How data from space can help miners’ supply chains on Earth

Over the past several decades, the infrastructure responsible for the movement of goods and people has become increasingly complex. Moreover, the interdependencies amongst and between critical assets, such as roads, railroads, ports, and airports have become much stronger. These factors, coupled with an increase in the intensity and frequency of extreme weather events resulting from a changing climate, have put our infrastructure systems at a considerable risk of disruption. Adverse weather events reduce the overall effectiveness and efficiency of all modes of transportation, which in turn leads to supply chain slowdowns and disruptions. In worst case scenarios, degradation in transportation operations can be accompanied by the loss of life, including those responsible for ensuring operations as well as those leveraging the service.

Mitigating the impact of weather, as it relates to the movement of goods and the safety of people, requires an integrated, seamless approach based on improved historical, current, and predicted weather data and information. Earth observations are at the core of these improvements, particularly the retrieval of data regarding the vertical structure of the atmosphere in data-sparse regions of the world. Such observations are essential in determining the initial state of the atmosphere, which can then be used to forecast the future state through tools such as numerical weather prediction (NWP) models.

Spire’s constellation of more than 100 satellites provides a proven platform for gathering Earth observations and has demonstrated that the time and cost of putting satellites into orbit can be significantly reduced. The capacity to place sensors in orbit in a fraction of the time and expense compared to conventional satellites opens the door to rapid innovation capable of facilitating enhanced understanding and prediction of extreme weather.

Consider the situation facing all the various kinds of ports which miners depend upon, whether on the seacoast, on the riverbank, or on a lake. The logistics systems on which miners depend are focused on optimizing port operations such that the right berth is open for the right ship at the right time. A ship that is delayed at port not only creates downstream supply chain disruption but increases costs while increasing pollution. A study published by Singapore’s Nanyang Technological University estimated that emissions from ships at the port of Los Angeles doubled between July 2020 and 2021 and increased by 123% in Singapore.

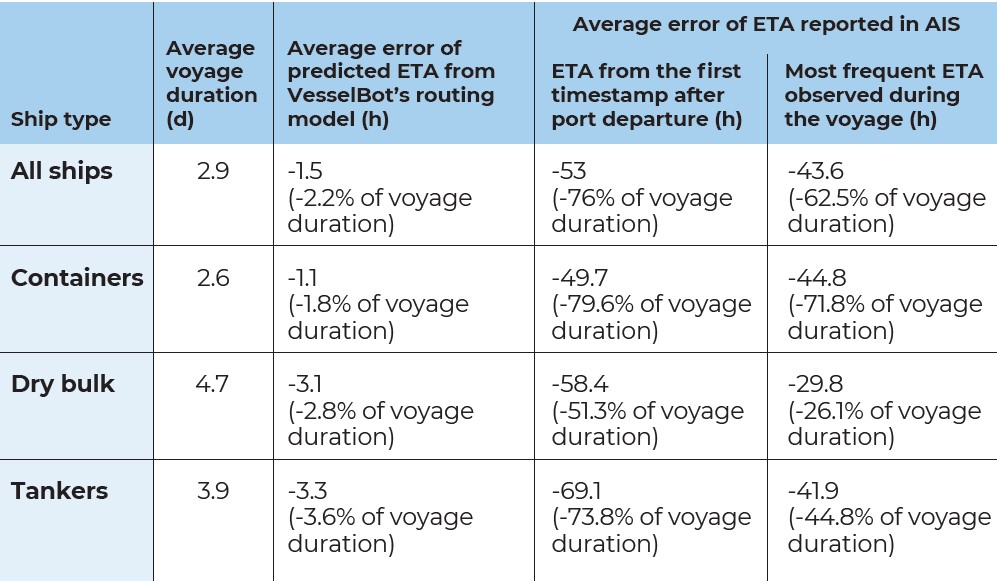

Historically, optimization has been difficult because the estimated time of arrival provided by ships is often off, up to 40 to 60 h (about 2.5 days). The EDS systems used to manage logistics can be a day late from when a ship arrives or departs.

Spire’s Maritime provides more accurate, objective, and data-driven approaches to predicting a ship’s arrival through real-time satellite tracking data and over 11 years of historical data to help train machine learning models.

This real-time vessel location along with port congestion data can also help operators make actionable decisions like slowing down the speed of the ship to save on both fuel costs and reduce carbon emissions near populated areas.

There is a clear link where actionable data insights can improve both supply chain performance and reduce harmful environmental impacts. The best way to solve your last-mile delivery problem is to start tracking and acting from the first mile.

The Port Optimized Forecast delivers data that includes dew point temperature, relative humidity, minimum and maximum temperature, precipitation probability, surface wind speed and direction, surface visibility, cloud coverage percentage, ice, and thunderstorm probability. This can help port authorities in managing vessel traffic during poor weather conditions such as fierce winds, swells, and currents.

Pushing forward on the use of such data by mining companies, Minehub Technologies is taking an initiative. It provides an open enterprise-grade platform for digital trade in the mining and metals supply chains and is using Spire’s satellite and terrestrial automatic identification system data, global vessel tracking data, and vessel characteristics to help power its commodities platform and optimize routing for bulk carrier vessels. The Spire Maritime solution is improving vessel data efficiency across the open ocean to the mining and metals supply chains.

The pressures of the pandemic and inflation have resulted in supply chains being strained across the globe. According to John Lusk, senior VP and maritime GM of Spire, his company’s maritime data solutions “help address the disruption by providing route visibility, analyzing fleet and vessel characteristics, and monitoring commodity trends. “We are excited to work with MineHub and provide cutting edge data to their platform because both companies are aligned on the increasing need to create digital solutions that create visibility and improve accuracy across the supply chain.”

MineHub’s digital platform is modernizing how the mining and metals supply chain operates. It provides greater transparency and traceability via real-time visibility, automation, streamlined credit management, paperless transactions, and emissions tracking. Spire’s AIS data will enhance coverage and reduce latency of tracking bulk vessels on MineHub’s integrated supply chain platform. The use of data and analytics allows for quicker decision making and shorter processes, which could save MineHub customers time and money.

Comments