A Canadian success story in West Africa

Reporting on the Fortuna Silver Mines’ Séguéla mine visit

By Tamer Elbokl, PhD

Invited by Fortuna Silver Mines, on June 4, 2023, I embarked on a trip to the beautiful West African country of Côte D’Ivoire to visit Fortuna’s new Séguéla gold mine in the north of the country. Twenty-six hours later, I arrived in Abidjan, and was accompanied by the most dedicated staff to my hotel in the city. The trip

to visit the mine site started by a 2.5-hour helicopter ride. Upon arrival, the group was welcomed by Fortuna executives and staff and debriefed on the schedule of the visit, which started immediately by visiting the plant.

Flashback

In July 2021, Fortuna Silver Mines and Roxgold completed a combination to create a global premier growth-oriented intermediate gold and silver producer. Consequently, Fortuna inherited the Séguéla project, located 480 km north-west of Abidjan, when it acquired the Canadian gold miner. The deal resulted in Fortuna, a gold and silver producer with operating mines in Mexico, Peru, and Argentina, gaining a strong foothold in West Africa. According to Jorge A. Ganoza, president, CEO, and co-founder of Fortuna, “The business combination creates a low-cost intermediate gold and silver producer with four operating mines (at that time) and a permitted development project (Séguéla mine). The company will benefit from a robust exploration pipeline and expanded presence in the Americas and West Africa, two of the fastest growing precious metals producing regions.”

In September 2021, Fortuna made the decision to proceed with the construction of an open pit gold mine at Séguéla, with sustainability being an intrinsic part of the design, construction, and future operation of the project.

Location

The Séguéla mine is in the Worodougou region of the Woroba district, Côte d’Ivoire, approximately 480 km from Abidjan. From Séguéla, the property is accessed via 40 km of unsealed roads. The Séguéla mine operation permits combined cover an area of 62,000 hectares.

Exploration and reserves

Séguéla mine exhibits excellent grades, low operating costs, and good growth potential. Séguéla has compelling economics, with a nine-year mine life in reserves. The initial six years are expected to report 133,000 oz. of gold production annually. With the total initial capital investment of US$173.5 million, the fast-tracked construction schedule was approximately 20 months and ramp-up to name plate capacity of 3,750 t/d is expected in the third quarter of 2023.

The mine is expected to produce between 60,000 to 75,000 oz. of gold in 2023 at an all-in sustaining cost of between US$880 and $1,080 per oz. of gold.

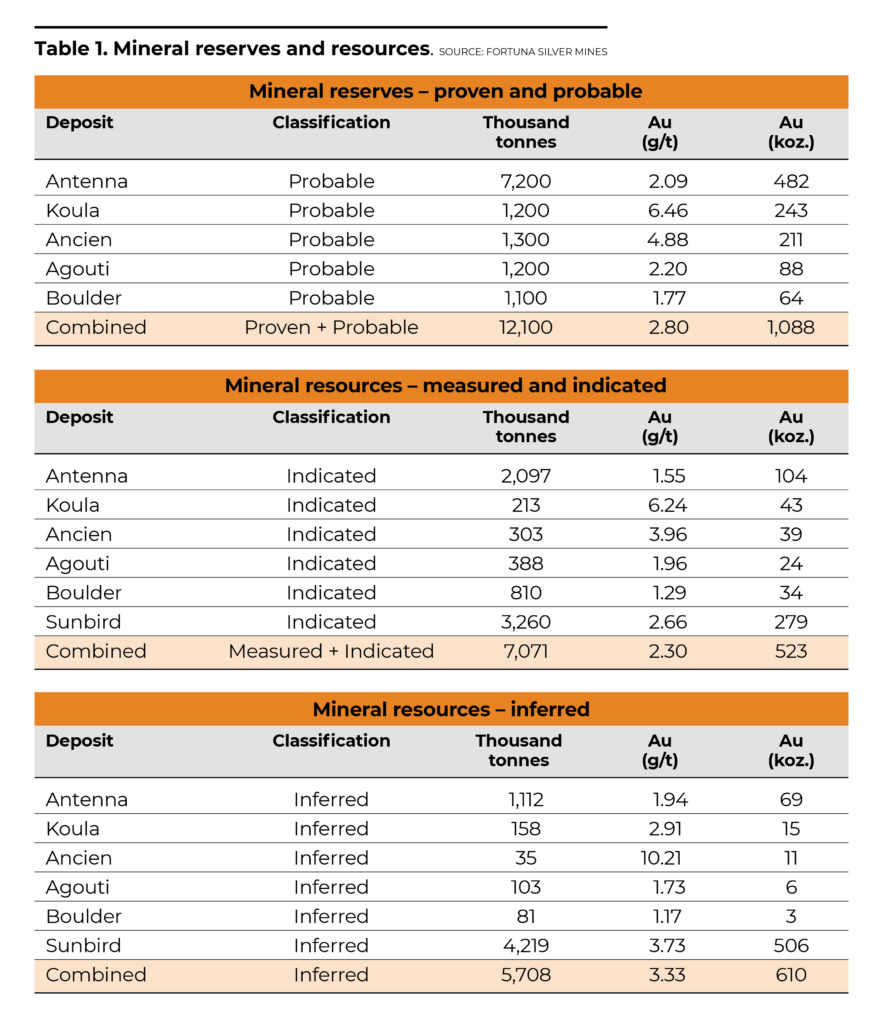

Mining activities at Séguéla include the simultaneous exploitation of the main Antenna deposit and the satellite deposits at Koula, Ancien, Agouti, Boulder, and most recently Sunbird, using open pit methods.

In 2022, Fortuna announced an inferred resource for the newly discovered Sunbird deposit which is not included in Séguéla’s current mine plan. This discovery is located just a couple of kilometres from the plant site. Table 1 shows the current mineral reserves and resources; numbers are likely to grow as Fortuna continues conducting exploration work. The Sunbird deposit is planned for conversion into mineral reserves by Dec. 2023.

The processing plant

The processing flowsheet, shown to us during the pre-tour presentation, comprises conventional crushing, milling, gravity recovery, a carbon in leach (CIL) circuit, carbon elution, and a gold recovery circuit. Felix Asamoah, the metallurgy superintendent at Séguéla mine, started our plant tour by stating, “the process starts by running the raw material through the crusher. We have a simple crushing circuit with just one-stage crushing, and from there, the material is transported on the conveyor to the milling area. It is also a simple milling circuit.

A SAG mill which is in closed circuit with cyclones and a gravity circuit.”

The CIL circuit has seven tanks, each has a capacity of about 700 m3. The first tank is only for leaching; it is where the cyanide (NaCN) is added, and it starts dissolving the gold in the slurry. The six other tanks have activated carbon added into the cycle. While the cyanide is dissolving the gold, the activated carbon is absorbing the gold from the solution.

Each equipment can be monitored from the control room, and there are selected process parameters that can be monitored from there in a single view. The carbon is recovered through the acid wash process/column to clean it from contaminants, then flown into an elution column. In the elution circuit, a solution that contains caustic soda (NaOH) and cyanide is run through the carbon bed to take the gold off the carbon into that solution. While the fresh, regenerated carbon is sent back to the CIL circuit, the solution is sent to the gold room through the ICR Electrowinning cells, which have positive and negative contacts, and the gold in the solution deposits on the cathode.

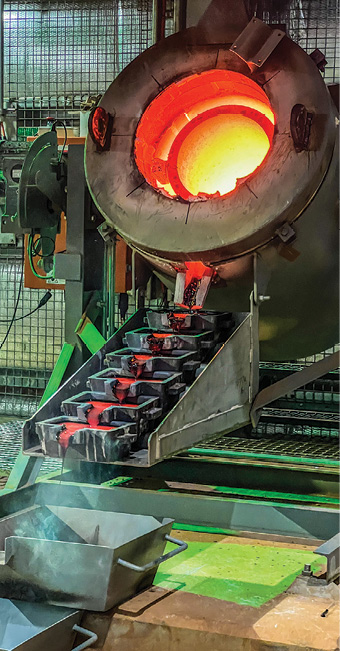

pour. CREDIT: TAMER ELBOKL

The gold pour

In May 2023, Séguéla poured its first gold on-time and on-budget, and consequently became Fortuna’s fifth operating mine.

We attended the second gold pour during our visit, as evident from the photo of the author of this article with a big smile holding a more than 700 oz. gold bar from the pour.

Tailings management

David Whittle, chief operating officer, West Africa, at Fortuna Silver, explained that the tailings storage facility is constructed as a side-valley storage facility formed by two multi-zoned earth fill embankments, designed to accommodate 13 million tonnes of tailings, and built using the downstream construction methodology. Water storage dam (WSD) reserves are at levels above requirements, and the plan is for the dam to reach 18 metres in height.

Social responsibility and community relations

When it comes to community relations, Fortuna’s objectives are to build trust, manage expectations, and positively impact communities. “The villages of Tiéma, Kouégo, and Bangana, located several kilometers from the mine site, are the closest settlements. Trust and strong relationships established with the local communities are pivotal to the success of the project development and its upcoming operation,” said Carlos Baca, director of investor relations at Fortuna Silver Mines. “We have been building this trust and cultivating these relationships for over five years. In 2022, we employed 153 community members from local communities, and we also partnered with 10 local suppliers,” Baca added. CMJ

Comments