Juiced for the Job: Round up of BEVs powering the future of mining

This article sheds some light on how battery electric vehicles (BEVs) are transforming the mining industry by offering a cleaner, more efficient alternative to traditional diesel-powered equipment. These electric machines reduce greenhouse gas (GHG) emissions, improve underground air quality, and lower ventilation costs, making them particularly beneficial for underground mining operations. Here, we showcase how the recent advancements in BEVs are becoming more viable, offering longer running times, and faster charging solutions tailored to the demanding conditions of mining sites. Additionally, BEVs help mining companies meet sustainability goals and regulatory requirements while reducing operational costs associated with fuel and maintenance. As the mining industry shifts towards electrification, BEVs are playing a key role in shaping the future of mining.

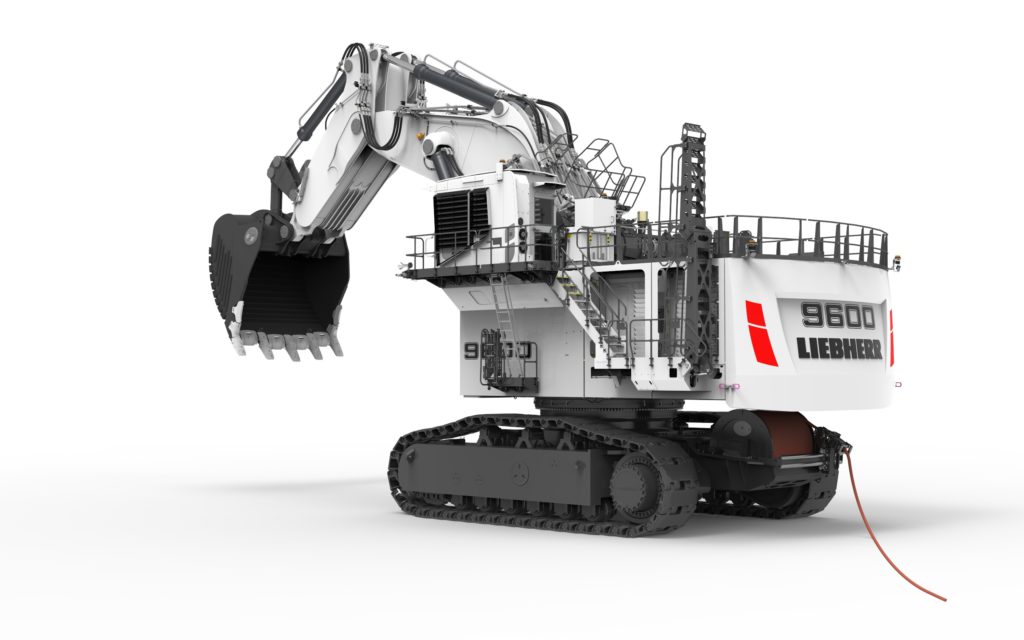

Say hello to the latest addition to Liebherr’s electric excavator portfolio: The R 9600 E!

This electric excavator has the same exceptional productivity as its diesel counterpart — the R 9600 — with the same class-leading bucket capacity but with some additional bonuses that only electric excavators can offer. Thanks to the R 9600 E’s electric motors,

the machine emits no GHG emissions on site, which significantly reduces customers’ carbon footprints. The electric motors also make for quieter operations, benefiting the operator in the cab and everyone else in and around the mine site! And, with the electric motor’s service life equal to that of the R 9600 E itself, maintenance costs are also decreased!

The MacLean fleet solution “BEVolution” continues

With the delivery of MacLean BEV fleets to Agnico Eagle’s Odyssey mine, Torex’s Media Luna project, and Glencore Onaping Depth project, MacLean will soon surpass the milestone of more than 100 battery electric units commissioned, with well over 500,000 hours of operating time accumulated since the launch of the company’s Fleet Electrification Program in 2015. Leveraging the lessons learned and benefiting from the depth of total cost of ownership (TCO) data that has been collected over the years, MacLean is there to help current and future customers achieve their own purpose-designed BEVolution.

Epiroc’s Scooptram ST18 SG arriving on Canadian soil

Epiroc’s Scooptram ST18 SG, the battery-powered loader built for demanding underground applications, is making its debut on Canadian soil in 2025 with two rigs set to arrive to customer sites in early June. The machine is ideal for larger mining operations, such as block caving or stoping and is automation-ready, adding another layer of worker safety to underground operations.

With one of the highest battery capacities on the market of 540 KwH nominal, the Scooptram ST18 SG can handle more than 1,300 tonnes on a single battery charge — keeping productivity at a high level throughout each shift.

Cat 793 XE Early Learner battery electric trucks begin testing and validation at global customer sites

The next generation of Caterpillar’s battery electric mining trucks are now at select customer sites for testing and validation. Caterpillar built and tested seven Cat 793 XE Early Learner battery electric trucks at its Tucson Proving Ground facility in Green Valley, Arizona. It is the second development phase of the company’s Early Learner program following the successful demonstration of the battery electric 793 prototype in 2022. Caterpillar will continue testing and validating some of the Early Learner trucks at its proving ground facility. The Early Learner program was launched to accelerate the development and validation of Cat battery electric large mining trucks with support from key mining customers and Cat dealers and will be critical to validate the enhanced design elements of the 793 XE.

Sandvik’s Toro LH518iB: Small footprint, advanced electric driveline

The Toro LH518iB is Sandvik’s next-generation battery-electric loader, designed to enhance productivity and safety in underground mining operations. With an 18-tonne payload capacity, it fits into 4.5 x 4.5-metre tunnels, offering high acceleration and fast ramp speeds owing to its advanced electric driveline. The loader features Sandvik’s patented AutoSwap and AutoConnect systems, enabling efficient, operator-assisted battery swaps without the need for large-scale equipment. Fully battery-powered, it produces zero underground exhaust emissions and significantly less heat than traditional diesel engines, supporting mining operations in reducing their CO2 emissions. Additionally, the Toro LH518iB is optimized for integration with Sandvik’s AutoMine automation system, further boosting operational efficiency. Learn more by visiting: https://www.rocktechnology.sandvik/

Aramine’s L440B LHDs

The first L440B LHDs are now reaching customers, marking a major milestone for Aramine’s battery-powered solutions. With a 4.6-tonne capacity, this groundbreaking loader eliminates the need for costly charging infrastructure, thanks to its integrated charger and ultra-fast battery swap system. Designed for extreme underground conditions, its LFP-based “energy module’ ensures safety, durability, and efficiency. Building on the success of the L140B, Aramine is expanding its battery-powered range, with a new mining truck coming soon. To meet the rising demand, a new factory is under construction. L440B order books are already full through 2026.

The KT300e delivers full vehicle performance

Kovatera’s purpose-built BEV, is designed from the ground up using advanced technology and proven components — never adapted or converted — ensuring superior durability and performance. Its heavy-duty 13,000-Ib frame, high-capacity braking resistor, and dedicated cooling system allow it to thrive in demanding underground conditions. The KT300e delivers full vehicle performance even at a high state of charge (SOC), with no speed limitations or runaways, maximizing battery efficiency and productivity. With zero emissions, reduced noise, and minimal heat, it outperforms in all categories while setting new standards for sustainable mining solutions. Explore more at www.kovatera.com.

Strength, sustainability, and safety: Powered by Rokion

Rokion is proud to introduce the R710, the latest in their line of battery powered utility equipment. Manufactured in Canada, the R710 is available with multiple custom front-end options, including a roof bolter and 10,000-Ib forklift configuration. If you are looking for a zero-emission alternative to your internal combustion equipment, then the R710 is the product for you.

Like all Rokion equipment, the R710 is powered by lithium iron-phosphate battery modules, offering exceptional safety and performance in the harsh underground environment. The R710’s robust, articulating frame and independent drive modules ensure superior handling and operation across uneven terrain.

Power your way with the adaptable 930E Power Agnostic Series from Komatsu

When it is time to transition to more sustainable power, Komatsu’s 930E Power Agnostic Series makes it simple. Its power-agnostic design offers the potential to integrate a wide range of current and future energy sources, giving you control over emissions and operational efficiency. Choose the power solution that fits your needs to help manage your carbon footprint while minimizing downtime and maximizing productivity. If you are ready to take the next step toward a more sustainable, cost-effective mining operation, learn how the 930E Power Agnostic Series can help.

Comments