Alamos pioneers new water treatment approach

Alamos Gold’s Young-Davidson mine in northern Ontario. CREDIT: ALAMOS GOLD

Ammonia treatment in mining waters is attracting new interest and innovation.

Ammonia has a special status for miners, because it is toxic to fish at low concentrations in the unionized form, and because it is not removed in the most popular mine water treatment processes involving lime application.

Furthermore, last year new regulations were published in Canada that introduced an “end-of-pipe” effluent limit for unionized ammonia for new mines, or mines that are closed and reopened (CMJ, April 5, 2018). Formerly, many mines already needed to deal with ammonia to ensure they meet non-acutely toxic criteria, or to meet receiving water targets. Ammonia has commonly been found in mining waters as a residual of blasting compounds or as a by-product of cyanide use, so gold miners pay particular attention to it.

Historically, many mines have relied on natural degradation in ponds for the management of ammonia, however space limitations and these new regulations are motivating innovation. This article will outline a new approach to handling ammonia in mining effluents, which was pioneered by Alamos Gold at their Young-Davidson mine in northern Ontario. The new approach is a game changer for the industry in management of ammonia in cold water.

Natural degradation can take place through loss of ammonia to the atmosphere at high pH, or through biological oxidation by ubiquitous nitrifying bacteria, or through uptake by aquatic plants including microalgae. Operators in the past have noted that natural degradation of ammonia can be poor in gold mill tailings ponds, where metals and metal complexes can be present that are toxic to algae and other microorganisms, but polishing ponds, where metals are low, are important contributors to ammonia removal. In the Canadian context, the natural degradation processes are essentially focused on the ice-free months of the year, so this means that miners that rely on natural degradation need to provide large storage ponds to hold water through the winter. Gold miners, like Alamos, commonly see ammonia in tailings ponds rising under the ice in the winter and dropping in summer as the algae and bacteria grow more quickly.

Miners that are not able to rely on large ponds to encourage natural degradation of ammonia have either adopted the approach of pH adjustment, which converts unionized ammonia to ammonium (NH4+), or they have adopted some kind of water treatment that is able to meet total ammonia nitrogen (TAN) limits. Due to strict effluent limits, the latter approach is used at the Young-Davidson Mine. In other locations, wetlands have been used for TAN reduction, but like natural degradation in ponds, are most useful in summer, and typically requires large land areas. Miners that are contemplating TAN treatment are faced with an array of technologies. If trace metals are also requiring treatment, then a complementary metal removal process is required. Due to the array of options, then an unbiased water treatment assessment is needed to make informed decisions about a variety of treatment and management alternatives. Golder provided such an assessment when Alamos was looking for new ammonia management options at the Young Davidson Mine in 2017. Alamos preferred alternatives that are suitable for winter operaDaation in cold climates, and options that require a minimum of operator attention.

Alamos management was willing to consider thinking outside the box, that is, cold water nitrification technologies that had not yet been demonstrated in the mining space but demonstrated promise based on fundamental principles.

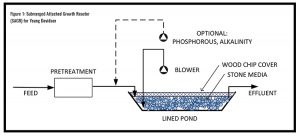

Figure 1.

The result of the water treatment assessment led to the selection of the Submerged Attached Growth Reactor (SAGR) technology. SAGR is an aerated rock-bed nitrification system provided by Winnipeg-based Nexom. Project experience for the technology came from across the continent, primarily in the municipal treatment sector, such as removing nutrients from the overflow of sewage lagoons. Operations experience with SAGR has been that once constructed, the system requires a minimum of supervision, but most importantly, it is capable of efficiently removing ammonia to low limits, in water as cold as 1°C. A key element of cold water operations is the establishment of a nitrifying biomass in the rock bed in warm temperatures, and careful attention to pre-treatment to remove substances which might harm the nitrifying bacteria in the SAGR. An illustration of the SAGR system is provided in Figure 1.

Golder’s water treatment assessment emerging technologies. The evaluation included the following options: natural degradation, Moving Bed Bioreactor (MBBR), struvite formation through electrocoagulation, breakpoint chlorination, air stripping, ion exchange (with several sub-alternatives for brine handling) and the SAGR. The assessment concluded:

- SAGR was the lowest net present capital and operating costs, compared to any option (apart from natural degradation) considering a treatment campaign of 2 million cubic meters over a two-year period.

- SAGR had relatively low mechanical complexity, and low operational labour input.

- The next best rated option was the MBBR, but such a system is not normally operated at 1°C, and requires a significant cost to heat the feed water.

- The electrocoagulation/struvite process provides another innovative technology in the cold water ammonia space. In the case of the Young- Davidson, an amendment of phosphorous would have been required to match the ammonia removal.

Following a successful pilot testing program for the SAGR in late 2017, conducted at the University of Winnipeg, the SAGR system was constructed in spring 2018, and was started up in late June.

The design took advantage of an existing polishing pond at the mine, which was converted to purpose, simplifying the project. The system was designed to handle two different water feed sources, through adjustment of the flow feeding the SAGR:

- A tailings pond feed water with temperatures between 1°C (winter) and 15°C (summer).

- A historic, flooded pit with temperatures consistently 3 – 8°C at depth, and up to 15°C in surface waters in summer.

Within about a month of starting the SAGR, the system was producing effluent that was well below the site’s target effluent target for TAN. The system was subsequently ramped up to a flow of 3700 m3/d (700 gpm) through the summer, limited by the capacity of a pretreatment process. Through the fall, as the feed water temperature dropped, then the flow was progressively reduced.

The SAGR was started up and run first using the pit water feed source, which was low in thiocyanate. However, in October, the SAGR received a feed containing an elevated thiocyanate concentration.

In spite of the cold feed water temperature, the system adapted to the new feed conditions within weeks, and demonstrated efficient SCN removal, simultaneously with TAN removal. The finding of cold water conversion of thiocyanate at this scale is significant, and would seem to show that the previously established biomass was capable of converting SCN inside the SAGR. This is believed to be the first case of thiocyanate treatment, in a SAGR and in cold water, anywhere in the world. Alamos plans to modify some of the upstream components in the spring of 2019 then put the SAGR through its paces, both for higher strength ammonia feeds, and higher thiocyanate loadings, with the advent of summer in 2019.

Michael Bratty, M.Eng. P.Eng., is a senior mine water treatment engineer with Golder, based in Vancouver. He can be reached at mbratty@golder.com or at +1 (604) 296-7348.

Comments