A bigger vision for better use of the Earth’s resources

The mining sector requires constant innovation if it is to optimize production, lower costs, and, most importantly, improve safety for workers. Artificial intelligence (AI) and machine learning (ML) technologies can make a big difference and help businesses adapt even in the face of unpredictable events.

Veracio is a stand-alone entity, infused with Boart Longyear’s rich legacy of innovation, and sits at the intersection of technology and orebody science

Recently, Boart Longyear (the world’s leading provider of drilling services, drilling equipment, and performance tooling for mining and drilling companies) announced that its Geological Data Services division will operate as a separate entity called Veracio. The new entity is set to combine science and digital technologies in a single, integrated platform and help mining companies get more value from their orebody data faster, while mitigating the environmental impact of their decisions.

Veracio’s technologies and platform, the result of a decade of testing and development in sensing, automation, and AI technologies, empowers miners to dig deeper into data, accelerating exploration and making better decisions that result in economically efficient operations and reduced waste. Powered by Boart Longyear’s award-winning Geological Data Services integrated technology platform, Veracio will support the growing global need for critical minerals by championing an approach to orebody science based on speed and sustainability.

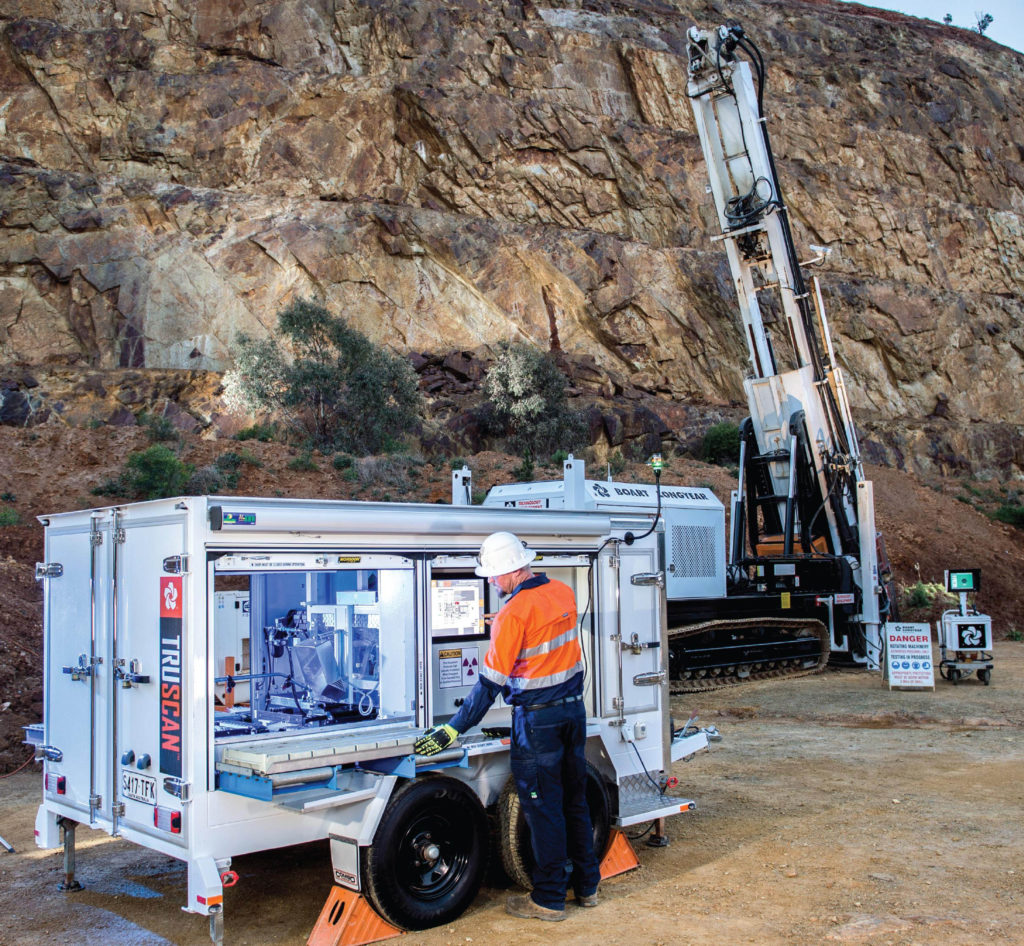

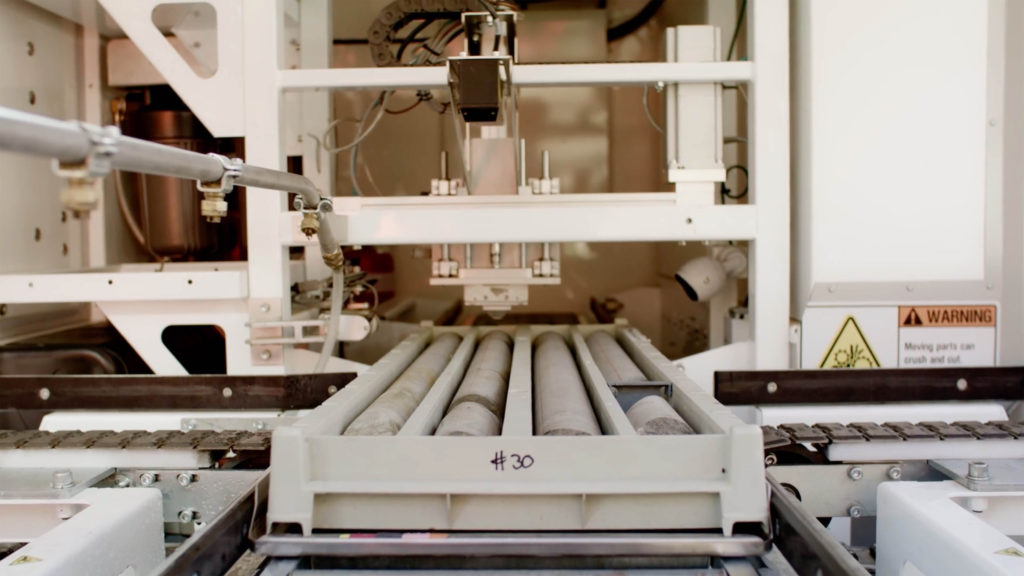

Veracio’s (originally Boart Longyear’s) innovative in-field drill sample scanning system, TruScan, has been named “mining innovation of the year” at the prestigious Mines and Money conference in London, held in December 2022. This recognition highlights Veracio’s commitment to providing cutting-edge technologies that drive productivity and efficiency in the mining industry.

A few weeks ago, I caught up with Veracio’s newly appointed CEO, JT Clark (JTC) and chief innovation officer, Mike Ravella (MR), to discuss Veracio’s recent “graduation from Boart Longyear,” as Clark likes to call it.

Veracio, a wholly owned Boart Longyear subsidiary, offers mining clients a range of solutions that improve, automate, and digitally transform their orebody sciences. Championing a modern approach through a diverse product portfolio by fusing science and technology together with digital accessibility, Veracio leverages AI and advanced analytics to accelerate real-time decision-making driving efficiency in mineral exploration and mining which is moving mineral resources forward.

CMJ: To start the conversation, my first question to both of you is how did you end up in your positions as CEO and CIO of the new company?

JTC: For most of my career, I worked at BCG, a prominent consulting firm and in my most recent position, I served as the global leader of BCG’s mining practice. Six years ago, I shifted my focus to applying AI and advanced technologies to optimize mining operations, creating BCG Phosa, a real-time optimization tool for mineral processing covering the entire value chain. Although it has delivered significant improvements in production, we discovered that the accuracy and granularity of orebody knowledge were limiting factors. AI requires detailed and high-quality information to identify smaller differences and make finer adjustments and mining companies were not capturing sufficient detail about the orebody to support AI.

In my consulting work with Boart Longyear, I learned about the range of technologies under the Geological Data Services division and their ability to provide accurate and detailed orebody knowledge. I was amazed by their solution which had previously hindered my AI deployment work. With their technology, I also saw the potential to improve the production and recovery of critical minerals throughout the life of the mine. This is how I ended up at Veracio, this was a natural move for me, and I believe the products and services we offer are critical in driving accurate and detailed orebody knowledge for mining optimization.

MR: I am a hydrogeologist by trade, and in my background in contaminant hydrogeology, we used real time digital sensing for dynamic environmental site investigations to provide information about contaminant source areas and plumes. I worked in environmental and then mining related drilling for Boart Longyear. When I entered the mining field, I found orebody knowledge definition archaic in the mining space. After running several drilling businesses for Boart Longyear in the U.S. and then Australia, I started Geological Data Services from an idea for Boart Longyear in 2015 when we started to look at digital sensing and AI and applying it to mineral exploration and mining, and that is how Veracio started.

“I consider Veracio a graduation from Boart Longyear. The AI/ML-based technologies under the Geological Data Services division have matured and deserve recognition and attention of their own.”

JT Clark, CEO of Veracio

CMJ: So, what do you like most about your job?

MR: Working with a group of people and clients who truly believe and are 100% focused on changing mineral exploration and mining through digital sensing and AI and knowing that the work we are doing is providing critical mineral solutions for humanity.

CMJ: Can you please talk to us briefly about Boart Longyear’s decision to operate its Geological Data Services division as a stand-alone entity called Veracio, what was the reason for the decision?

JTC: Boart Longyear is an ideal birthplace for the development of innovative technologies and capabilities for the mining industry. Developing such technologies requires a conducive environment, and Boart Longyear’s 127 years of experience in the most challenging operating conditions provide just that. I consider Veracio a graduation from Boart Longyear. The AI/ML-based technologies under the Geological Data Services division have matured and deserve recognition and attention of their own. Furthermore, technology development is a distinct business from drilling services, and it is essential to establish new processes for funding and operation to support Veracio’s technology objectives while working closely with the engineering and operating expertise at Boart Longyear. We are providing these technologies with an appropriate platform to grow and serve the industry.

MR: Boart Longyear is focused on providing safe productive drilling to the mining industry. At the end of the day, the product of Boart Longyear’s services and products is quality drill samples. Mining companies require these drill samples to understand the earth. A natural progression for Boart Longyear is Veracio, where we are focused on unifying orebody knowledge and giving mining companies information about the earth at high density in real time.

CMJ: Most people tend to not associate the mining industry with such things as advanced systems technology; however, in your opinion, how can artificial intelligence transform the mining industry?

JTC: This is a common misconception, as the mining industry has been investing in building advanced analytics and AI capabilities for some time now. However, compared to tech companies, the mining industry falls behind in terms of AI development. The reason is that mining poses unique and complex challenges that simplistic solutions of the first generation of AI were not capable of solving. AI had to continue to evolve and mature to effectively support the mining industry.

AI has already started to transform the mining industry and will continue to play a central role in its future. Primarily, this is because the world demands more critical minerals that the mining industry must supply, while at the same time mining companies must operate with a smaller carbon and environmental footprint. With declining head grades and increasing geological difficulty, new discoveries are geographically remote, more challenging to access, and often in challenging geopolitical environments. The traditional mining and exploration toolkits are ill-equipped to satisfy these demands. The mining industry significantly benefits from AI, as it equips them with the necessary tools to improve performance, automate processes in challenging environments without risking human lives, and achieve a higher level of accuracy and precision.

For example, mines that have been operating for decades have historically sent ore to waste that would now be considered economic ore. However, upcoming mining projects involve mines that might only have a 10- to 20-year mine life, are deep underground, and are hard to access. To overcome these challenges, the mining industry needs a more advanced toolkit that allows for more accurate, precise, and deliberate resource recovery. There is no margin for error, as valuable resources cannot be wasted and left in a pile for future generations to recover. They must be extracted today.

MR: I agree, and I see it growing more and more each year. It is clear that the future of mining will be very different from the past. Feedback and actions from early adopters and mining companies clearly define this.

CMJ: Can you please explain the role of AI and ML in improving mine safety?

JTC: Improving the understanding of the orebody and automating tasks using AI are two primary ways to operate more safely in the mining industry. By better understanding the structural geology of the orebody using AI, we can reduce the risk of bench failure and improve the quality of mine planning.

Additionally, by automating tasks that previously required human intervention using AI and other technologies, we can remove the person from dangerous environments and eliminate risk. For example, automating rod handling on drilling rigs which is one of the most injury-prone activities. By using AI to capture in situ geological information, we can reduce the number of times we have to handle rods, ultimately taking humans out of harmful activity.

Our goal is to reinvent workflows and activities that have been in use for decades and create safer and less vulnerable options.

MR: Digital sensing allows the mining clients to be bionic. They can work remotely and reduce exposure. The future mine site geologist will be far more accurate, consistent, and efficient. They will also be able to be on site less through digital sensing, software, AI, and ML.

CMJ: How can ML and AI maintain the operation and performance of mining machines using predictive maintenance?

MR: At Veracio, we utilize ML and AI to drive orebody discovery, definition extraction, and processing. Knowing what is in the ground and the parameters required to extract and process early and at high definition allows the mining company to make rapid decisions creating enormous value.

TruScan station. Credit: Veracio

CMJ: Finally, how can Veracio help its mining customers meet the unprecedented minerals demand that is fuelling the transition to a more sustainable economy?

JTC: Veracio’s primary mission is to enable (i) a bigger vision, facilitating the transition to electrification and a more environmentally friendly world; (ii) smarter data, providing the right information at the right time for informed decision-making; and (iii) a smaller environmental footprint, achieved by improving mine design accuracy, reducing the impact on the environment, improving biodiversity, and lowering carbon footprint.

As the demand for critical resources in the world increases, it is becoming harder to discover new deposits. To make new discoveries economically viable, increased precision is required, and the margin of error must be reduced. At Veracio, we do not just provide data but also analytical tools to support the next generation of accuracy, making decision-making more efficient and accurate, and enabling more efficient execution of mining agendas.

Comments