Less energy, more productivity with VOD at Éléonore mine

Ventilation is the greatest energy consuming system in most underground mines. Traditional operations, especially older ones, run their ventilation fans 24/7 to provide fresh air and to remove noxious gases and particulate matter.

It doesn’t have to be that way. Advances in ventilation on demand (VOD) offer real savings.

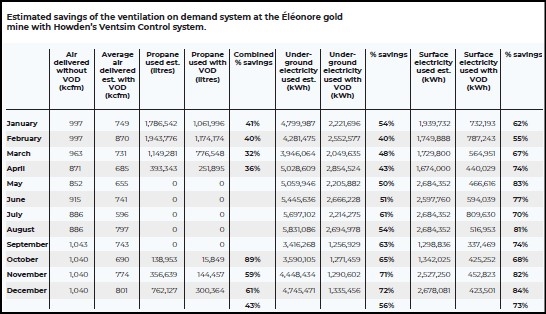

In the case of Newmont’s Éléonore gold mine, estimated energy savings thanks to VOD amounted to 43% on propane to heat underground air, 56% on electric power consumed by fans, and 73% on surface electric power demand.

The project is located in Eeyou Istchee or James Bay region of Quebec. The mine is 100%-owned by Newmont, and the 2022 guidance is 275,000 oz. of gold.

The Éléonore gold mine has a fresh air capacity of more than 425 m3/s. The principal ventilation system consists of two Howden Alphair 12300-AMF-6600 exhaust axial fans with a nominal power of 1,471 kWh each, configured in parallel. There is also an exploration shaft that has two Howden Alphair 11200-AMF-6600 main intake fans with a nominal power of 551.6 kWh, again configured in parallel. The mine also has over 140 auxiliary and booster fans operated in conjunction with seven dampers and air regulators, and a heating system fuelled by propane.

Newmont invited Howden to design and implement a ventilation control system that would optimize the supply of fresh air to underground workers while reducing energy consumption and operating costs – all of which translated into the reduction of greenhouse gases.

Howden set out to create an automated system covering all the ventilation equipment in the Éléonore mine, including the main fans, underground auxiliary fans and airflow regulators. Thirty ventilation monitoring stations (VMS) were installed to determine the quantity and quality of fresh air at various points underground. Each VMS includes one flow sensor and three gas sensors to detect carbon monoxide, nitrous oxides and propane. These VSM stations are an integral part of Howden’s Ventsim Control system.

The system communicates with all the hardware and instrumentation in the mine without the need of programming on the surface. The system automatically adjusts airflow according to real-time needs in the mine and allows easy point-and-click manual control as desired.

The Ventsim Control installation included a mine-wide tracking system to detect the presence of vehicles and personnel underground. Each of the 144 vehicles was fitted with a radio frequency identification (RFID) tag that indicates its position in the mine and whether the engine is operating. Everyone working underground was also given a unique RFID tag that connects to one of 254 zone-based access points. As mine conditions change, the system automatically recalculates and adjusts using the latest information.

The tracking data is transmitted from these access points to the control room on the surface through a hybrid fiber optic network. There is currently between 60% and 70% Wi-Fi coverage in the mine, with plans for 100% coverage during full production. The data from the RFID tags provides enhanced safety and management of the movement of vehicles and personnel, as well as ventilation on demand.

The data from the tracking system allows ventilation requirements for each zone to be calculated by the VOD logic software. This information is then used to automatically modify the speed of each of 140 underground auxiliary fans, to ensure that each zone of the mine receives enough fresh air.

The control system in the Éléonore mine can be easily expanded as the mine grows in size to maintain adequate, safe ventilation in every part of the workings as new areas and levels are opened up.

The installation of the Ventsim Control system, with its monitoring stations and automation of all ventilation equipment, means that the supply of fresh air to individual work zones is maintained with complete safety, ensuring all underground personnel have a comfortable working environment. At the same time, the waste associated with continual ventilation of the whole mine has been eliminated.

The results were verified by an energy audit caried out by Howden. The project could save almost 3.0 million litres of propane, 31 million kWh of underground electricity, and 19 million kWh of surface electricity.

The Éléonore mine benefited from reduced air waste because Ventsim Control calibrates in real-time to actual airflow needs where people and machinery are active. This increased production because blast gases were cleared quickly, reducing downtime up to three hours per production blast. Safety is improved because personnel do not control the fans manually. Contaminants gases are monitored and reduced to comply with regulations. The strategic deployment of variable frequency drives reduces power use by 50% to 60%. And the system is expandable.

Newmont chose Howden’s VOD system for its promised benefits in production, sustainability and safety – all of which were realized.

Comments