Quebec’s Nouveau Monde, a Canadian model for vertical integration and sustainability

An interview with Eric Desaulniers, founder, president, and CEO of Nouveau Monde Graphite

Nouveau Monde Graphite (NMG) is striving to become a key contributor to the sustainable energy revolution. The company is developing a fully integrated source of carbon-neutral battery anode material in Quebec for the growing lithium-ion and fuel cell markets. With low-cost operations and rigorous ESG standards, NMG is on its way to become a strategic supplier to the world’s leading battery and automobile manufacturers, providing high-performing and reliable advanced materials while promoting sustainability and supply chain traceability.

NMG’s turnkey natural graphite operation has competitive advantages because of its convenient location, vertical integration, cost structure, ESG credentials, and experienced team.

The company’s phase-2 Matawinie mine and Bécancour battery material plant projects, located within a 150-km radius of Montreal, show attractive economics and robust operational parameters underpinned by a large mineral property, NMG’s proprietary technologies, and clean hydroelectricity powering its operations.

Vertical integration is a strategy that allows a company to streamline its operations by taking direct ownership of various stages of its production process rather than relying on external contractors or suppliers. Recently, I caught up with Eric Desaulniers, founder, president, and CEO of NMG to get insight into the company’s strategy for vertical integration and how NMG plans to become a Canadian model for sustainability.

CMJ: To start our conversation, can you please talk briefly about your journey to become the CEO of NMG?

ED: I am a geophysicist by training, so I am a geologist who did not like geology. I first started working after my master’s degree in 2006, for a large airborne geophysical company in Ottawa, called Sander Geophysics, from 2006 to 2011. In 2009, I also started my geophysical airborne company doing airborne surveys measuring the connectivity of the ground. In 2011, I stopped working for Sander Geophysics to focus on my company. The idea was to explore untapped territories using a new technology. My partner was the owner of the helicopter, and I was taking care of all the data processing. Then, I became CEO by incorporating the company, and it started from there.

CMJ: You only began exploring in 2012, correct? What was the earlier history of the project? Was it a new exploration?

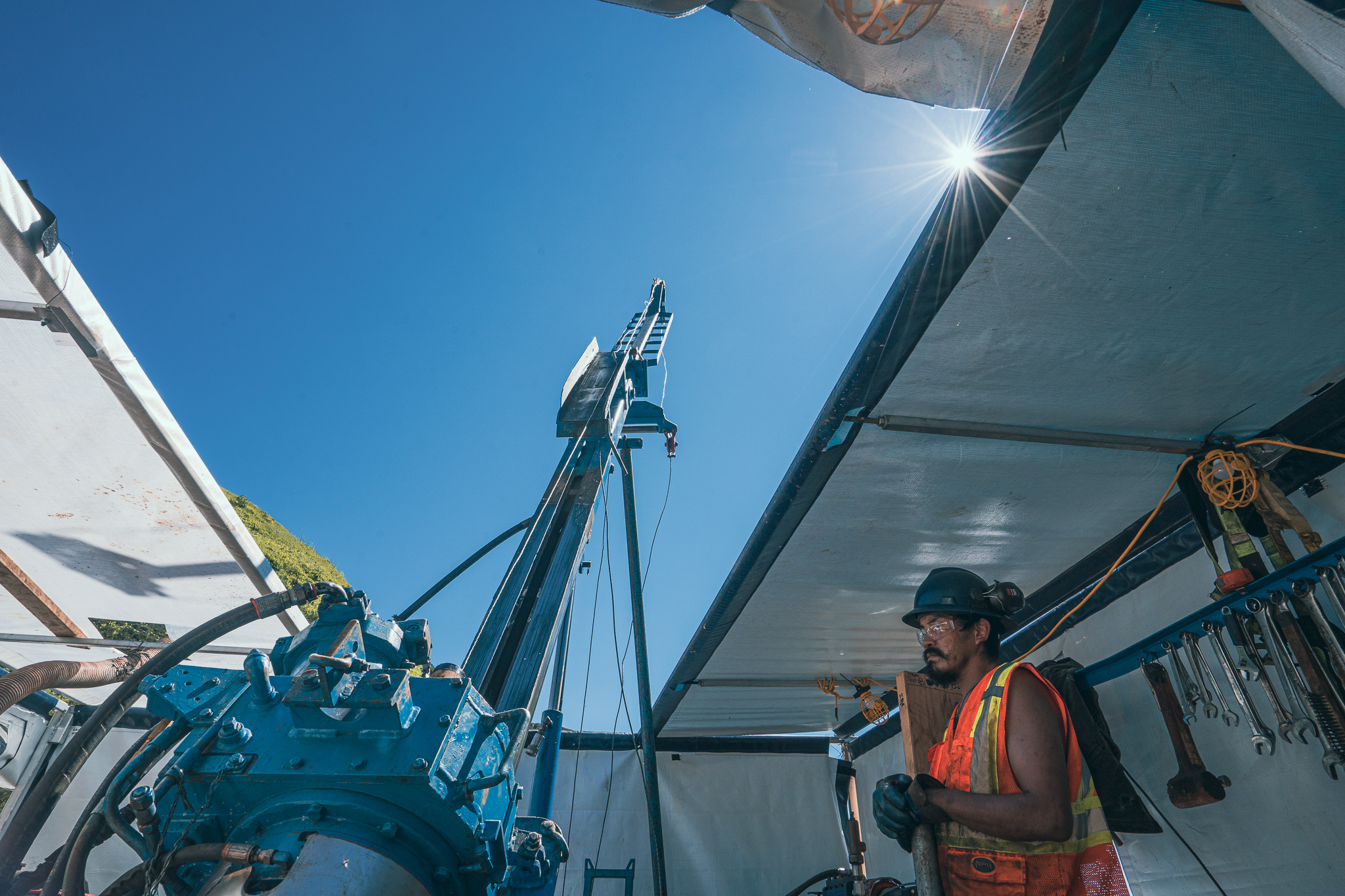

ED: Yes, correct, and it is a new exploration. There was no history of exploration in the same area where we discovered the deposit. The idea was to explore with airborne geophysics a very large territory, and we were doing a line every one kilometer. We covered thousands of square kilometers of untapped territories to directly detect conductors with the system. When there was a conductive material in the ground, we sent our geologists to do the hard work from 2012 to 2015. we drilled a little bit (over 20 different anomalies) until we made this discovery in 2015.

CMJ: Environmental hurdles and navigating bureaucracy have made it challenging to manufacture batteries in Canada. However, Quebec released the Plan for the Development of Critical and Strategic Minerals in 2020 to move rapidly to support the right development proposals and has earmarked billions for that purpose. The federal government claims to favour a “partnership orientation.” What was your experience with both levels of government?

ED: Both levels of government were very supportive. The Quebec government is our second largest shareholder, so they have a financial commitment to the project, which is very helpful. Although the permitting process is still bureaucratic, the authorization of the Matawinie graphite mine by the Quebec government following a rigorous environmental review and public consultation was still a very good process compared to the rest of Canada.

Overall, it went very well on the Quebec side and the permitting process was relatively smooth. And the next important step is the commitment from the government to the supply chain. The minister of economy is very knowledgeable of all the supply chains; he is meeting with potential customers in Europe and Asia to understand how to position Quebec into this market. Having that mindset at the top level is very important. The federal government was also very helpful. We started up by financial support from the federal government’s R&D financing. The federal government of Canada has supported two of our projects to commercialize the technology.

Now, we are negotiating with Export Development Canada (EDC) to finance our commercial project and exploring opportunities with the government’s Strategic Innovation Fund that focuses on the green economy and decarbonization.

This is a good way to demonstrate that the federal government can be helpful from the conceiving of the idea all the way to commercializing and building the large-scale project. Obviously, building a supply chain for battery metals is a new concept for everybody, but there are different programs that support us along that journey. Both governments are doing their best to make it happen, which is very good.

CMJ: Can we say that you are leading the way for this technology in Canada, and you will be the model for anyone doing the same kind of business on batteries in the future?

ED: Yes, we are the most advanced battery material project in Canada. We are building a business model around our vision for a cleaner future. We went all the way from being a penny stock exploration, grassroot project that made a discovery to making the transformation plant. We invested over $75 million in the transformation plant. Now, we are very close to the full project financing and building the plant.

CMJ: NMG is developing a turnkey natural graphite operation with competitive advantages due to its key location, vertical integration, cost structure, ESG credentials, and experienced team. Can you please explain how NMG is adopting a route to sustainability by offsetting the potential impact on the environment? How are you going to adopt an all-electric operation in the manufacturing and mining facilities?

ED: Mining is an energy-intensive industry, and this is a key topic for our competitiveness. It is really the fact we can build the full vertical in a very short radius. Other jurisdictions have great graphite deposit, namely in Southern Africa, Brazil, China, and India, but you cannot find both together at the same place other than here.

We have everything within a radius of 150 km; we have a great graphite deposit with the best you can dream in terms of location and size of the deposit. You can have a very attractive mining project, but to transform the product all the way to the final material needed by using the infrastructure in place, affordable and clean hydropower, all the chemical reagents needed, and skilled labour. We are also fortunate to have several universities, so we can recruit PhD and experienced engineers. It is our job to commercialize at a large scale, which is not something that we were asked to do in the past when all batteries were made in Asia. NMG is projected to be North America’s largest and only fully vertically integrated natural graphite operation, favourably positioned to provide a localized and carbon-neutral alternative to Chinese supply for the Western World’s battery and automobile manufacturers. Having all the components needed is something unique to Canada.

ESG is in our DNA, in 2021, our team gathered for a special two-day event dedicated to ESG. Under the theme of sustainable development, we talked about our business strategy, self-achievement, ESG concepts, and the history of First Nations.

The clean energy revolution is accelerating. For the transition to clean energy to be sustainable, the world needs ESG-minded investments to develop clean energy solutions. For NMG, it is a clear differentiator from what our competitors in China are doing.

At NMG, we set our minds on sustainability from the onset, and we acknowledged the responsibility of developing a non-renewable resource. We recognized the immense opportunity of having access to abundant, affordable, and clean hydropower. In 2017, we committed to building the world’s first all-electric fleet for an open pit mine. In June 2021, we signed an agreement with Caterpillar for the development, testing, and production of Cat “zero-emission machines” for our Matawinie graphite mine. This future fleet will be supported by a dedicated hydroelectricity power line.

When fully operational, our fleet should result in approximately 85% less direct GHG emissions from our mining operations.

Combined with our ecotechnologies for value-added transformation of our graphite concentrate, the adoption of all-electric operations enables us to bring to market anode material with a 50x-smaller greenhouse gas footprint than common spherical graphite and 14x-smaller carbon footprint over the product lifecycle compared to the Chinese supplier of natural graphite. Hurdles to implement do exist, but they should not stand in the way of modernizing mining fleets. Going electric means significant upfront costs but also considerable operational cost savings and environmental and social benefits down the road.

CMJ: Since you have a vertical integrated operation, can you give us an idea on the Bécancour battery material plant? Do you have existing off-take agreements? Are you in the future thinking of other investments?

ED: For graphite to be used as anode material, three beneficiation steps are required to reach the optimal properties and performance: shaping, purification, and coating. NMG plans to leverage its access to the large, high-purity Matawinie graphite deposit as feedstock for its value-added transformation activities, hence capitalizing on operational efficiency, product traceability, and greater margins from its vertically integrated business model. Our proposed advanced manufacturing operations is in Bécancour, Que., approximately 150 km northeast of Montreal, by the St Lawrence River. The robust local infrastructure provides us with direct supply of required chemicals in addition to affordable hydroelectricity, skilled workforce, and a multi-modal logistical base that includes a major international port in proximity to U.S. and European markets.

Continued commercial engagement with potential tier-1 customers in the EV and battery sector supported by production at NMG’s phase-1 operations and participation to key forums dedicated to advanced battery technology. Admission to the Global Battery Alliance, a World Economic Forum’s initiative regrouping leading players of the industry for helping establish a circular and sustainable battery value chain.

In 2021, we made considerable progress with respect to the battery material plant project. Our shaping unit continued to produce spherical graphite to support qualification with potential customers and further testing to optimize our processes. Successful results in this regard have led us to purchase another commercial-scale module, hence tripling our production capability. In 2020, we announced a five-year agreement with Olin Corporation which covers the manufacturing space for our phase-1 purification operations, site services, and the supply of certain raw materials to support the commercialization of our advanced graphite materials. NMG’s first two commercial-scale purification modules were successfully constructed and commissioned this year within existing space at Olin’s Bécancour, Que., facility.

Europe constitutes a prime market for the battery segment due to its booming EV industry, strict environmental regulations, and infrastructure development programs supporting electrification. With commercial discussions intensifying with European automakers for NMG’s battery anode material, we opened a London-based sales office in 2020 to readily respond to the growing enquiries from local customers and stakeholders. Samples have been and continue to be provided to potential customers as part of sales discussions.

In addition, we have already entered into a binding off-take and joint marketing agreement with Traxys for flake graphite concentrate from the Matawinie graphite mine. Traxys markets flake graphite concentrates from our phase-1 operation for customer product prequalification purposes. Traxys will have the exclusive right to market, distribute, and resell the flake graphite products to its customer base.

We achieved critical milestones in developing our vertical strategy through the advancement of our phase-1 facilities, the permitting and engineering of our phase-2 operations, the commencement of early construction work at our Matawinie mine, our commercial discussions with tier-1 battery and EV manufacturers, our listing on the world’s largest stock exchange, and strategic financing rounds. Strong in our integrated value chain, our technical marketing team, the production of hundreds of tonnes of samples – in a variety of specs – and the desirable environmental footprint of our product portfolio, we are positioning NMG at the forefront of the Western World’s natural graphite anode material production. Finally, last July, we announced the initial closing of the previously announced investment agreement between NMG and Mason Graphite to explore the development and operation of Mason Graphite’s Lac Guéret property in Quebec.

The agreement provides an opportunity to NMG and Mason Graphite to form a joint venture, where Mason Graphite would grant an option to NMG to acquire a 51% interest in the mine and its related assets.

CMJ: You participated on our panel discussion during PDAC 2022, that highlighted the lack of the right skills and labour shortages in the battery production sector among other aggravating factors such as slow-moving regulatory bodies and economic climate. How do you plan to deal with the skilled labour shortage in the battery manufacturing?

ED: My main point in the discussion was to make sure everybody understands that we are not making only one revolution, but two revolutions at the same time. The first is making everything electric, which triggers new construction projects with investments needed to finance those projects. The second revolution is the decision to manufacture everything in Canada. We do not want to rely on Asia and the 1.2 billion people in China.

The 38 million people in Canada need to make it happen. I hope our government understands that we need to attract the expertise. We need to accelerate the immigration path for the experts we hire from across the world. We cannot wait two years to have an expert if we need to begin production in two years.

I hope the government learned lessons from the pandemic and the problems of the supply chains that were caused by it. We need to bring a lot of manufacturing back to North America rather than relying on Asia, and what is better than manufacturing batteries that would help reach the net-zero emissions?

CMJ: How does NMG work with or engage Indigenous Peoples?

ED: We are committed to maintaining a collaborative and mutually beneficial relationship with our local communities and First Nations. Continued engagement with our communities, First Nations, shareholders, and stakeholders guides our growth and creates shared value. We have been actively engaging with the local community and the Atikamekw First Nation in our feasibility study. We also regard diversity as an important driver of strategy, creative thinking, and business performance. So, we promote local and First Nations recruitment opportunities to maximize benefits within our communities and ensure representation of our Indigenous Peoples.

Partnership with Indigenous Peoples is essential to the development of our sustainable business practices. NMG is committed to maintaining and enhancing our understanding of Indigenous perspectives, traditions, and knowledge while developing constructive and mutually beneficial mechanisms for collaboration. The Matawinie graphite mine is located on the municipal territory of Saint-Michel-des-Saints, situated in the large traditional Atikamekw Indigenous region, the Nitaskinan. The mining site is located 85 km from the Manawan First Nation community. We have consulted and continue to engage with the Atikamekw First Nation in the Manawan community and with the Band Council through the Conseil de la Nation Atikamekw in the development of our mining project.

In 2018, we signed a framework agreement, followed by a pre-development agreement in 2019 with the Atikamekw First Nation. We are progressing the impact and benefit agreement for the commercial phase of our mining project to maximize opportunities.

The Bécancour battery material plant is located on Ndakinna, the traditional Abenaki Indigenous territory, 5 km from the Wôlinak First Nation reserve. We are committed to engaging with the Wôlinak First Nation to learn about its heritage, interests, and culture, and to foster a mutually beneficial relationship.

First Nations’ communities have amazingly young population. So, we favor local training, employment, and procurement, as we want to help bolster the region’s socioeconomic fabric.

Comments

michel picard

What about Tesla visiting Phase-1 installations in St-Michel-des- Saints at the end of August? Work in progress or Tier-1 manufacturer deterred by lackluster project ?