is also the passion of the people in the Elk Valley, and honestly, one of the most incredible teams I have ever worked with, and I worked for a couple of different places. I think it comes down to the fact that for people who live there, this is their livelihood, their backyard, their families recreating these waters. So, I think it is people’s passion and engineering and science where we all came together to make that happen and are helping it move forward as well.

TE: Finally, are there any other plans that Teck is working on?

CK: We have a water quality plan that is moving forward and was developed with the government and First Nation groups to understand what the water quality is we need to get to and how do we get there.

Our first water treatment facility is successfully treating 7,500 m3 of water per day at our Line Creek operations, and we are seeing reductions in selenium and nitrate concentrations downstream.

The second water treatment facility, the Elkview SRF, has been achieving near complete removal of selenium and nitrate from up to 10,000 m3 of water per day since 2018. As I mentioned before, in 2020, this SRF was expanded and is now treating up to 20,000 m3 of water per day. Our third water treatment facility, the Fording River South water treatment facility, is now operating with capacity to treat up to 20,000 m3 of water per day. Finally, our fourth water treatment facility, the Fording River North SRF, is currently commissioning with expected initial capacity to treat up to 9,500 m3 of water per day. Construction is underway to expand this facility to 30,000 m3 of water per day by the end of 2022.

Teck’s water treatment facilities are achieving approximately 95% removal of selenium and nitrate from treated water. We expect further significant reductions of selenium and nitrate as additional facilities come online.

Following the start-up of the Fording River South water treatment facility, Teck now has up to 47,500 m3 per day of water treatment capacity in the Elk Valley. After completion of the FRO-N SRF water treatment facility by the end of this year, Teck will have capacity to treat up to 77,500 m3 of water per day, a four-fold increase from its treatment capacity in 2020. With the additional capacity, we expect to achieve one of the primary objectives of the Elk Valley water quality plan: stabilizing and reducing the selenium trend in the valley.

Visit our website for a full recording of the interview, including answers to several technical questions from the audience.

Comments