A new use for MBBR technology

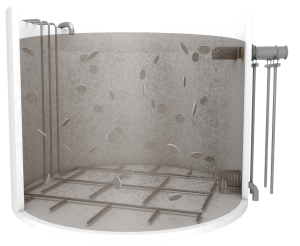

Veolia’s AnoxKaldnes moving bed bioreactor (MBBR) technology provides a resilient solution for biological degradation of ammonia. Credit: Veolia

The Canadian regulation for mining effluent discharge mainly focuses on toxicity of the final effluent to the receiving body. One of the main objectives of the regulation was for the water to be non-toxic for the greater daphnia (Daphnia magna) and for the rainbow trout – two surface-water fish species. There was, therefore, no possibility to discharge saline water because salinity is toxic to these two fresh water species. However, this situation changed in June 2018 as the Canadian water management regulation was amended and renamed the Metal and Diamond Mining Effluent Regulation. Among many changes, the amended regulation allows for discharge of a mine effluent in a marine environment by adding the threespine stickleback (Gasterosteus aculeatus), a brackish water fish, to the acute lethality testing protocol. Hence, acute lethality testing may be done either in saline water conditions with the threespine stickleback or in fresh water with the rainbow trout and the greater daphnia.

The amended regulation provides more flexibility with respect to water management for mines that have the opportunity to discharge in saline water.

Sources of toxicity

The toxicity of a mine effluent can be related to several parameters, most notably metals and ammonia. Metals removal is achieved by physico-chemical processes. However, ammonia is a complex toxicity source to address with standard physico-chemical methods. Ammonia treatment remains a challenge and few technologies are available as chemical and physical processes (e.g. the break point chlorination, stripping). In many applications, biological treatment is known to be a good solution to address ammonia toxicity. However, little reference could be found for ammonia removal in saline water effluents.

Biological treatment for ammonia removal

Biological treatment was intensively investigated in fresh water effluent. In surface water, ammonia removal can be addressed using a biological treatment such as a moving bed bioreactor (MBBR). Supported by more than 35 years of continuous research, development and process expertise, Veolia’s trademarked AnoxKaldnes MBBR is a compact fixed-film technology that provides a resilient solution for biological degradation of ammonia. It also offers a better resistance to toxic shocks and adapts to various operating conditions (moderate loading variations, cold water operation). An added benefit of applying the AnoxKaldnes MBBR for ammonia removal is that it has proven to require limited chemical dosages and maintenance. The MBBR has proven to be an interesting solution for Canadian wintery conditions in many mining applications.

Veolia conducted a laboratory study in collaboration with a northern mining site in order to determine if the MBBR technology could be applied in a saline water effluent. The objective of the laboratory study was to determine the possibility of operating a biological treatment in saline water conditions and to determine the influence of the water salinity on the biomass. The study mainly focused on the establishment of the complete nitrification of ammonia (from ammonia to nitrate) in saline water and to achieve a non-toxic effluent to the threespine stickleback.

Methodology

The mining effluent used for the laboratory study contained both high salinity and ammonia concentrations due to the use of explosives in underground mine operations. The salinity of the mine effluent was higher than the salinity expected in the sea. As such, the mining effluent was diluted to a salinity of 30 g/L using tap water, with a composition similar to surface water composition available on site. The biological treatment was fed with a mining effluent at 30 g/L of salinity.

A six-month biological treatment trial was conducted on the saline water effluent, with ammonia concentration up to 50 mg N/L (after dilution). The behaviour of the biomass growth in saline conditions as well as start-up strategies were the main focus of the development of this new MBBR application. The mining effluent was poor in bacteria, so a municipal sludge was used to seed the biological treatment. While this is probably not mandatory, this helped speed up the process start-up. In order to help the development of an adapted biomass, the mine effluent was diluted to brackish water conditions to start the biological treatment.

Key features of the saline biological treatment operation

Ammonia oxidation to nitrite was quick to establish itself in brackish water conditions, as is often observed in surface water applications. However, when salinity was increased too quickly, it resulted in the loss of ammonia removal and the detachment of all the biomass on the MBBR carriers. A gradual increase in salinity to the biological system was required to prevent losing ammonia oxidation efficiency. After an appropriate rate of salinity increase, the AnoxKaldnes MBBR achieved stable ammonia removal efficiency at 30 g/L of salinity.

The salinity was shown to have a greater impact on the bacteria responsible for the nitrite oxidation; complete nitrite oxidation to nitrate was achieved after six months of operation. During acclimation of the nitrite oxidizing bacteria, ammonia loading was slowly increased. At the end of seven months of operation, final ammonia loading was similar to the ammonia loading usually applied to a newly commissioned AnoxKaldnes MBBR system in a surface water application.

Once the biological process was fully acclimated, the biologically treated mine effluent was subjected to a toxicity test. The result has shown the effluent not to be acutely lethal to threespine stickleback (0% mortality). The final ammonia and nitrite concentrations were below 1 mg N/L.

New leads to explore

In the coming years, reduction of nitrate concentration in the mine effluent will also become an important part of pollution reduction. Nitrate is indeed known to be an important source of eutrophication in natural surface water, thus leading to more stringent regulations to limit the impact of industrial activities on the environment. During acclimation of the nitrite oxidation bacteria, a side test was conducted to determine the efficiency of denitrification (biological reduction of nitrate to nitrite and of nitrite to nitrogen gas). The side test was run for a limited period (two months). Through these two months, nitrate reduction to nitrite was observed but reduction of the nitrite concentration was only partial. Since an extended acclimation period was required for nitrite oxidation in the nitrification reactor, Veolia is expecting a similar conclusion for the denitrification success in saline water effluent.

Conclusion

The testing completed in Veolia’s laboratory has shown great promise for ammonia removal in a saline water mine effluent and highlights the possibility to provide a complete nitrogen removal biological system (nitrification + denitrification) in saline water effluent. Once the start-up of the process was well understood, the efficiency of the MBBR system proved to be as efficient as surface-water applications. Thus, the AnoxKaldnes MBBR technology can provide a robust and low-maintenance solution for nitrogen removal in saline water mining application.

Comments