Bridging the data confidence gap in underground mining

The mining sector is currently navigating challenges and embracing opportunities with the integration of modern technologies. Prioritizing the safety of miners remains paramount while simultaneously aiming to boost production, curb greenhouse gas (GHG) emissions, and decrease energy consumption. At the core of these efforts is the ability to manage and leverage the immense volume of data generated by modern mining operations. Transforming this data into actionable insights is key to overcoming these challenges and unlocking new opportunities.

The data dilemma in mining

Ensuring the safety and well-being of miners is the top priority in underground mining operations. One important safety measure is the use of advanced Industrial Internet of Things (IIoT) sensors to monitor air quality, detect gases, and track real-time conditions. However, the quality of the data generated can be flawed, leading to delays in identifying safety issues or ignoring alarms altogether. The absence of high-quality real-time data increases the risks for miners.

Since reaching its peak in the 1990s, mining productivity has declined. This can be partly attributed to the growing complexities of mining operations, which have resulted in data being dispersed across various systems, presenting a significant challenge. The segregation of data has led to the loss of valuable insights and missed opportunities for optimization within the industry.

The mining sector contributes significantly to GHG emissions through its energy activities. Stricter environmental regulations require monitoring and reporting of energy use and emissions. Integrating data from various sources is crucial for compliance and sustainable practices. The challenge lies in analyzing this data to make informed decisions that balance objectives and operational effectiveness.

Energy costs are a substantial part of mining operational expenses. Traditional ventilation systems lack dynamic adjustment capabilities, leading to inefficiency, higher energy consumption, increased costs, and a larger environmental footprint. Without data-driven insights, opportunities for optimizing energy use and implementing predictive maintenance are missed, causing further inefficiencies and unexpected downtimes. Additionally, the inability to measure and refine system performance means ongoing inefficiencies persist, hindering potential cost savings and sustainability improvements.

Utilizing data for practical insights

The key to overcoming these challenges involves eliminating bad data and converting the remaining dataset into actional decisions through advanced data management and analytics. To do this, mining companies must implement modern solutions to tackle the issues.

Predictive maintenance (PdM) processes leverage real-time data analysis to anticipate equipment failures in advance. This proactive strategy enables scheduled maintenance, minimizing downtime and prolonging equipment life. Real-time data analysis helps proactively identify problems, ensuring smooth and effective operations. For instance, sensors on equipment can deliver data streams that are analyzed in real time to predict potential component failures, enabling timely maintenance and minimizing costly downtimes.

Digital task management (DTM) platforms consolidate information from sources into a system that offers a comprehensive view of operations. This holistic perspective supports decision-making, streamlined processes, and enhanced productivity.

DTM systems support real-time monitoring and management, ensuring all aspects of mining operations are optimized and aligned. By consolidating data points into a platform, mining companies can eliminate inefficiencies and guarantee smooth operation.

Edge-based data analysis processes information directly from where it originates, reducing delays and enabling responses to changing circumstances. This is especially vital in mine ventilation, where swift adjustments to airflow and quality are essential for miner safety and operational effectiveness. Processing data instantly, edge-based analysis facilitates management and quick decision-making. For example, sensors at the edge can promptly adjust ventilation systems based on real-time air quality readings to maintain conditions for miners.

Analytics can uncover patterns and trends within data that are not immediately obvious. These insights drive decision-making, empowering mining operations to streamline processes, cut costs, and enhance performance. By focusing on insights, mining companies can shift from reactive management to addressing issues before they escalate. This analysis allows for enhancements that can increase productivity and lower expenses.

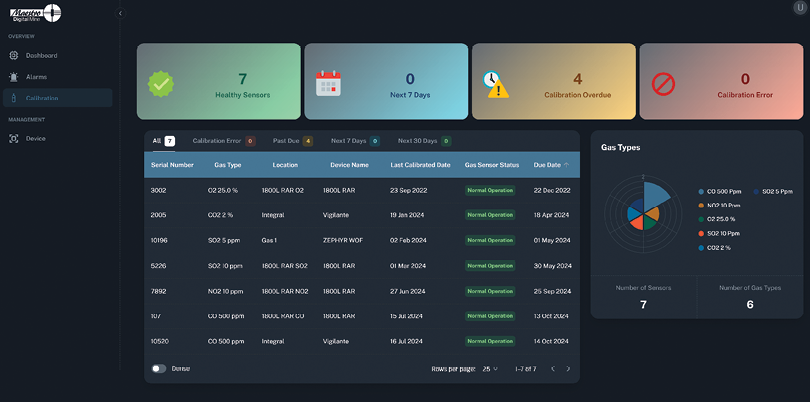

Introducing Duetto Analytics

Maestro Digital Mine has developed Duetto Analytics to ensure the reliability and relevance of data for making crucial decisions that impact worker safety and operational efficiency. The system acts as a bridge between IIoT devices and critical decision-making processes. Utilizing proactive and predictive maintenance strategies ensures that only accurate and relevant data informs maintenance schedules and operational decisions. This proactive approach minimizes unplanned downtimes, extends equipment life, and enhances overall efficiency.

A standout feature of Duetto Analytics is its capability to predict sensor failures, allowing for timely maintenance and reducing costly disruptions. By optimizing maintenance schedules, Duetto ensures continuous, efficient operations and cuts unnecessary costs. Additionally, Duetto Analytics streamlines workflows through its digital task management functionalities, improving coordination among departments and aligning efforts with overall organizational goals.

By handling data at its origin, Duetto Analytics minimizes delays and enables swift responses to changing conditions. This is vital for mine ventilation, where sensors can quickly adjust airflow and air quality, ensuring safe and efficient working conditions. This enhances safety and conserves energy by running ventilation systems only when necessary, reducing operational expenses and environmental impact.

Duetto Analytics uncovers hidden patterns in data, empowering mining operations to address inefficiencies, cut costs, and improve performance proactively. This transition from reactive to proactive management helps tackle challenges before they escalate, increasing productivity and reducing expenses.

Furthermore, Duetto Analytics provides a competitive edge by helping mining companies meet regulatory standards and sustainability goals. Its advanced features monitor and report energy usage and emissions, ensuring compliance with environmental regulations. Duetto Analytics supports sustainable mining practices by optimizing energy consumption and reducing GHG emissions.

Using proactive and predictive maintenance strategies, Duetto Analytics builds user confidence in the data, ensuring that decisions are founded on precise, dependable information. By translating this data into actionable decisions, mining operations can improve safety measures, boost productivity, manage operational impacts, and reduce energy costs. By incorporating predictive maintenance features, digital work management systems, and on-site data analysis, Duetto Analytics equips mining operations with the essential tools to navigate this landscape confidently, fostering a more efficient and sustainable mining environment.ng. CMJ

Jacob Lachapelle is CEO-in-training at Maestro Digital Mining.

Comments