Roundup: BEV makers’ new offerings

A look at recent offerings from OEMs

In this article, CMJ looks at several battery electric vehicles (BEVs) that are new to the market, with capabilities for the mining industry. BEV demand only goes up in the mining sector, and the selection keeps growing.

Epiroc

Epiroc’s “Batteries with Service” is a solution developed to support your operations. A chance for you to own your battery and at the same time get all the service you need when you need it. The service solutions include several benefits to create a sustainable business model — a shortcut to worry-free operations.

You own the battery and are in control of your own equipment. You have got the power. Epiroc offers support when it comes to proper configuration, performance, safety, guidance, upgrades and warranty. The goal is to facilitate an easier transition into battery equipment operations for customers.

Normet

Expanding from powertrain electrification to tools and manipulators, Normet’s SmartDrive battery-electric equipment, introduced in 2019, has gained a global footprint in the mining and tunneling industries. With numerous units deployed globally, SmartDrive has proven its worth in enhancing energy efficiency, performance, and maintenance savings during tens of thousands of work hours with zero local emissions. Building on this success, Normet launched new SmartDrive applications in 2023 for concrete spraying, person lifting, material transportation, and explosives charging.

With BEV technology validated, Normet is broadening its focus to electrifying tools and manipulators. A recent milestone is the launch of Charmec Revo, a remote explosives charger featuring a fully electric, servo robotic arm, available with SmartDrive or diesel carrier options. The robotic arm picks and delivers the initiating system into the borehole and in conjunction with the emulsion kit, dispenses emulsion, keeping the operator in a secure tunnel area, away from danger.

Another example of tools’ electrification is an electric hammer, developed by Lekatech in partnership with Normet. Lekatech’s fully electric hammer offers up to 60% greater efficiency than traditional hydraulic models, delivering significant energy savings and doubled impact force.

Maclean Engineering

The newest addition to the MacLean Elevated Work Platform product suite is a purpose-built alternative to the use of integrated tool carriers (ITs) in underground operations across Australia. The model is designed for mine services installation and repair work from a certified elevated work platform with a 6.5-metre working height and a 4.5-tonne payload.

“Since this first battery electric ML5 Multi-Lift arrived in Australia from our factory in Canada at the end of 2023, we have been testing it and fitting it up at the branch so that it is ready to go to work immediately in Australian underground and surface mines,” remarks Peter Black, technical sales manager at MacLean, based out of the company’s branch in Perth, Western Australia. “Its application versatility is best-in-class, and we are offering it up to the industry with a battery electric drive, so miners

and contractors will get a diesel-free dividend along with the safety and productivity enhancements that we have engineered into the design from the ground up.”

“We are now able to offer a range of mine services installation and repair solutions to mines around the world, depending on their haulage ramp and drift sizes, the size and weight of the infrastructure being installed or repaired, and the working height,” remarks Jari Tuorila, vice-president Australasia. “This is what we mean when we say we have safety in our veins and innovation in our DNA. We engineer solutions for the actual job underground.”

Sandvik

Toro LH518iB marries industry-leading battery-electric and automation technologies. Building on predecessor Sandvik LH518B, Toro LH518iB features several design updates and significantly improved field serviceability. The latest version of Sandvik’s intelligent control system enables AutoMine readiness. Sandvik’s patented self-swapping battery system, including the AutoSwap and AutoConnect functions, benefits from improvements to the operator’s controls to facilitate battery swaps.

Toro LH518iB is automation ready, and the loader can be equipped with Sandvik’s AutoMine system. The 18-tonne loader is equipped with standard valves, harnesses and other built-in hardware for automation. The AutoMine onboard kit will be available as an option, providing scanners, AutoMine box, and wireless connectivity.

With AutoMine, one operator can run the entire cycle from a surface chair, including tele-remote battery swapping. Human involvement underground is only required for connecting and disconnecting batteries from chargers and coolers.

Rokion

The R700 is Rokion’s newest line of industrial support equipment featuring dual end functionality. This multi-purpose platform is built for versatility with a quick attach system that supports a variety of accessories including forklift, backhoe, loader, bolter, blade, tire manipulator, and man lift.

The R700 is designed for optimum performance, even on uneven ground, with a shifted articulation pivot reward to reduce the relative motion of load and keep the center of gravity within the track width of the vehicle. Engineered to handle the harshest mining conditions safely and efficiently, the R700 is outfitted with configurable auxiliary hydraulic power circuits, five efficient induction motors, dual steering cylinders, 180° seat swivel, and on-board charging.

MEDATech BEVGen

What happens when BEVs need extra range? The MEDATech BEVGen is a fully automatic onboard diesel generator that acts as an onboard charger. BEVGen plugs into a vehicle’s BMS via J1939 CAN network connection. Drop below a certain state of charge, and it switches on automatically, precisely delivering the amperage and torque that any machine requires, right up to 540 kW max/430 kW continuous power. Hit a higher state of charge threshold, and it switches off. BEVGen is compact and easy to add to any BEV. It is due to become available in Q2 2024.

Aramine

Eight years after the launch of its first battery-powered mining machine, the L140B, Aramine is marketing its larger L440B loader. Pioneer in this market segment, the French manufacturer is expanding its range with a larger machine to meet its customers’ demand. With a capacity of 4.5 tonne and all the successful solutions of the L140B, such as the QRS Battery quick replacement and the on-board battery charger, the L440B is easy to introduce underground, as it does not require any specific infrastructure or changes in the mine. Only some electrical plugs, 32 Amps, and 4 tonne crane are required to charge the spare energy module while the machine operates with its charged module. Today, L140B and L440B are allowing to transform any underground mine from 6 to 14 m2 sections in zero CO2 emission mines. The effects are quickly visible, not only in the reduction of pollution but also in the temperature in the galleries and avoiding the need to transport fuel underground.

Hitachi

Hitachi Construction Machinery will begin testing a full battery electric vehicle (BEV) prototype version of the Hitachi EH4000AC-3 244-ton (221-tonne) truck. The engineless, full battery rigid frame dump truck was transported to the Kansanshi copper-gold mine in Zambia and will be tested at the mine in mid-2024.

The truck’s energy-efficient DC/DC converters allow it to remain in continuous operation with no charging breaks.

As the truck climbs uphill, the wheel motors are directly powered from the external trolley while also recharging its battery. On ground level, an internal battery powers the truck. During downhill operation, a regenerative braking system recharges the battery.

This truck’s innovative battery technology was created through a collaboration between Hitachi Construction Machinery and ABB Motion’s traction division.

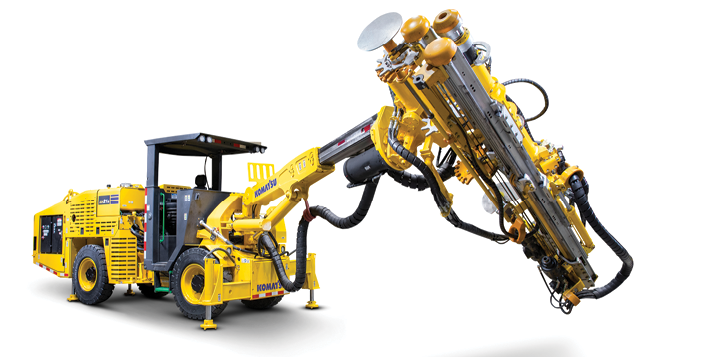

Komatsu

The ZB21B bolter is driven by clean battery power, which supports Komatsu’s customers’ journey to electrification and sustainability. This model features Komatsu’s innovative approach to BEV — both onboard and smart opportunistic charging with 100% compatibility with existing mine infrastructures.

This innovative bolter has a modular battery driveline with 83 kWh of onboard energy for the most demanding tram cycles and challenges of underground mining. Plus, the integrated screen handler allows operators to complete a full bolting cycle inside the cabin. All bolt types are supported. Look for the Komatsu ZB21B bolter at the upcoming CIM Convention and Expo.

Liebherr

The new Liebherr battery-electric truck, T 264 BET 100, is poised to revolutionize mining operations. With its dual compatibility for static and dynamic charging, it seamlessly adapts to diverse site infrastructures. When parked, this truck can utilize static chargers and during the haul cycle, it can integrate with trolley systems for charging on the go. Boasting only a 30-minute charge time, downtime is minimized, enabling maximum productivity. Plus, Liebherr’s modular design enables any T 264 purchased today to be repowered with the OEM’s advanced battery technology in the future.

Liebherr is working in collaboration with Fortescue WAE, a leader in electrification solutions, to ensure the truck delivers both minimal downtime and extended battery life.

RDH Scharf (SMT Scharf)

With the new LEV, SMT Scharf has launched an exceptional vehicle onto the market. It is based on the Toyota Land Cruiser known for its impressive off-road capabilities. However, the LEV goes one step further by replacing the conventional combustion engine with a powerful electric unit and offering unique battery technology.

One of the outstanding features of this vehicle is the safety it offers in hazardous working environments. The individual cells of the battery designed and manufactured by SMT Scharf are surrounded by a dielectric fluid. In the very unlikely event of a defective cell resulting in fire, the dielectric insulates the fire, absorbs the heat, and thus prevents other cells from igniting.

All in all, the Scharf LEV is a pioneering electric vehicle that not only protects the environment, but also increases safety and efficiency in demanding working environments.

Comments