Electra begins feasibility study for battery recycling refinery

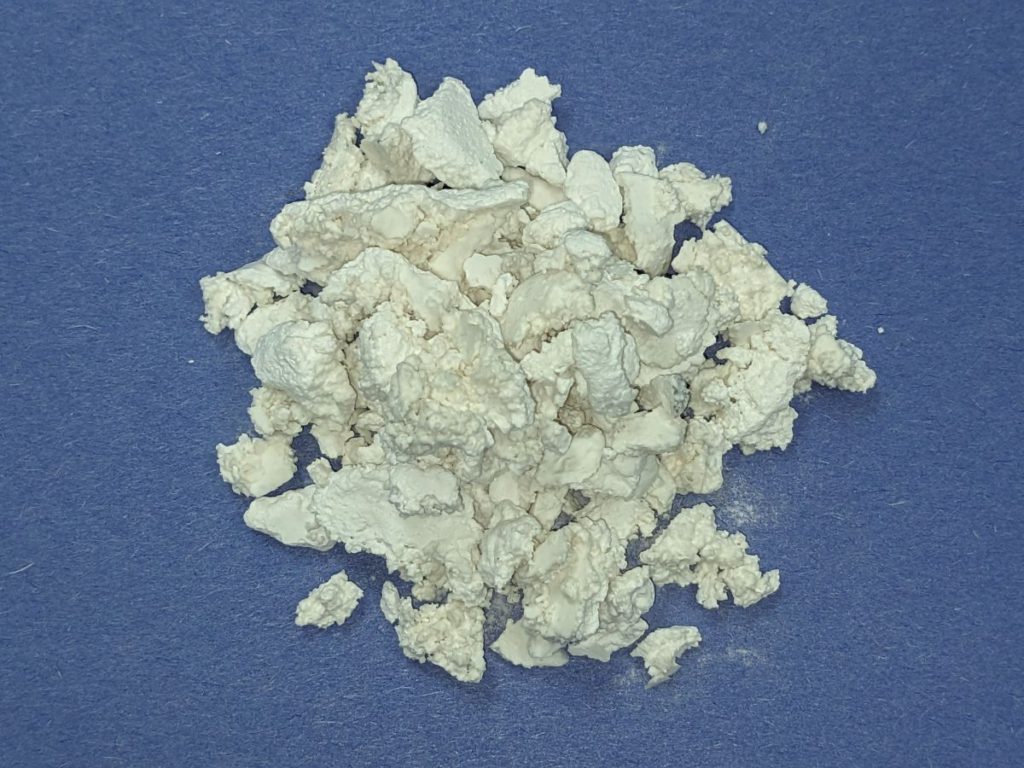

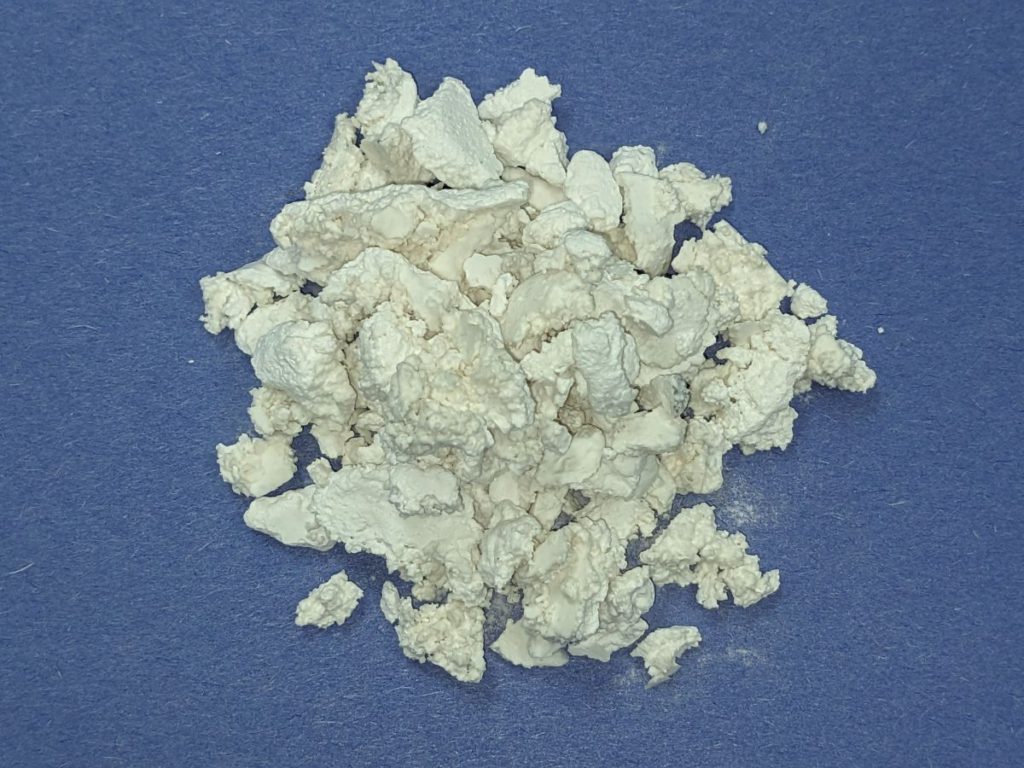

Electra Battery Materials (NASDAQ: ELBM; TSX-V: ELBM) commenced a feasibility level engineering study to build a battery recycling refinery adjacent to its cobalt refinery north of Toronto. The study will build on the technology and expertise accumulated during a year-long black mass recycling trial, whereby Electra produced technical grade lithium and a nickel and cobalt product from end-of-life lithium batteries.

Electra is establishing relationships with North American battery makers, offering a closed-loop partnership to return critical minerals back into the domestic supply chain. Currently, most of the company’s black mass produced from battery scrap is shipped to Asia for refining. This situation deprives automakers of the ability to control their critical minerals supply chain. Electra’s joint venture with the Three Fires Group, Aki Battery Recycling, will build a pretreatment facility for battery scrap, with the resulting black mass material shipped to Electra for refining.

Mark Trevisiol, Electra’s vice president of project development, commented. “Having developed a proprietary hydrometallurgical process, this feasibility study is a critical step in advancing towards a commercial recycling facility. It builds on the knowledge gained from our previous 40-tonne demonstration plant and allows us to optimize our processes for a scalable commercial operation. As a first mover in North American cobalt sulfate production, we are leveraging our expertise in the domestic refining of black mass and further solidifying our leadership in sustainable battery material solutions.”

Dr. George Puvvada, Electra’s vice president of metallurgy and technology, added, “At Electra, we are applying in-house innovation and technology in an incremental fashion to our existing hydrometallurgical process. This approach is about leveraging a strong, established foundation and the expertise of our experienced team to minimize risk. By doing so, we enhance efficiency, create higher-value products, and reinforce our position at the forefront of the battery materials sector.”

Electra has retained Green Li-ion to assist with the engineering and feasibility studies. Green Li-ion is a U.S.-based company in the business of providing engineered services and recycling technology solutions. Green Li-ion also has an operating black mass processing facility in Atoka, Oklahoma. Subject to the outcome of the feasibility study among other considerations, Electra may elect to purchase processing equipment through Green Li-ion for operation at Electra’s refinery site in Ontario.

Electra CEO Trent Mell said, “Electra’s core strategy is to reduce North America’s reliance on critical minerals from China by building a reliable and resilient domestic supply chain. Through our proprietary hydrometallurgical process, tailored to meet the needs of a growing recycling market, we have consistently demonstrated the capability to produce high-quality, saleable products, including technical-grade lithium carbonate, nickel-cobalt MHP, and graphite.”

In 2023, Electra commenced the processing of 40 tons of black mass at its refining complex north of Toronto to trial its proprietary recycling process. In June of 2024, the company received C$5 million from Natural Resources Canada to accelerate the next phase of its recycling project. The company intended to demonstrate on a continuous basis that Electra’s hydrometallurgical black mass process is scalable, profitable.

Electra’s immediate priority is to complete construction of North America’s first battery grade cobalt refinery. The company’s longer-term vision includes battery recycling and nickel production, thereby onshoring additional critical mineral refining processes needed for the North American electric vehicle battery supply chain. More information is posted on www.ElectraBMC.com.

Comments