ARTIFICIAL INTELLIGENCE IN MINING: From digging to data

How computer vision is shaping more productive and sustainable mining

Like diamonds, the mining industry is under immense pressure. The demand for the mining industry to continually boost safety and productivity is ever-growing, and one small slowdown can cost millions in revenue. To put this in perspective, only a 2% improvement in margin for the top mining players worldwide would drive over $19 billion in new mining profits.

Economic pressures aside, global warming is also challenging mines to stay sustainable while also maintaining profitability, a challenging feat to accomplish. According to ABB, 30% of mines are falling short of their decarbonization goals.

The demands for productivity and sustainability make keeping tabs on efficiency and safety of the utmost priority. But manual 24/7 monitoring of complex processes, large equipment, and dynamic environments is time-consuming, prone to error, and dangerous. Luckily, artificial intelligence (AI)-powered automation and computer vision can resolve these challenges and accelerate the progress of mines.

Computer vision is poised to transform the industry by providing real-time, visual insights into the entire mining lifecycle all the way from mineral processing to worker safety and site security. It elevates productivity, safety, and sustainability across the entire value chain to proactively address issues as they happen and offer optimization opportunities. Computer vision is undoubtedly the future of mining.

What is computer vision?

At a high level, computer vision is a subtype of AI that detects objects, people, and events in real-time, providing actionable data to improve operations. Leveraging neural networks and machine learning (ML), computer vision allows computers to analyze and understand the environment around them. The technology can be easily integrated with existing cameras and complements the sensor and machine vision technology already present in the mining market, such as temperature and pressure sensors, robotics, and advanced machinery.

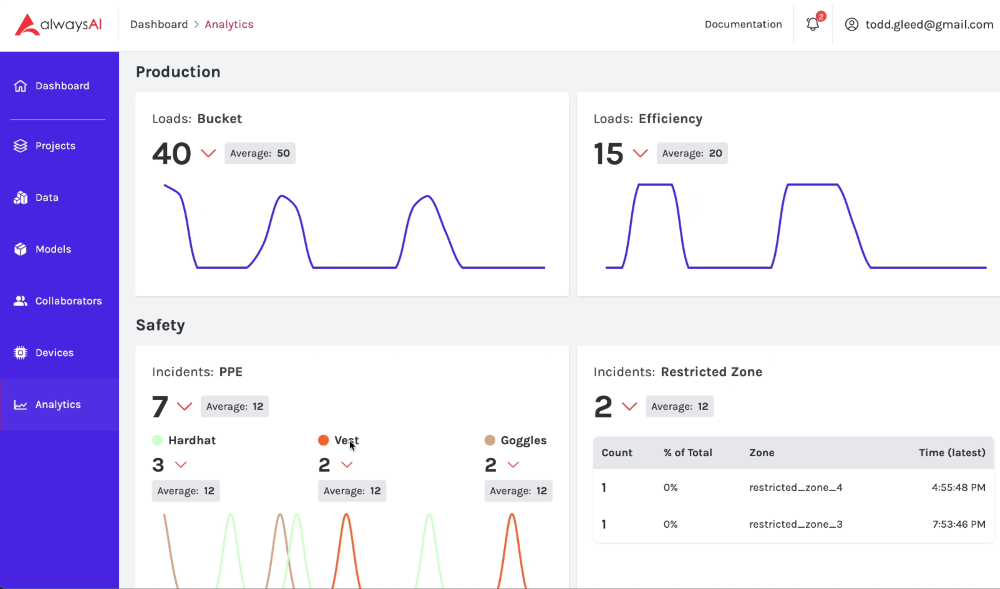

Because computer vision gathers real-time data that is more accurate than what manual monitoring can achieve, it is both resource and cost-effective over time. It helps operators address slowdowns, resolve safety violations, detect anomalies, and target inefficiencies immediately. Computer vision is the “practical” subset of AI that leaders across all industries are using to see transformative impact and ROI from.

Use cases for mining

Computer vision transforms logistics, health and safety, environmental monitoring, and site security of mines — boosting productivity and sustainability. It allows mines to keep up with the industry’s demands, while remaining profitable and scalable.

Because of the constant safety concerns, labour shortages, environmental pressures, and tight timelines faced by the mining industry, computer vision is truly revolutionary.

Drilling and excavating

An unplanned drill and excavator downtime on mine sites is detrimental for profitability and productivity. One small slow-down or machine breakdown can cost thousands in lost revenue, but this is where computer vision comes in.

Computer vision can detect worn or broken drill bits and shovel teeth, monitor drill and excavator activity, and track drill and excavator performance in real-time — boosting productivity and reducing costly interruptions. It sends real-time, proactive alerts to operators to prevent the overuse of equipment, reduces maintenance costs, and improves site efficiency. These optimizations not only improve the bottom line, but also limit unnecessary emissions and allow mines to be more sustainable.

Hauling

Ever-increasing costs for labour, materials, and energy are making it harder for mines to stay profitable. Fortunately, computer vision helps optimize and automate mine hauling with real-time data, eliminating manual bottlenecks and better allocating resources. This in turn helps reduce unnecessary emissions.

But how? Computer vision can monitor truck cycle timing, detecting any queues or idle trucks without loads. It can track ore and waste dumps to ensure no valuable ore is placed in a waste dump and vice versa. It can detect the loading (and misloading) of haul trucks, alerting management if any ore is placed incorrectly. It can prevent collisions between trucks, personnel, and equipment in busy open pit mines by tracking truck paths, identifying hazards in real-time, and alerting drivers or triggering autonomous braking.

Computer vision can also track machine status to resolve any slowdowns or breakdowns. It ensures key processes like haul, muck, and load activity are optimizing ore clearance and offers suggestions for future improvements through predictive and prescriptive analytics.

The technology provides real-time alerts for any bottlenecks, delays, or machine and labour slowdowns, so operators can act when needed and stay profitable.

Processing

Mineral processing is arguably the most important step in mining operations, when valuable ore is gathered and separated from waste material.

Computer vision can surveil conveyor belts in real-time and alert for any mechanical failures, tears, blockages, and spills. It can also notify if the primary crusher becomes blocked to prevent unnecessary downtime and processing from being slowed. Particle size distributions can be analyzed, preventing any oversized pieces from being passed further along in the mineral processing process.

Computer vision provides real-time alerts for any processing issues, so mines don’t forfeit precious time (and revenue). It automates inefficiency identification, so productivity is maximized and processing workflows streamlined.

Health and safety

Mining jobs are some of the most dangerous and injury-prone, so monitoring workers’ safety is essential. Furthermore, investors and customers are prioritizing environmental, social, and governance (ESG) factors more than ever before, with employee safety being a key focus.

Maintaining workforce safety while also scaling operations can be complex, but computer vision offers a solution. This technology can ensure personal protective equipment (PPE) compliance by automatically monitoring gear and alerting management of any workers not adhering to correct safety protocols. This can be done in tandem with facial blurring to protect worker privacy, solely alerting management to visit the scene and address any issues as quickly as possible.

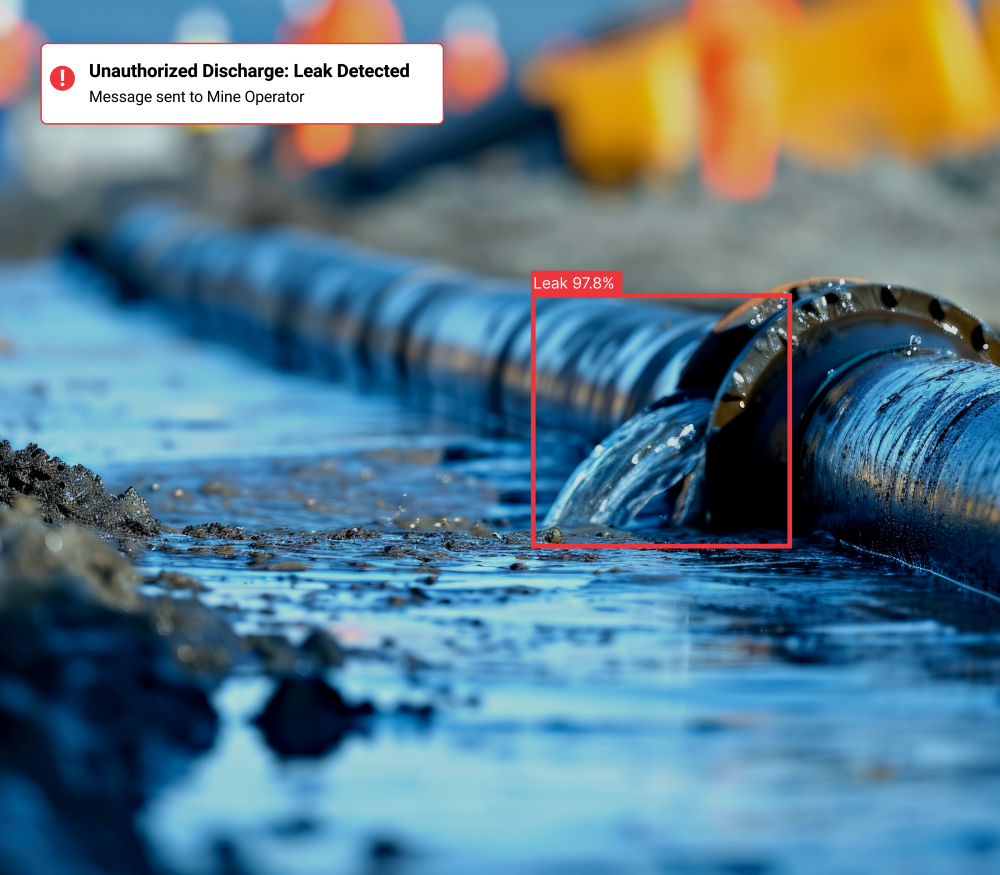

Computer vision can prevent safety breaches by monitoring hazardous zones as well. If workers enter restricted or unsafe areas, real-time alerts can be sent to mine operators to resolve breaches before they have the chance to potentially escalate. Fires, spills, and leaks can also be detected in real-time to proactively address safety and environmental hazards.

Computer vision’s automated monitoring allows mines to get real-time alerts for any issues that occur to keep their workers protected and comfortable.

Environmental monitoring

As sustainability and ESG demands rise, tracking the environmental health on and around mine sites is important for protecting workers’ safety, wildlife, and the mines’ reputations. Mines are also facing stricter environmental regulations than ever before, requiring immediate compliance to continue operations.

Computer vision can help tackle these pressures. This technology can monitor and count fauna to keep tabs on the environmental health around a mine site. It can also lower a mine’s environmental footprint by automating key sustainability processes like waste monitoring and energy management to reduce emissions and resource usage.

For example, it can detect any water discharge anomalies to prevent pollution and costly fines. By tracking the distribution of tailings material, any unplanned accumulations can be identified to protect the dam wall.

Computer vision provides real-time alerts for any environmental issues so they can be promptly addressed, and mines can stay productive.

Site security

Mine sites are large, targets of theft, and difficult to keep tabs on at all times. Traditional manual monitoring is both expensive and prone to error.

Thankfully, computer vision can help automate and protect site security, monitoring a mine site’s perimeter and sending real-time alerts for any unauthorized breaches or theft, so security can quickly respond to issues. Cameras placed around a mine site perimeter can detect any security breaches, and cameras placed around restricted areas and precious resources can alert for any pilfering and theft.

Computer vision’s real-time insights secure sites and valuable materials, while also protecting worker safety and keeping ESG goals a priority.

Computer vision is practical

Computer vision is key for mining enterprises of all sizes because it is practical. It shows leaders what is happening in their business as it happens — acting as a digital superintendent. It offers the actionable data needed to make immediate sustainability and operational improvements and stay ahead in such a competitive industry.

Building successful computer vision solutions is complex and time intensive, but end-to-end platforms exist where you can build, deploy, and manage applications in one place. Furthermore, if mining enterprises do not have the engineering talent to build solutions themselves, some computer vision providers will take over the entire process — constructing and deploying solutions for a mine’s unique needs and environment. Computer vision is the future of mining, and it is here to stay.

Comments