Using automation to correct conveyor belt mis-tracking

The friction heat from a mis-tracking belt that comes in contact with a conveyor structure can pose an extreme danger in any dusty environment, not just coal. The U.S. Mining Safety and Health Administration (MSHA) attributes approximately 30% of belt fires to friction caused by critical mis-tracking or belt slippage. Mis-tracking can happen so quickly, often a 24-hour inspection cycle is not enough to catch it and correct the belt path by adjusting idlers. Automated tracking devices monitor minor variations in the belt path and make immediate adjustments to avoid belt stoppage and unscheduled downtime.

With so many factors contributing to belt mis-tracking, achieving perfectly centered alignment may not be possible for most conveyor systems. Everything from ambient temperature to changes in material grade can impact belt alignment causing spillage and belt damage. But mis-tracking is as much a safety issue as it is an efficiency and spillage issue, so monitoring belt drift to avoid contact with the structure is critical.

Current CEMA/ISO standards

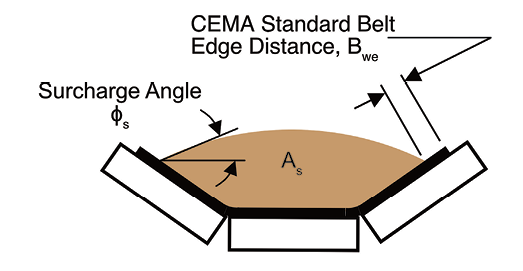

Conveyor Equipment Manufacturers Association’s (CEMA) Guide and the International Organization for Standardization (ISO) Standards 14890 and 15236-1 are very similar in their recommendations for normal belt deviation from the central path. The CEMA Guide is based on standard CEMA components and the ISO standards on the conveyor belt construction tolerances such as camber and troughability.

According to the ISO allowance, the conveyor belting, when running on a correctly aligned conveyor with centered loading, should not deviate from the central track by more than ±40 mm for a belt width up ≤800 mm, or by more than ±5% of the belt width for widths over >800 mm with a maximum of ±75 mm.

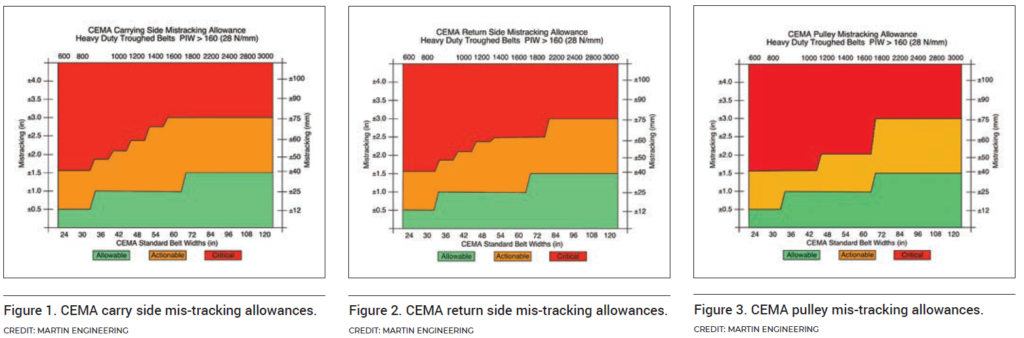

There are three categories into which mis-tracking can be graded: Allowable mis-tracking is the amount of design mis-tracking under normal conditions. Some deviation from perfect tracking is bound to happen on any system due to many operational and environmental factors.

> Actionable mis-tracking happens when operational or environmental factors influence belt tracking to the point where spillage or damage to the belt and/or structure occurs.

> Critical mis-tracking is a second-level fault that creates an immediate and serious risk of substantial damage and injury to personnel. Critical mis-tracking must be corrected immediately to avoid additional spillage, belt or structural damage and other safety incidents.

Consistent belt tracking is a system issue that must be addressed at every stage from specifications to the conveyor’s initial design, installation, operation and maintenance. The project specification should state the mis-tracking allowance as it affects the selection of the belting, structural clearances, and rotating components.

Conveyor installation and retrofits

Installation of the conveyor structure and alignment of the rotating components is the foundation of a system designed to track properly. Often when replacing a belt, components are moved out of the way and not reset in the proper position. Mixing idler brands to save a few dollars or in search of the “perfect” idler can affect belt-to-idler contact and loading point spillage.

CEMA installation tolerances should be followed in the fabrication, erection and mounting of the rotating components. Benchmarks should be established, especially for the main pulleys, so in the event of chronic mis-tracking, there is a reference for confirming the main pulleys are level and square as a starting point for correcting mis-tracking.

The same is true for resetting the idlers square to the centerline as they are often haphazardly knocked and shimmed in an attempt to treat symptoms rather than root causes of mis-tracking. There is a long-standing belief that the belt always tracks to the side of the idler or pulley that it contacts first, so many operators will adjust an idler by pivoting it slightly to move the belt tavel as a corrective action. However, when rolling components are misaligned both horizontally and from level, common corrective actions do not always apply.

When the components are misaligned both horizontally and vertically, the belt tries to flex and contact the component at both edges at the same time. Depending on the direction of travel, an out of level component creates a right hand (RH) or left hand (LH) screw thread effect and the belt may not respond intuitively depending upon which misalignment force dominates, making troubleshooting difficult.

Over time, several corrective actions along a system might cause the belt to develop a memory, making aligning a replacement belt difficult. Excessive adjustments of idlers to treat mis-tracking symptoms increases power consumption and bottom cover wear. When installing a new belt, it is best practice to reset the components within alignment tolerances.

ISO provides an overall allowance independent of the conveyor section or components. CEMA members realized that there was more to the question of misalignment than the free belt edge in the load zone and developed mis-tracking guidelines based on CEMA standard components. CEMA establishes mis-tracking allowances at three critical locations of the conveyors: main pulleys, the carrying side and return runs.

Return side mis-tracking is limited by the width of the CEMA 502 standard return rollers (Fig. 2). Usually, the structure for mounting the return rollers is based on the carry idler base dimensions. Serious injuries have resulted from failed brackets causing falling return idlers. Offset brackets are available but just treat the symptoms of mis-tracking rather than the root causes. Wide base carrying idlers can be specified which in turn would require using a return roll of the next wider belt side, but this comes at an additional capital cost.

CEMA pulley misalignment tolerances are based on ANSI/CEMA B105.1 standard pulley face widths (Fig. 3). When greater tracking variance is required, engineered pulleys are an option.

Proper belt loading

Operators and maintenance personnel should be trained on how overloading and off-center loading affects mis-tracking. Belt tracking is primarily through gravity (center loading) and friction (a minimum of 50% belt contact with the idlers). Spillage and carryback must be controlled for consistent tracking as buildup on idlers and pulleys changes the geometry of rolling components and can reduce belt-to-idler friction.

Skirting and mis-tracking allowances

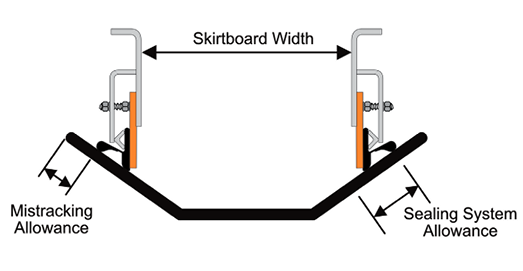

The CEMA Guide started as a best practice for skirtboard sealing systems because spillage in the load zone due to mis-tracking is a common problem. There are many different sealing systems on the market. Depending on the spacing of the skirtboards and the thickness of the sealing system, there could be differences in the amount of free belt edge needed in the design for allowable mis-tracking in the load zone (Fig. 4). If there is a history of actionable or critical mis-tracking that cannot be mitigated, then an even wider free belt edge is warranted.

Modern skirting designs are engineered to minimize spillage by creating a sealed environment within the loading zone. Depending on the type and allowable space of the belt, they can have a double seal that rides the belt offering greater sealing, but that can take up extra space on the belt edge. Skirtboards can lower maintenance costs by self-adjusting as they wear rather than having to be unbolted and adjusted manually when spillage becomes an issue. Once they have worn on one end, some models can be flipped to extend the equipment life.

Automated belt training

Accessories to deal with mis-tracking may come standard with conveyor systems. These are often “brute force” trainers that prevent the belt from coming in contact with the structure and are not actually training systems but merely protective barriers that lead to system issues and belt wear. When the belt drifts, the brute force trainers can cause the belt to fold into itself and fold back into the system. This can permanently damage the belt and lead to further mis-tracking and spillage.

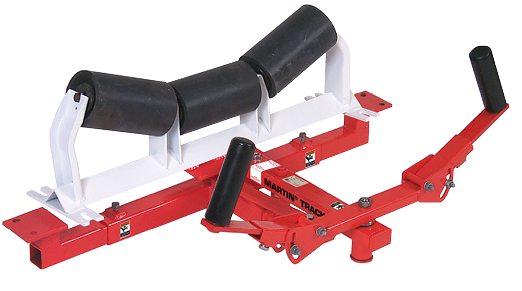

Automated belt trainers use sensing arms to detect slight variations in the belt path. These arms are attached to a pivoting idler that reacts immediately to these variations and trains the belt back into alignment. If detected early enough, less force is needed to retrain the belt and ensure alignment throughout the belt path.

Return trainers act in a very similar fashion but without a troughed roller. Training idlers are set slightly above the belt plane allowing the weight of the belt to offer some additional tension on the roller. As the sensing arm detects the belt drift, it turns the roller in the opposing direction to train the back into alignment. Since the low-tension belt return can easily become misaligned, a return tracker is especially effective when placed near the tail pulley to ensure the belt enters the loading zone aligned.

Design options

The CEMA allowable mis-tracking recommendations do not apply to horizontal curves or specialty belts such as side wall belts. A good starting point for designing for misalignment is to examine current operating and maintenance practices either on site or in the mining industry.

Conveyors bought on 100% loading and price alone often experience tracking issues. Knowledgeable conveyor designers should consult the owner on the significance of design allowances, the costs and benefits associated with wider belts and less than 100% loading best practices. Training operators and maintenance personnel in techniques to reduce mis-tracking is an effective way to mitigate mis-tracking issues.

Laser alignment of components to CEMA installation standards is now a common technique for establishing conveyor alignment benchmarks. Positioning training idlers at critical locations is specified but commonly have limited ability to change the path of the belt when maintenance practices are poor, there are extreme environmental conditions or buildup on the rolling components.

Conclusion

Autonomous belt mis-tracking makes sense from a production, labour, and safety perspective. A belt can mis-track for various reasons at any time, so installing economical equipment to mitigate potential belt fires is a capital investment in both the cost of operation and safety. Over the life of a conveyor, it is cost-effective to contact CEMA member companies for assistance in designing conveyors, specifying components, training, or troubleshooting to identify and prevent the causes of conveyor belt tracking issues.

R. Todd Swinderman is president emeritus of Martin Engineering

Comments