Maximizing lithium production efficiency

Interview with Zachary Sadow, CEO of KMX Technologies

KMX Technologies, LLC is a company dedicated to solving critical environmental and energy challenges of the 21st century. Through its proprietary membrane distillation technology, the company sustainably sources critical minerals necessary for next generation supply chains and infrastructure, is advancing wastewater treatment, and is accelerating energy storage with its direct lithium recovery enhancement processes. KMX delivers zero-waste solutions using its proprietary technology spanning water, lithium, and critical minerals.

Lithium is an essential component of a sustainable future as it is a necessary element in EV batteries and grid storage solutions for renewable energy. KMX recently partnered with CanmetMINING of Natural Resources Canada (NRCan) to maximize sustainable and economical lithium production in Canada. KMX will be using their membrane distillation technology in conjunction with CanmetMINING’s expertise in water treatment to optimize the concentration of lithium while maximizing water recovery of the highest quality.

This partnership will enhance lithium recovery across North America, making a sustainable future more possible. The partnership is timely, as it coincides with the Inflation Reduction Act recently passed by U.S. President Joe Biden. As part of that bill, American consumers receive tax credits for purchasing EVs with batteries whose materials were sourced in North America. This increased demand for North American lithium means that sustainable and economical production is essential to avoid supply chain issues and therefore maximize the positive impact on Canada’s economy.

Recently, I interviewed Zachary Sadow (ZS), CEO of KMX Technologies. Sadow explained how KMX has changed how critical minerals and lithium are secured, while providing next generation water treatment opportunities.

CMJ: Can you talk to us about the history of KMX Technologies? How long have you been with KMX Technologies, and how did KMX start providing zero-waste solutions to mining companies?

ZS: KMX was founded in 2020 as part of an IP and asset acquisition, building on over 15 years of deep technology development and vacuum membrane distillation leadership. We rolled the IP and assets into the newly formed KMX Technologies, began making critical enhancements to the technology, and soon after started focusing on lithium concentration as our core end-market.

The technology has gone through multiple generations of enhancements and successful demonstrations across various fields. Since founding the new company in 2020, we have done a few things that built on the prior 15 years of technology development. First, we have enhanced the technology significantly by the introduction of our Generation III membranes. The performance and durability of the Generation III membranes represent a significant improvement over the previous generation. Second, we have improved our supply chain and our ability to scale up by partnering with companies such as Sumitomo Electric.

The third significant thing is the emergence of lithium as a core focus since the founding of the company in 2020. With the global energy transition, lithium prices have taken off, and KMX has a unique application as a lithium concentrator.

CMJ: What makes the new membrane distillation technology of KMX unique, and are you collaborating with other companies to develop this technology?

ZS: What we do is unique and specific, but we are extraordinarily collaborative in our approach to the market. We have a great manufacturing and strategic partner of core elements, Sumitomo Electric Industries Ltd. In 2021, KMX and Sumitomo entered an MOU to commercialize KMX’s membrane distillation technology. Recently, we signed a global oil and gas technology licensing agreement with Tetra Technologies, which is a large oil service company that has an emerging focus on new energy. We also collaborate with our mining industry clients, which are really looking to develop various mining projects with our newest generation of technology.

CMJ: Can you briefly explain the separation technology and how it works?

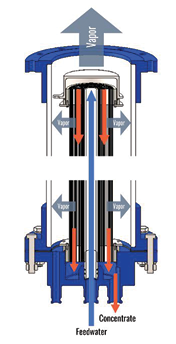

ZS: KMX is solving three of the biggest environmental challenges with its proprietary technology: water, lithium, and critical minerals. We have a powerful crosscutting technology that facilitates a separation of pure water, minerals, and other valuable constituents from brine and waste streams at low temperature and pressure. This technology has a broad set of applications across various industries and regions, specifically for industries that have a complicated waste stream but also need a high-quality water as an input, e.g., the mining industry. While the lithium, mining, and oil and gas industries represent obvious market opportunities for us, several other industries, such as chip manufacturing, industrial manufacturing, inland desalination, and pharmaceuticals are also particularly attractive for our technology.

The process starts by feedwater entering the module and then it flows up through center core. When feedwater reaches top of module, it is distributed and flows downward through the fibers to the concentrate outlet, and then it is recirculated in the same manner. The hydrophobic membrane acts as a barrier to the liquid and only vapor can pass through the membrane. Then, a vacuum is applied on the shell side (outside of the membrane). The combination of vacuum depth and heat creates phase transition from water to vapor on the membrane surface. Finally, water vapor passes through the membrane, is released from the modules, and it is condensed downstream.

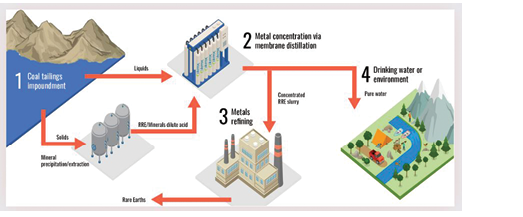

CMJ: How does the overall KMX’s critical minerals recovery process work?

ZS: Rare Earths and other critical minerals in waste present significant opportunity. Separation from tailings or waste ponds is estimated to represent 80% cost savings versus mining those critical minerals. For lithium production, our technology enables mining companies to maximize lithium concentration while also maximizing water recovery. The lithium market is our core focus currently, while Rare Earths represent a growth opportunity that we are not yet focused on.

There are three steps in recovering battery grade lithium from brine:

The first step is to extract the lithium, which is found in low concentrations alongside other salts and minerals like sodium chloride and magnesium, which need to be separated out. Today, that is done in evaporating ponds in South America; however, direct lithium extraction is an emerging technology which is an alternative to evaporating the water.

Once that step is done, lithium is still in very low concentrations, and it needs to be concentrated up to a point where it can be converted from its natural state, which is lithium chloride, to battery grade lithium, which is lithium hydroxide or lithium carbonate. That is what we do; we concentrate the lithium chloride. We do this while achieving maximum high quality water recovery. And finally, step three is refining the lithium chloride to battery-grade lithium (lithium hydroxide or lithium carbonate).

CMJ: So, KMX’s separation technology only comes into that process at the second step, is that correct?

ZS: Yes. Step one: extract. Step two: concentrate, which is what we do. Step three: refining. We are a complimentary technology to direct lithium extraction and to the refining processes. We are currently working with several mining companies that are using direct lithium extraction processes.

Importantly, a major criticism of the direct lithium extraction technology is that it utilizes a lot of water as part of the washing process. While it does not evaporate the water, like the evaporation ponds, it still needs a lot of fresh water. As part of our lithium concentration process, we recover water as part of the process. It is synergistic for a mining company to pair their direct extraction technology with our technology to maximize project economics, sustainability, and water recovery. We are trying to reach zero waste of water by recycling the water back into the process.

CREDIT: KMX TECHNOLOGIES

CMJ: KMX recently partnered with CanmetMINING; can you talk to us about this agreement and what you are hoping to achieve by this partnership?

ZS: We are hoping to maximize sustainable and economical lithium production in North America. KMX will be using our proprietary membrane distillation technology in conjunction with CanmetMINING’s expertise in water treatment to optimize the concentration of lithium while maximizing water recovery of the highest quality.

We are very excited to work with CanmetMINING of NRCan through a task-shared agreement, as part of the Federal Research and Development component of the Canadian government’s $47.7 million Critical Minerals Research, Development, and Demonstration Program announced under Budget 2021. We will be using the funding as CanmetMINING’s lithium concentration technology partner to optimize the three-step process in bringing lithium from its natural state to battery grade lithium.

Natural Resources Canada is looking for the best available technologies and processes to optimize that process in the most economical and sustainable manner. We are extraordinarily proud that they have chosen KMX’s technology for the lithium concentration part of the process.

CMJ: Do you think your technology will play an important role in reducing the cost of lithium production to help attract more investments in the North American battery manufacturing sector?

ZS: North America has significant lithium resources readily available to be extracted in a sustainable and economical manner. KMX’s work with the Canadian government will help ensure the coming North American lithium supply chain reshoring build-out is done with the highest environmental considerations. This partnership will highlight and optimize the steps that most efficiently, economically, and sustainably bring resources to the market for mining companies.

This will encourage more mining companies to develop lithium resources in North America and will drive down the cost of production. It will also enhance the environmental and ecological considerations and the whole ESG component of the mining process, which is such a focus for investors, industry, and governments.

CMJ: How does the future look like for KMX Technologies?

ZS: Building on our existing partnerships and execution for our existing customers is our focus for the immediate future. First, we have several exciting partnerships, and we are building on our recent licensing agreement with Tetra Technologies. We are excited about what is next in the global oil and gas markets, particularly as it relates to critical minerals that are found in mineral-rich produced water, which is a by-product of oil and gas production.

Second, we are also excited about our demonstrations and upcoming commercial development with our existing customers. We have two publicly announced LOIs with leading lithium mining companies. The first is with CleanTech Lithium, an exploration and development company, advancing the next generation of sustainable lithium projects in Chile. Based in the U.K., CleanTech Lithium is a leading lithium project developer that harnesses solar power and advanced technologies to sustainably source and produce commercial scale lithium, with an initial focus on Chile. We are honoured to be the lithium concentration partner of CleanTech Lithium, as they look to maximize lithium production efficiency and minimize its environmental footprint.

The second publicly announced letter of intent (LOI) that we have is with Cornish Lithium, which is a highly innovative private British mineral exploration company focused on the responsible extraction of lithium and other battery metals in the historically significant mining district of Cornwall, U.K.

Finally, I believe we have the leading membrane distillation laboratory in the world in Mississauga, Ont. KMX Technologies recently hosted a technology tour and opening ceremony of this new laboratory. The team was honoured to host government officials and management from Sumitomo Electric Industries Ltd., KMX’s strategic partner of core elements. Our lab is led by our distinguished technical team comprised of leaders in this technology. Dr. Matt Narrol, senior research scientist, demonstrated KMX’s lab scale vacuum membrane distillation unit at the event. Dr. Sean Ghayeni, head of technology, gave an overview of KMX’s proprietary Generation III membrane bundle, manufactured by Sumitomo Electric. Mostafa Nosraty, P. Eng. (KMX’s technical sales manager) also presented a commercial scale system rendering, currently planned for a leading lithium miner.

Comments