Micromine gives all software mid-year updates

Micromine, next-generation technology for mining, has announced the 2024 half-year release, reinforcing its commitment to innovation and industry leadership. This latest update introduces new features and enhancements across all Micromine products, equipping users with the most advanced tools that are set to significantly boost productivity and efficiency.

Enhancing the platform to encompass the entire mining cycle, here are the key feature highlights tailored for each stage.

For exploration and geology, Micromine Origin geological and exploration software introduces several innovative features in its latest release. The groundbreaking Auto Section Creator automates the placement and creation of section lines, optimizing their orientation and positioning to suit any drillhole configuration. The Surface Map Modeler offers a sophisticated way to transform surface mapping data into detailed 3D geology models, freeing up vital analysis/planning time for Geologists.

With geoscience data logging and management software, Micromine Geobank users can now enjoy a significant enhancement to the field teams tool through the Sample Planner feature. This feature empowers field teams with greater control over field logging, automating sample data entry based on pre-determined sampling procedures. It ensures sample QAQC through seamless implementation of data logging procedures, reducing the likelihood of errors and dramatically cutting the time dedicated to logging sample data.

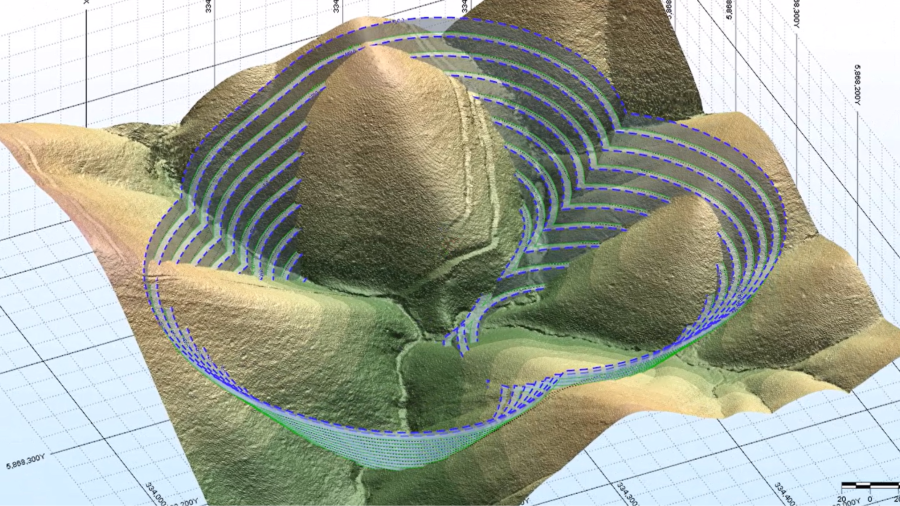

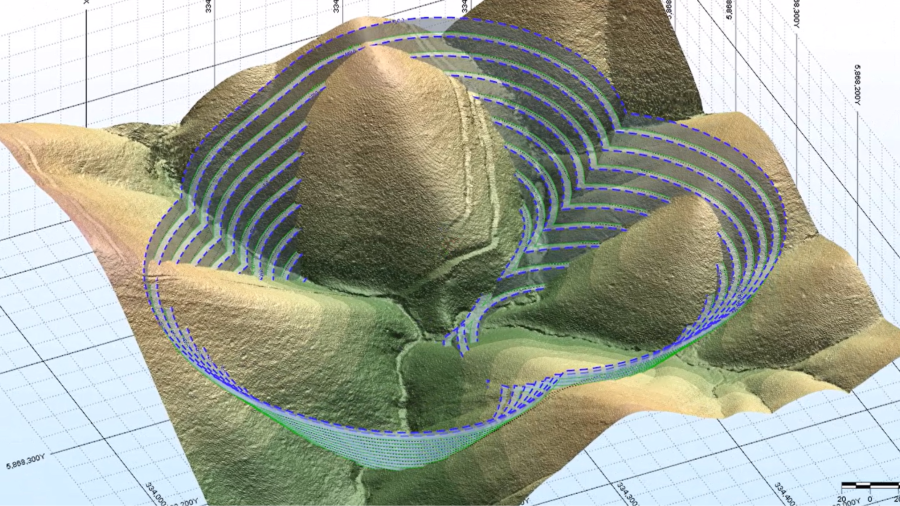

For planning and scheduling, an innovative approach to pit design allows mine planners to iterate between designs and test new ideas quickly. The new toolset in mine design’s Micromine Beyond facilitates an interactive experience that dynamically responds to user inputs in real time, allowing planners to arrive at their optimal pit designs faster.

New functionality in Micromine Spry for soft rock mine planning enables the mine rehabilitation process, by comparing surveyed surfaces from an open pit with a desired future state. The software then produces solids that can be used for the scheduling process. This unique ability assists with reclamation projects and makes the path to mine rehabilitation more finite.

Battery-electric haulage modelling in metals mine planning Micromine Alastri’s Tactical Scheduler has been upgraded to help further quantify the impact of sustainable haulage. An improved methodology to model charger utilization allows mine planners to assess their charger network and accurately forecast energy requirements over time.

For operators, Micromine Pitram an OEM-agnostic mine production, control, and fleet management solution, now offers enhanced integration with third-party services for improved material tracking and system reliability monitoring. Additionally, new role-based access functionality prevents unauthorized changes and reduces potential risks. Users can now also pinpoint deviations and work to stay on plan, boosting efficiency and productivity.

For data management, the cloud-native collaboration and data-sharing solution Micromine Nexus introduces Shared Formsets to facilitate the easy sharing of standardised form settings across teams and projects. This ensures all team members can view and interact with their data in the same way, supporting consistent, visible, and auditable modeling processes.

In summary of the half-year release, CEO Andrew Birch stated, “Our ongoing efforts to advance technology are aimed at transforming the industry and empowering our users to tackle complex challenges effortlessly. Looking ahead, we are committed to attentively hearing our users’ insights, integrating their feedback, and persistently innovating to provide the forefront of mining technology.”

Micromine 2024 half-year release is now available for download and upgrade for all existing Micromine users.

For more information or to request a trial, visit www.Micromine.com.

Comments