Sandwich belt high angle conveyors are in harmony with the environment

Sandwich belt conveyors are utilized by several industries. Even before the increased awareness for environmental compliance, sandwich belt conveyors provided the following benefits with their natural capabilities:

> Conformity to landscape: Conformity to irregular (steep) paths to blend in with the surrounding environment. This feature precludes the need for many transfer points which are a common source of spillage and fugitive dust.

> Compact arrangements: By virtue of their high capacity, high angle and adaptable profile features, sandwich conveyors facilitate the most compact arrangements of any materials handling system, thus minimizing disturbances of the environment.

> Minimizing excavation disturbance of the sub-surface: Sandwich belt conveyors allow the most direct haulage path from deep open pit mines and from underground excavation projects eliminating the cost of any additional excavation.

> Reduction in real estate and spatial volume: In plants, they use the least real estate and in 3D space, displacing the least spatial volume. Because sandwich conveyors can be housed in a facility, they will require the least amount of wall and roof surface. For heated facilities in cold climates, they offer the least heat escape, thus the lowest heating cost.

> Creating a power source: A downhill sandwich conveyor system can operate regeneratively, thereby feeding power to the grid, becoming a power source.

Industries that have benefited from these advantages include sludge and sawdust handling in composting systems, biomass for fuel in the form of RDF (refuse derived fuel to garbage) to power projects, hog fuel at pulp and paper mills, and shredded tires for fuel at cement plants, to name a few.

Conformity to the landscape

Sandwich belt high angle conveyors’ ability to conform to the irregular profile of the landscape was proven at a Virginia mine in the U.S. Coal refuse was being hauled from the prep plant to the dump site along a steep mountain path by two aerial tramways. They traveled conspicuously above the mountain slopes and created a black streak of spillage under their respective travel paths. Steep curving ramps for trucking scarred the landscape, while the trucks polluted the air with fumes, particulates, and noise and created the potential for disaster from traffic accidents.

The sandwich conveyor eliminated these problems while offering a conveying capacity higher than the previous combined system. High angle, as well as conventional conveyors, were considered for this application; however, conventional conveyors required considerable elevated structure, were obtrusive on the landscape, and with the several additional transfer points, created a potential source of spillage and additional expense.

Compact arrangements

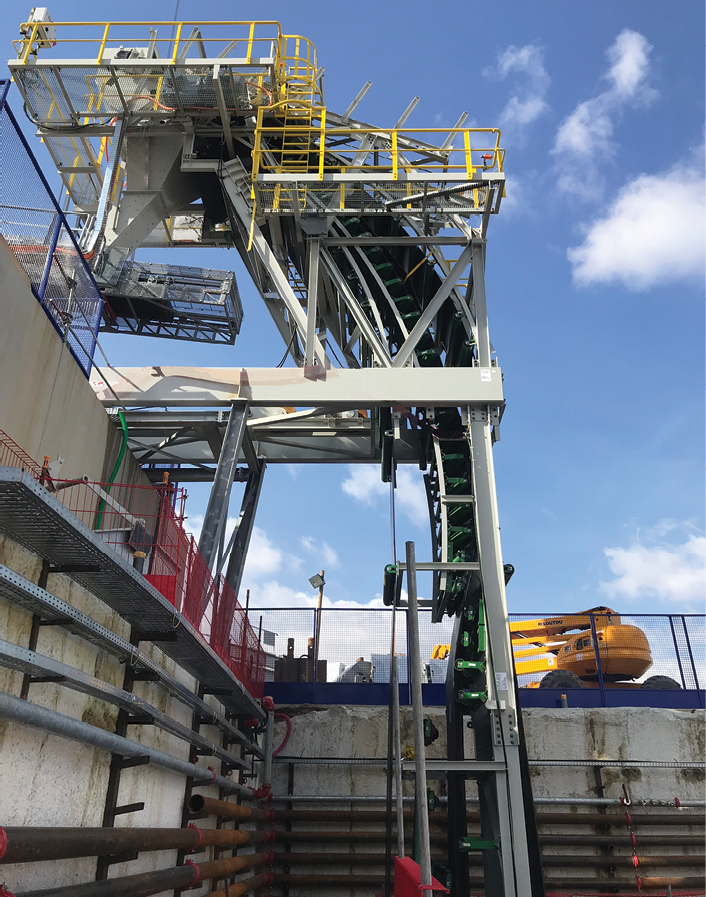

In some cases, sandwich belt high angle conveyors have facilitated materials transfers in very tight spaces at existing sites, while in others they have opened the door for the most compact new materials handling systems. A vertical Dos Santos International (DSI) GPS sandwich conveyor for the Paris Metro tunneling project elevated sticky tunnel muck at a design rate of 800 t/h. This was done without disturbing vehicular or pedestrian traffic.

The challenge of this project was providing a versatile system that will be reused in future projects. Accordingly, DSI designed a system with a high degree of versatility – particularly extendability. With all the drive and take up equipment located at the head end, DSI designed the vertical portion as a hanging structure which can be extended as necessary for higher lifts at future applications. The two sandwich conveyors at the two sites in Paris are nearly identical, with only a small difference in the length of the vertical portion. DSI designed both conveyors for the possibility of increasing the lift to 45 metres. The two conveyors in Paris have vertical lifts of 24.6 metres and 26.3 metres, respectively, and can be used for any intermediate height up to 45 metres. This makes them very versatile for use at future sites.

Minimizing excavation disturbance of the sub-surface

Sandwich belt conveyors allow the most direct haulage path from deep open pit mines and from underground excavation projects. A high capacity, high lift system can most certainly handle the severe haulage requirements.

Once such system conveyed hard primary crushed rock (-250 mm) along the steep mine wall, directly out of the pit. This reduced the truck haulage requirements of that mine, displacing 10, large, 240-tonne trucks from the severest of haulage duties (the slow, high power, continuous climb to the surface).

As important as it is to eliminate the associated pollution and accident potential, minimizing total excavation for the ore recovered is also important. The sandwich belt system requires no additional excavation. Conventional conveyors, though equally efficient to the sandwich belt conveyor, require additional excavation and/or additional transfer points because of the limited slope capability.

Reduction in real estate and spatial volume

The challenge to use the least amount of space possible to process and separate kimberlite at Canadian diamond mines was the motivation for the installation of DSI sandwich belt high angle conveyors.

The first project was in the Northwest Territories at Snap Lake. The orebody was a dyke that dipped an average of 12-15° from the northwest shore down under the lake. Kimberlite was brought to the surface to a processing facility where the diamonds were extracted. Because of the hostile environment, the facilities had to be enclosed and heated. A smaller footprint for the plant was determined to be the optimal way to minimize environmental impact and cost.

The original concept was to use many sandwich conveyors to minimize the facilities. This was rationalized to require only two sandwich conveyors, which defined the facility’s minimal footprint. The ability to convey at any high angle, along with the sandwich belt imparting a gentle, yet firm hugging pressure on the material, allowed the precious gems within the kimberlite to be elevated at high angles without damage or spillage. The Snap Lake project incorporated two DSI sandwich conveyors, each traveling to opposite ends of the building. The units were standardized at 90 cm belt width to simplify spare parts inventory. The design of the units included provision for future upgrade, from 275 t/h to 524 t/h, merely by increasing the belt speed. By operating at the lower speed until the upgrade is required by the sandwich conveyors, optimal energy efficiency is preserved.

Creating a power source

A downhill sandwich conveyor at a Venezuelan phosphate mine combined the duties of a gathering conveyor from beneath the storage pile and an overland conveyor. This eliminated transfers and much elevated structure. An added feature to this system was that as a regenerative lowering system; it produced electricity to become a power source.

Other industries that benefit

The versatility of sandwich belt conveyors allows for endless profiles that are adaptable to many widely varying configurations, especially beneficial for environmentally friendly projects.

At composting systems, city sludge is mixed with sawdust and composted into a useful material, a soil additive. In biomass to fuel and RDF, garbage to power, a sandwich belt conveyor replaced four pocket belts that were in place at a plant in Florida.

In Maine, at a pulp and paper mill, the refuse bark and rejected chips went to a boiler to serve as fuel. This would otherwise be wasted materials.

Finally, DSI designed a hybrid sandwich belt high angle conveyor to efficiently transport shredded tires at a cement plant to create an alternative fuel source for cement production. Instead of disposing of the rejected tires, they now serve as a power source for the cement plant.

Amy Duncan has been the marketing manager for Dos Santos International since 2007; however, she has been exposed to the Dos Santos sandwich belt high angle conveyor technology since the 1980s.

Comments