JV Article: FM Global: De-risking the mining industry’s onsite energy infrastructure transitions

The mining industry is in a race to meet decarbonization goals and facing investor pressure to improve ESG metrics and bring operations in line with green energy transition objectives.

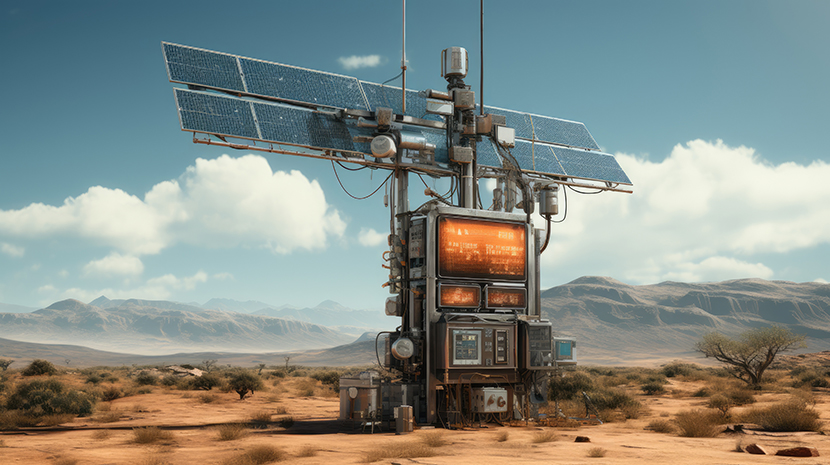

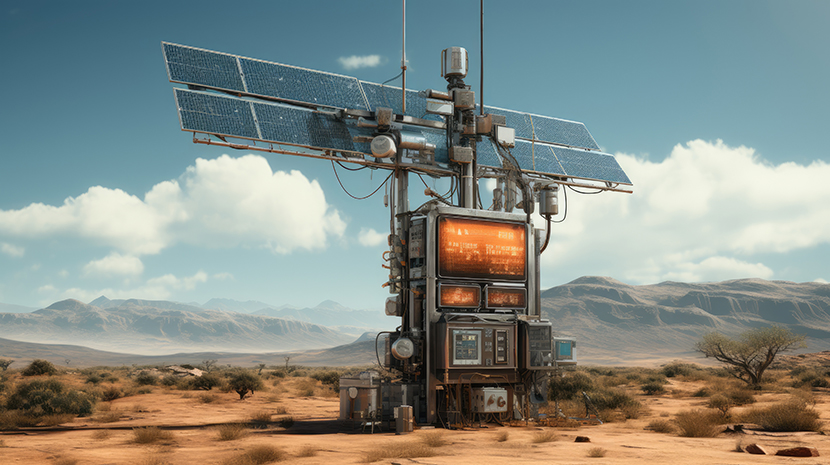

Achieving these goals means a shift to renewables, which requires new infrastructure. Moreover, the quest to electrify operations brings with it new risks for miners to mitigate.

FM Global, a major global insurer with over 50 years of experience in the sector, understands the often-unseen hazards in mining operations and how to implement contingency plans.

Neil Chaudhuri, chief engineer for FM Global’s Canada operations, says the company’s proven loss prevention expertise and suite of analytics capabilities build resilience into mining operations by harnessing the power of thousands of data points from engineering onsite visits around the world.

“Along with our FM Global Property Loss Prevention Data Sheets, we can leverage our research and chief engineers’ group to provide technical guidance to help facilitate and help create more customized solutions to solve some of the more complicated technical risks that we see at our client sites,” Chaudhuri says.

“One of our key differentiators is our engineering and research. All our underwriting is based on engineering risk assessments and is underpinned by data.”

FM Global’s specially trained field engineers physically go to sites to assess hazards and risks that can lead to a loss, such as fire and natural hazards or boiler and machinery hazards. Field engineers use the FM Global Property Loss Prevention Data Sheets and also stay current on how to protect from emerging risks, such as fire from electrification and lithium ion battery energy storage systems, and make recommendations.

FM Global is driving research in this area to better understand emerging risks for clients embracing these new technologies. Key considerations include fire protection measures, construction location in proximity to critical buildings, emergency response planning and appropriate fire response equipment.

The company has a research campus which does large scale fire testing, natural hazard research for floods, earthquake, wind, boiler and machinery, as well as electrical hazard research.

FM Approvals, also located at the research campus, runs facilities and laboratories that offer third-party testing and certification services on property loss prevention products and services.

FM Global Property Loss Prevention Data Sheets are used to assist in the underwriting of coverage at the locations and accounts based on the exposures found on site.

The reports also contain risk improvement recommendations that will help the client understand the risk and determine what they can do to address the recommendations to mitigate any losses from such risks.

While the industry has historically depended on diesel to provide power and fuel for haul trucks, the push for electrification can bring new hazards, such as risk of a grid power failure. The path to electrification inevitably leads to more electrical infrastructure. Risks surrounding this additional infrastructure need to be considered.

Weather phenomena like hail can damage renewable energy infrastructure and damage solar panels, or heavy rains can potentially cause flooding of hydroelectric stations, Chaudhuri points out.

Thermal runaway is a big risk in lithium-ion battery energy source systems, which can be initiated by thermal abuse like overheating and overcharging or mechanical and operational abuse. Moreover, sprinkler protection for indoor units or adequate space separation of outdoor units from critical buildings is paramount to mitigating loss.

Other concerns with the shift to renewables and electrification, Chaudhuri notes, include the potential for cyber-attacks, which can shut down a system entirely.

“Electrical equipment and autonomous haul trucks are also vulnerable to cyber-attacks – and could be potential blind spots. Part of our service is assessing cyber hazards on industrial control systems and making recommendations to mitigate these hazards,” Chaudhuri says.

“New emerging technologies and risks that we see in the field are shared with our chief engineers group so we stay ahead and can come up with risk improvement solutions to address hazards. The sooner we get involved on projects to test for and identify risks, the better.

Then we can work on the design phase of a project all the way to the construction phase, which enables our clients to implement our loss prevention advice at the outset, ensuring their facilities are highly protected from risk.”

The preceding Joint Venture Article is PROMOTED CONTENT sponsored by FM Global and produced in co-operation with Mining.com. Visit: www.FMGlobal.com for more information.

Comments