Goldcorp turns to Newtrax to tackle visibility underground at Éléonore

Underground at Goldcorp’s Éléonore gold mine in Quebec. CREDIT: GOLDCORP

In the spring of 2017, Goldcorp’s Éléonore mine was reCognized for its outstanding safety record in the 2016 cAlandar year with the John T. Ryan National Safety Trophy for Metal mines. The award recognizes the mine’s achievement of 2,592,938 hours worked with a Éléonore reportable injury rate of 0.15 – the best rate of any metal mine in Canada that year. The operation also earned regional mining safety awards in 2015 and 2014.

The awards were sponsored by MSA Canada, a global leader in the development, manufacture and supply of safety products, and the John T. Ryan National Safety Trophy Committee.

Despite the high accomplishment, management of the Éléonore mine set out to do even better in 2017 in regards to safety. In fact, the safety benchmarks established by the operations leadership were seen as aggressive and hard to achieve.

How do you take one of the safest mines in the world and make it even safer?

With the assistance of Éléonore’s technical service manager, Gertjan Bekkers, Goldcorp looked to Newtrax Proximity Detection Solutions for their underground workforce and mobile fleet.

“Because Éléonore was so set up for innovation, particularly because of the connectivity in the underground, there were a lot more opportunities to implement technology,” Bekkers says. “We wanted proximity detection because we know that the interaction between the large equipment underground and the humans is a significant risk factor for these operations.”

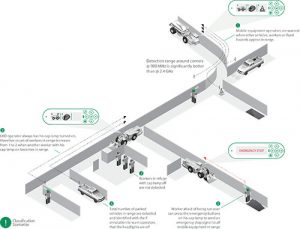

A major safety issue in underground mining is the threat of vehicular accidents – with other vehicles and with pedestrian miners. In recent years, it’s been reported that a large proportion of mining accidents are caused by a lack of visibility. Newtrax Proximity Detection solutions utilize sub-GHz RF technology to create a peer-to-peer network of vehicles and miners. Not only does it give out proximity warnings, the system can also be used to alert scoop operators that a truck is on its way even before it appears in its line of sight, enabling operators to prepare for the truck and improve mine production.

Through a thorough product search with a number of vendors, Goldcorp and the leadership of the Éléonore mine decided to partner with Newtrax Technologies for this project.

An illustration of how Newtrax Technologies’ personal safety devices work in an underground mining scenario. CREDIT: NEWTRAX TECHNOLOGIES

The project consisted of a mine-wide implementation of 660 new fully integrated Newtrax-enabled personal safety devices to be worn by the mine’s workers, which can reach up to 150 people underground at any given time.

The Newtrax-enabled personal safety devices are equipped with state-of-theart technology that enables:

- Location monitoring;

- Nuiance filtering;

- “Man-Down” alerts, which are sent to the surface if the worker is inert for more than 60 seconds; and

- Emergency evacuation notification.

In addition, proximity detection technology was also installed into the mine’s mobile equipment. With both systems installed, operators of large equipment are constantly notified when people and smaller equipment are in their proximity.

The Éléonore safety system works directly between the workers’ cap lamps and the equipment that is set up with the proximity detection system. The system works independently from the underground communication network, assuring its functionality in all areas of the mine. Goldcorp workers in the mine can be comfortable knowing that no matter where they are in the mine, there will be connectivity between them, their cap lamp and any machine in the surrounding area.

In 2017, Éléonore improved its safety performance and in doing so, raised the standard once again. Bekkers admits that a wide range of efforts went into achieving those numbers and establishing a strong safety culture amongst the workforce, but the Newtrax proximity detection system certainly played a part.

Continuing the innovation journey

The Newtrax Proximity Detection System implemented at Éléonore mine is only one example of Goldcorp’s innovation strategy that is disrupting all areas of its business.

Now their mines are built on digital platforms supported by fiber optic backbones and Wi-Fi. They have large volumes of data flowing in, and getting that data digitized and working for them is a big effort but significantly improves health and safety performance and can increase productivity.

When discussing innovation in the industry, Bekkers says “I think the industry is open to innovation. The industry wants it. It’s largely spurred by the fact that the world around us is changing and the world underground is not changing half as fast.”

For more information, go to www.Newtrax.com.

Comments