A highly responsive conveyor belt tracker

The next generation of tracking technology for a global marketplace has launched. Martin Engineering has been a global innovator in the bulk material handling industry for more than 80 years, developing new solutions to common problems and participating in industry organizations to improve safety and productivity. The highly responsive Martin Tracker HD (heavy-duty) belt conveyor alignment system was designed with widely available plate steel to increase availability and affordability. A mistracking belt produces excessive spillage, which increases labour costs for cleanup and may cause contact with the mainframe, seriously damaging both the belt and the structure and increasing the potential for a friction fire. The new Martin Tracker HD upper and lower units provide immediate, continuous, and precise adjustment of the mistracking belt. This results in greater productivity with reduced downtime from both equipment replacement and spillage cleanup for a lower cost of operation.

Most OEM mistracking devices are only designed to prevent contact with the stringer and do not realign the belt, resulting in operators spending a lot of time monitoring the system and adjusting idlers to achieve consistent alignment. According to Dave Mueller, product manager for Martin Engineering, “with enough manual adjusting, operators find that idlers must be recentered if there is a change in cargo characteristics or to install a new belt. The Tracker HD automates the alignment process, eliminating the need for constant monitoring and manual adjustments, thus reducing the labor and downtime for maintenance.”

Where the new belt Tracker HD’s unrivaled precision comes from

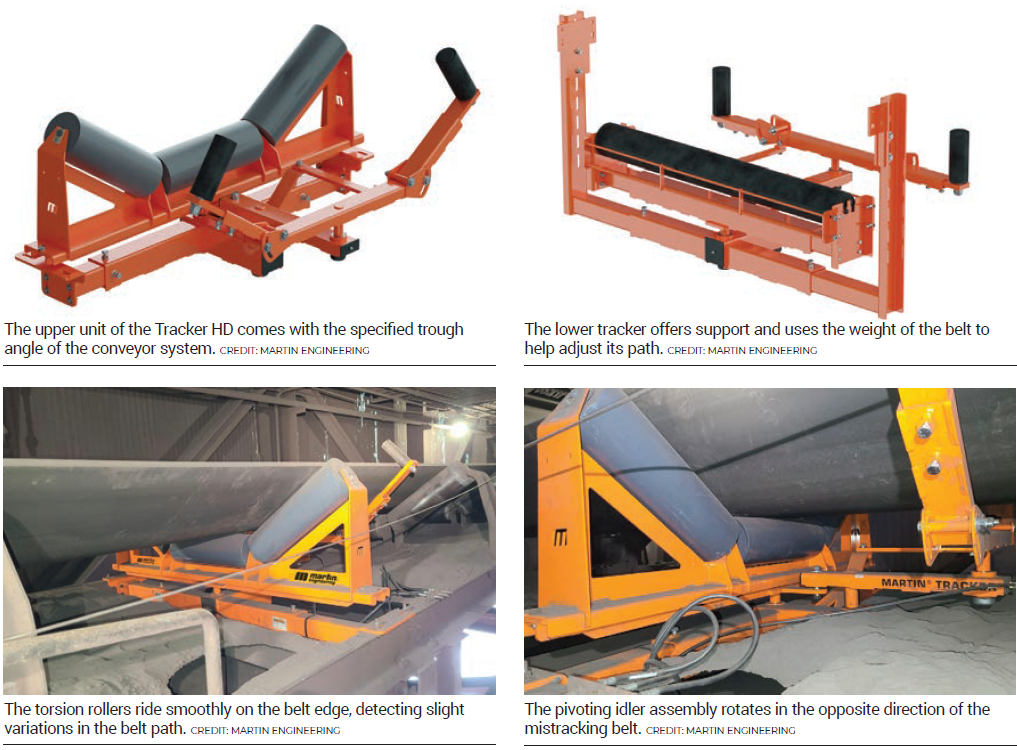

Sensing rollers ride either side of the belt edge and are attached to the end of an arm assembly. As the rollers detect slight variations in the belt path, the force of the wandering belt causes the arms to automatically position a pivoting idler in the opposite direction of the misalignment. The lever action requires less force to initiate the correction and only slight adjustments mean the consistent contact between the belt and idlers reduces the energy needed to bring the belt back into alignment.

“Certain countries cannot buy square tubing, so we are now manufacturing the equipment from readily available plate steel without any changes to the performance or life of the unit,” Mueller pointed out. “This allows the Tracker HD to be produced and supplied across all global business units,” added Mueller.

Compatibility with most belt conveyor systems

Easy to install and designed to withstand the stress associated with wider, thicker belts moving at higher speeds and carrying heavier loads, the Tracker HD is suitable for a belt thickness up to 28.5 mm and speeds up to 4 m/s. Both the upper and lower units accommodate belt widths of 915 to 1828 mm with an effective tracking distance of 45.72 m.

Available in 20-, 35-, and 45-degree trough angles, there are options for the addition of a Martin Trac-Mount Idler, which allows the entire troughed idler unit to be slid away from the mainframe and safely serviced from outside of the system by a single worker, thus greatly reducing the amount of labour and maintenance time for the replacement of broken or frozen idlers. This is an additional safety feature. Rubber-lagged rollers are available on the lower tracker and a grease kit for the upper and lower assemblies. However, the unit is “not suitable” for reversing conveyors, belts with substantial rollback, or paddle or chevron belts.

Key is proper placement

The Martin Tracker HDs must be installed after the load zone on belts that are wider than 610 mm, with additional units placed down the system to keep the belt centered and tracking. By placing an upper unit before the discharge, the belt is securely centered on the head pulley, allowing for optimal belt cleaning with maximum cargo discharge.

Regardless of the conveyor, the lower tracker is redesigned to include a unique safety feature. Since the return rollers usually detach and drop, creating a serious safety issue, the Martin Tracker HD has been equipped with safety guarding on the steering roll to prevent the roller from coming off or putting workers in harm’s way. On the return, it is recommended to place a tracker after the discharge zone or take-up pulley, as well as periodically down the system depending on length. To support an efficient loading process and ensure centered loading, the belt must enter the loading zone aligned, so installing a lower unit that is approximately five times the belt’s width in distance from the tail pulley.

Tested and approved in the field

The basic design of the Martin Tracker HD is like that of its predecessors with square tube construction. Consequently, the testing focused on performance, durability, and installation time. Tested in bulk handling operations including mining and cement where mistracking leading to spillage had historically been a concern, the unit performed up to Martin Engineering’s high standards.

“Martin Engineering believes safety should be a core function in any conveyor accessory we design, and the Tracker HD is no different,” Mueller said. “By automating consistent belt tracking, this solution reduces equipment wear, maintenance time, and downtime. These factors lower the cost of operation, offering the best return on investment of any tracker on the market,” he concluded. CMJ

Comments