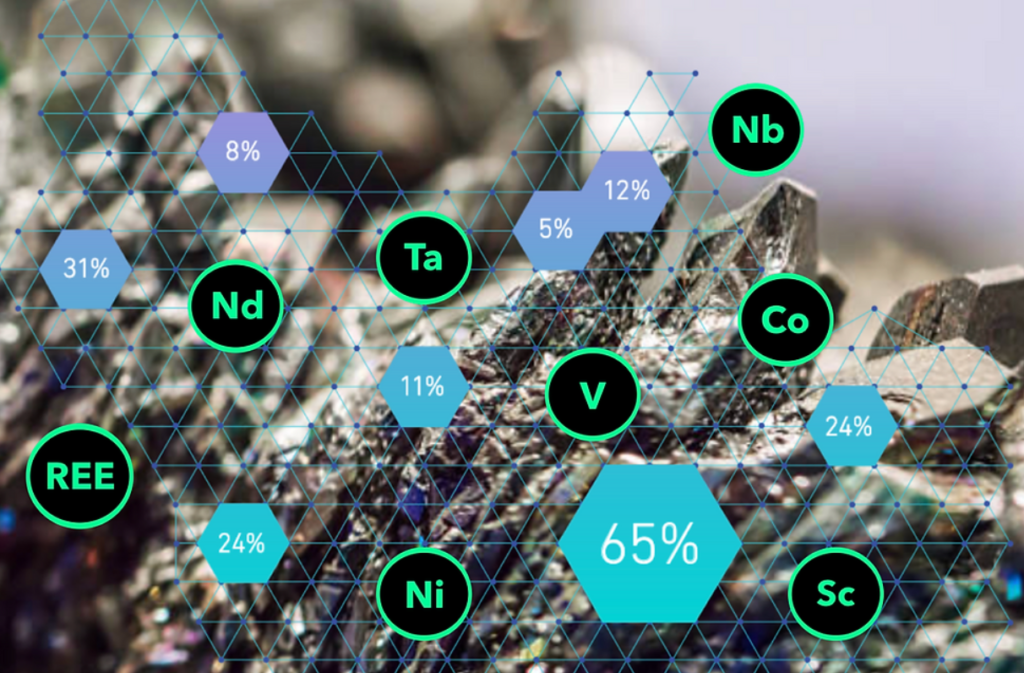

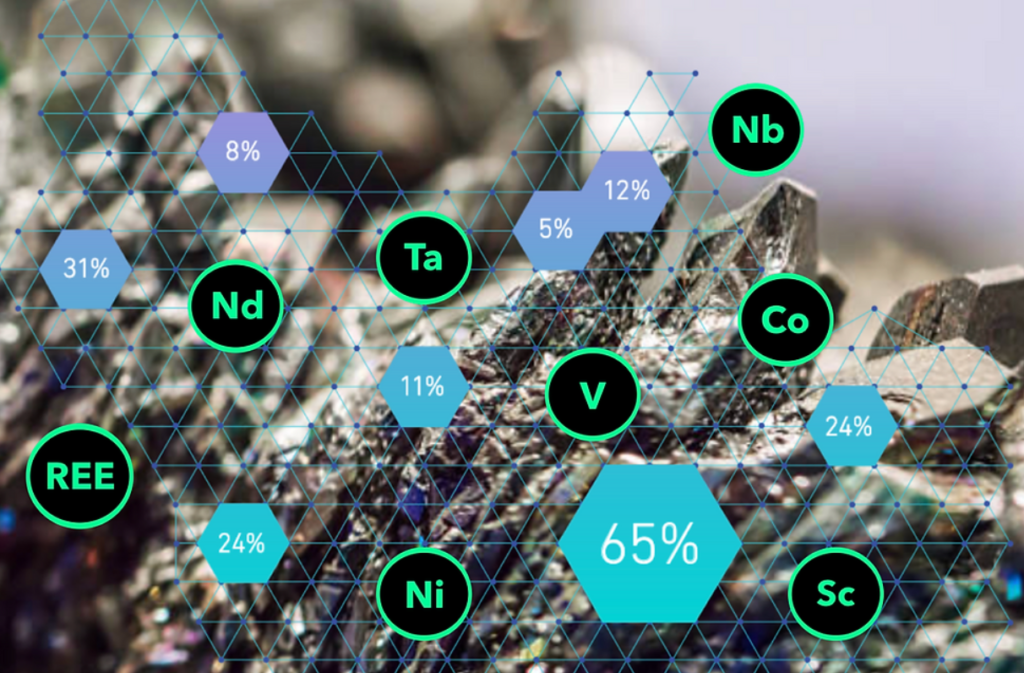

Central America Nickel files patent for extracting rare earth elements

Central America Nickel (CAN) has filed an international patent application titled “Process for Extraction of Rare Earth Elements.” The technology creates light and heavy commercial rare earths concentrates using one or more leaching steps and CAN’s ultrasound assisted extraction (UAEx) as a process intensifier.

The company believes that using UAEx technology will significantly reduce both the capital and operating costs of producing these concentrates. Results indicate that when leveraging this proprietary metallurgical process of acid leach enhanced by both ultrasound and calcination at various stages, commercial concentrates at grades up to 46.9% neodymium, 14% praseodymium, 16.1% dysprosium, and 3.4% terbium can be produced.

UAEx is also recognized as an environmentally friendly alternative to conventional processing. Not only are recoveries increased, but processing time is also reduced.

CAN conducted its tests on samples from Auxico Resources Canada’s Mynastyc project in Vichada, Colombia. Both companies aim to refine critical minerals into end user forms for the EV battery and powertrain components manufacturing supply industry and have jointly conducted scoping studies for the developing of processing and refining facilities alongside technology partners including Impact Global Solutions, Coalia, Polytechnique Montréal, and McGill University.

A patent application for the same technology has been filed in the Democratic Republic of Congo.

Learn more about UAEx on www.CentralAmericaNickelUAEx.com.

Comments