Metso now offers complete battery minerals production and recycling

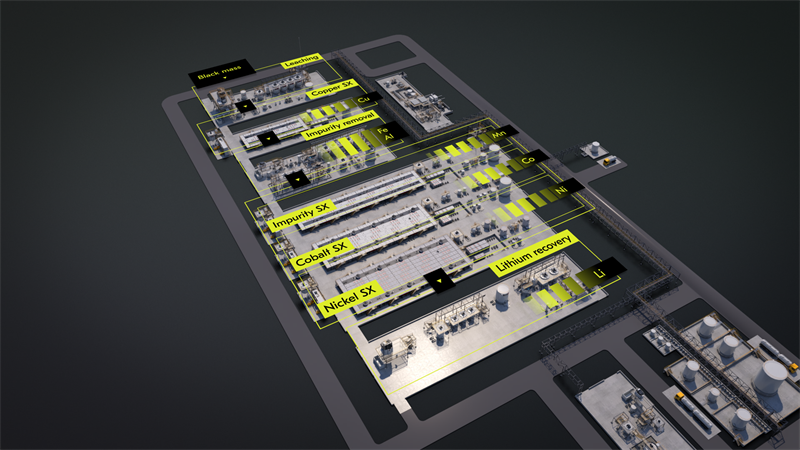

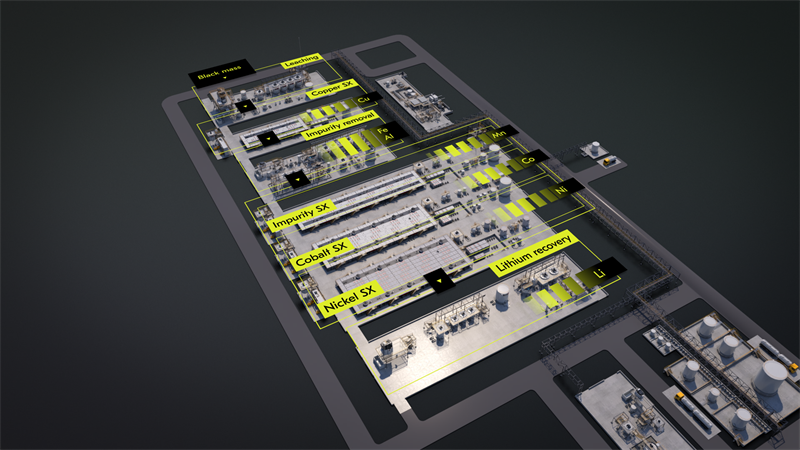

Metso has strengthened its position as the preferred technology and solutions provider for the battery minerals industry with the recent launch of the battery black mass recycling process.

Metso now offers complete processes and services for battery minerals production – from minerals extraction to refined battery chemicals and end-of-life battery black mass recycling.

Metso’s recycling process offers complete processes for lithium extraction from brines or ore.

For the hard-rock based spodumene concentrates, Metso has developed an acid- and sulphate-free soda pressure-leaching process. According to the company, it is one of the most environmentally sustainable processes available for lithium production.

“Our strength in battery minerals process design is based on the deep concentrator and hydrometallurgical knowledge we have gained through working with our mining customers around the world,” stated Don Simola, director of Metso’s battery chemicals business.

“The battery market is very active, and we are currently working with several lithium processing and battery recycling projects that are in the study, piloting, engineering or delivery phases.”

Read more about Metso’s offering for battery minerals on www.Metso.com

Comments