BHP’s Jansen mine moves ahead

Shift to ‘future facing’ commodities has miner investing $7.5 billion in its first potash mine

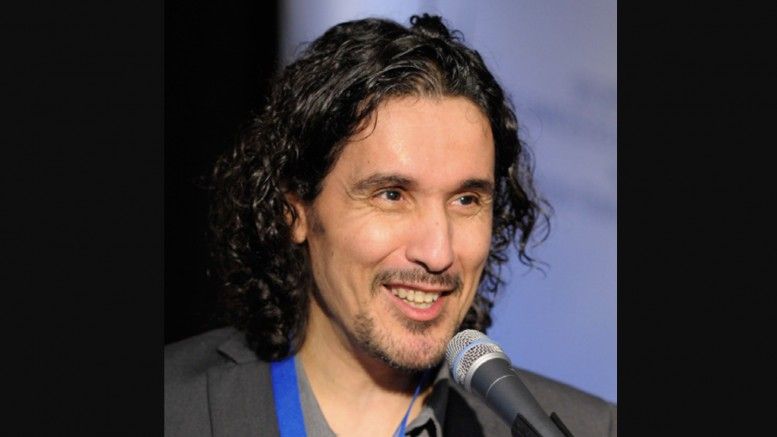

Simon Thomas, VP Projects for BHP believes in taking on challenges. Thomas successfully directed several large BHP iron ore projects in Australia and is now directing BHP’s $7.5-billion Jansen potash project in the Saskatchewan Potash basin. He moved from Perth, Australia, one of the world’s most liveable cities, to Saskatoon in January 2021 – the heart of Canadian winter. Thomas is also now embarking on a personal challenge: building a backyard skating rink and teaching his children to skate.

As the company’s first potash mine, Jansen will definitely be subject to challenges. But Thomas is confident the project will be completed on time and on budget.

“BHP has a strong track record of major project delivery,” he said in an interview in October. “We’ve recently completed four major projects worth about US$7 billion on time and on budget. Each of these projects, had a strong regional team focus, with global support through the Project Centre of Excellence and Global Project Management Leadership Team.”

In a long-awaited decision, the company announced it would go ahead with the Jansen Potash Stage 1 project in August 2021, budgeting $7.5 billion for the project, located 140 km east of Saskatoon. The project is expected to generate an internal rate of return (IRR) of 12-14% after taxes, with a payback of seven years. This does not take into account US$4.5 billion BHP has spent at Jansen since 2008. (It made its initial investment in 2006.) Earlier in 2021, BHP also wrote off US$1.3 billion due to an assessment of the project’s current market value.

The Jansen project is especially significant for BHP as its entry into a new “future facing” commodity – i.e., those that are needed for global economic growth and decarbonization. Potash joins BHP’s portfolio of copper, nickel, iron ore and metallurgical coal assets.

Project details

In 2011, BHP started sinking a 7.3-metre diameter production shaft to 975 metres depth and a service shaft to 1,005 metres at Jansen. This was done by DMC Mining using Herrenknecht’s Shaft Boring Roadheader (SBR) in frozen ground using a freeze plant. This was the first global shaft sinking using SBR instead of drilling and blasting. The shafts were completed in August 2018 with a primary liner. The composite hydro-static final liner that extends below the lowest water bearing foundation is expected to be completed shortly for both shafts. The ground around the shafts is frozen now. The brine temperature will be increased very gradually over months and even years to return the ground to normal temperatures while closely monitoring ground and water conditions.

The production shaft was designed for a 100-plus year mine life using very large equipment to attain the lowest production costs. The Stage 1 Jansen project will start production in 2027 and ramp up to full production of 4.4 million tonnes per year of potash in 2029. Canada is the world’s top producer of potash, accounting for 20.9 million tonnes of the total world production of 66.1 million tonnes in 2019, according to Statistics Canada. Jansen will be an important component of Canada’s potash supply. The project has probable reserves of 1 billion tonnes for a reserve life of 94 years. Additional measured and inferred resources are estimated at 6.5 billion tonnes.

The Hatch Bantel joint venture has been selected for engineering, procurement and construction management services. BHP has built relationships and entered into agreements with six primary First Nations in the vicinity of the Jansen project. It is also targeting 20% Indigenous representation in its operations workforce. BHP will be encouraging contractors to employ a diverse work force, including First Nations, as well as encouraging them to create opportunities for First Nations subcontractors. The expectation is that many of the 3,500 workers during peak construction will be coming from Saskatchewan primarily, as well as Canada and internationally. At full production, the site will host about 420 employees, with another 180 employees working out of the Saskatoon office and a new potash ship loading facility the company is building at Westshore Terminals, near Vancouver.

Mining process

Jansen Stage 1 mining will be done approximately 900 metres below surface at the top of the Prairie evaporate formation for a seam thickness of about 4 metres. A Sandvik MF460 full face borer miner will be used together with a Sandvik PO140 Extendable Belt System (EBS). This machine is considerably larger than other continuous mining machines in the Saskatchewan Potash basin. Four machines will each be capable of full production of about 2.7 million tonnes per year.

The MF460 will cut a width of 12 metres and a height up to 5 metres. One cut and a return cut will be up to 1.8 km in length, leaving a production pillar of 15 to 17 metres. The continuous mining machine has a cutting head that can vary in height and will have ground penetrating radar, so that waste or clay is not mined. The MF460 machine has been in development by Sandvik for over 10 years to de-risk this new approach. BHP and Sandvik have been conducting a full-scale underground trial in a salt mine in Germany over the last few years.

There will be an extensive network of conveyors to transport the ore from the room cut, to the panel conveyer, then to the mainline conveyor to the shaft. Initially, there will be 10 km of conveyors increasing to 100 km at full production. The ore will be hauled to surface and processed to have two types of potash: a standard-sized and granular-sized product. The tailings will be stored in the tailings management area for long-term closure estimated at about 50 years. The brine from processing will be disposed by brine wells to feed into underground aquifers of similar salinity.

Sustainability

Jansen has been designed with low operating costs and sustainability in mind. “Stage 1 will have approximately 50% less carbon emissions per tonne than the average in the basin and approximately 60% less fresh water consumed on the same basis,” says Thomas. “We expect more than 80% of the underground fleet’s energy will be supplied from battery or electric as Stage 1 comes online, with the plan to be fully electrified by 2031. There is also the potash path to net zero plan we’ve designed for Jansen, which focuses on eliminating power generation emissions at the source and mitigating the impact of natural gas consumption in the process area.”

The provincial and federal governments have been supportive of the project. The Saskatchewan government has updated sub-surface mineral regulations to accommodate large mines of the future together with ensuring the infrastructure and road safety is in place to support the Jansen project and worker safety. The federal government has provided research and development credits provided through the Ministry of Energy and Resources to encourage innovative investment.

The Jansen project is much more than a mine. It is a century vision that will bring long term jobs, growth, and many backyard skating rinks to an area of rural Saskatchewan.

Brian O’Hara, P Eng, MBA is a freelance writer based in Montreal.

Comments