Conveyors: Guarding by location

Danger and compliance

The global leaders in conveyor safety are disputing the idea that putting conveyor equipment out of reach or inconveniently placed away from workers, known as “guarding by location”, is a valid form of safety. After decades of safe equipment design and comprehensive conveyor safety training in the bulk handling industry, Martin Engineering experts have witnessed where “guarding by location” has led to a lapse in workplace safety, resulting in injuries and, in some cases, fatalities.

Most people readily accept that conveyors and other machinery require safety guards when positioned near workers or walkways. Guarding by location is the assumption that when hazards, such as moving conveyor belts, are positioned beyond the normal reach of a worker, they do not require a guard. Yet, they can still present a serious hazard.

Worker risks from guarding by location

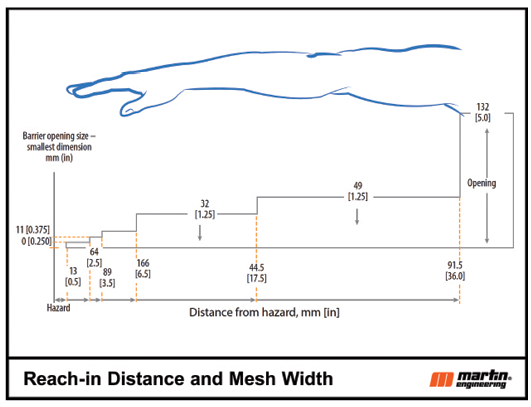

Some regulations define a general safe height for components based on the average height of workers. This means taller employees (1.82 m in height or more) can easily suffer an injury reaching up into a moving component that is 2.13 m above the ground. Working above machinery that is considered guarded by location exposes workers to increased severity of injury if they slip or fall to a lower level.

Most regulations do not account for the potential buildup of spillage underneath the conveyor or in walkways, which can easily change the distance between the working surface and a hazard. It is also fairly common practice to purposely collect a pile of material or fill a bin to gain access for service or inspection of an elevated component. Using tools and methods that extend a worker’s reach while the belt is running is a hazardous activity that can contribute to serious and/or fatal accidents.

Hazards from above

By not requiring a physical barrier, guarding by location creates what is considered by some to be an exception to the general requirements for the guarding of hazards in the workplace. Several hazardous locations are beyond the normal reach of staff when working or walking under or around elevated conveyors. These hazards are commonly found in or around nip points between the belt and return rollers or drive components such as pulley shafts, couplings, drive belts, gears, and chains. Additional hazards from falling components may be inadvertently ignored if considered guarded by location.

Guarding best practices

The logical solution to guarding by location is to simply install guards and baskets to protect workers from lateral and overhead hazards, while still offering safe and easy access. For maximum risk reduction, all nip points, shear points, and moving or rotating components should be guarded, regardless of location or access.

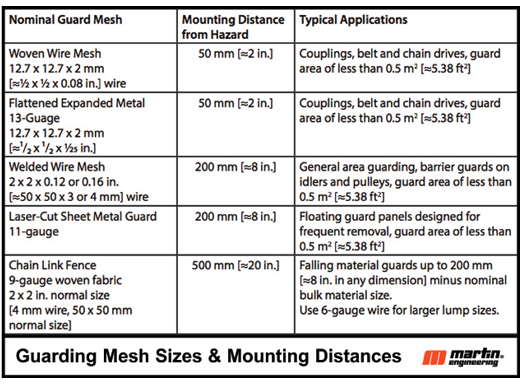

However, there is also no global standard for guard mesh sizes and mounting distance from the hazard. Most standards use a gauge to measure the distance which varies by mesh size. When a bulk material handling guard is placed relatively close to a hazard, it greatly reduces the ability to inspect components without removing the guard, thereby encouraging guard removal for routine inspections.

It would be far better (and safer) to standardize on a few mesh sizes and mounting distances, allowing maintenance workers to build guards to a short list of materials, using standard mounting distances and eliminating the use of the gauges. Below is the recommendation from Martin Engineering.

Put an end to the myth

Despite its nearly global acceptance as a concept in industrial safety, the practice of guarding by location remains a particular problem for overhead conveyor applications. It is time to accept that as far as conveyors are concerned, guarding by location is a myth. As such, it is a concept that should be abandoned to make conveyors, and those who work on and around the equipment, safer. CMJ

R. Todd Swinderman, P.E., is CEO emeritus, Martin Engineering, and Daniel Marshall is a process engineer at Martin Engineering.

Comments