Reclamation costs for a mill and waste rock pile

In the U.S., mines on public land, and some state lands, must put up a bond for the cost of the closure of a mine before construction can start. This is meant to ensure that funds are available to reclaim the site if something happens and a company abandons a mine. Those bonds are periodically reviewed and revised as projects change and grow, or as parts of a project are reclaimed concurrent to operations.

Doing concurrent reclamation for a mine can be beneficial. It is assumed that the equipment and workforce are already on site and the reclamation progress can be easily, and inexpensively, monitored. As parts of the mine have fulfilled their usefulness they can be reclaimed and with regulators’ approval, released from the bond. This helps the company save money on their bond or reapply it to a new area of the mine that is open to development. For example, a waste pile has been filled to capacity, an operator often chooses to reclaim it as equipment and labour is available, and then have that bond money released, while the mine is still in operation, and apply the bond to a future site for a new waste pile.

The following is an example of a small reclamation model that shows the cost of a bond that can be released. The model was created using Costmine’s Reclamation Cost Estimator. This example does not represent an actual closure project. The model details the costs to remove an abandoned mill building on a two hectare mill pad and an associated waste rock pile. The waste rock pile is 100 meters by 100 meters and 50 meters high. There is a topsoil stockpile that is located 1.0 km from the waste pile and another 500 meters to the mill pad site.

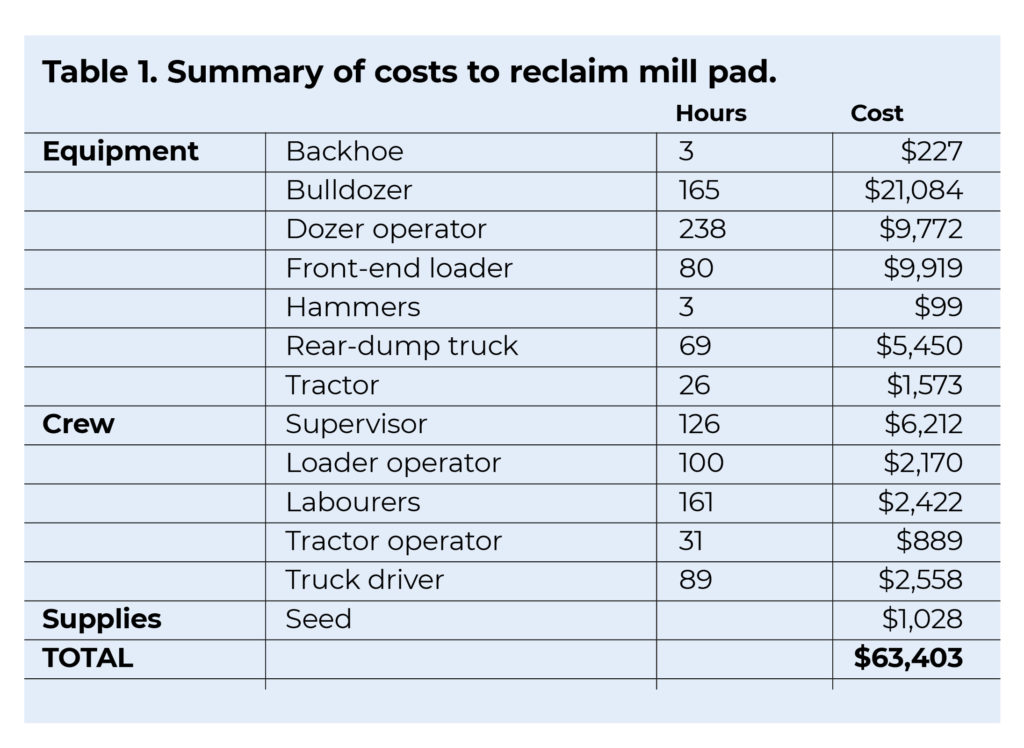

Mill pad

The mill building is assumed to have already been decommissioned and empty. The building is 50 meters by 50 meters and is 30 meters to the eaves and sits on a 16-cm-thick concrete foundation with rebar reinforcements. The area is a two hectare pad. The costs include removing the building and foundation and then spreading topsoil on the pad and planting a seed mix that is specific to the site.

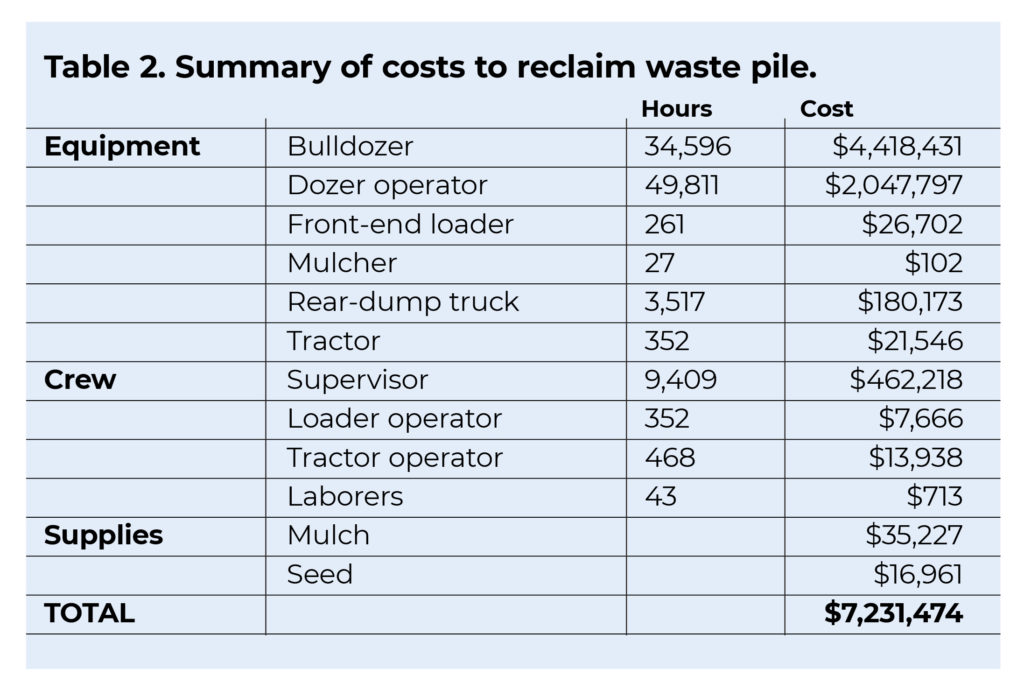

Waste pile

In this model, the waste pile will not need to be moved anywhere. The pile can be resloped and recontoured in place. This pile is assumed to be 500 meters by 500 meters and stacked 15 meters high. The four sides are sloped to 20°. There is a topsoil stockpile that is 1.0 km away from the stockpile at 2% gradient. The entire pile is capped with topsoil and seeded. In this model mulch was added to the slopes to reduce erosion and increase the seed capture.

Summary

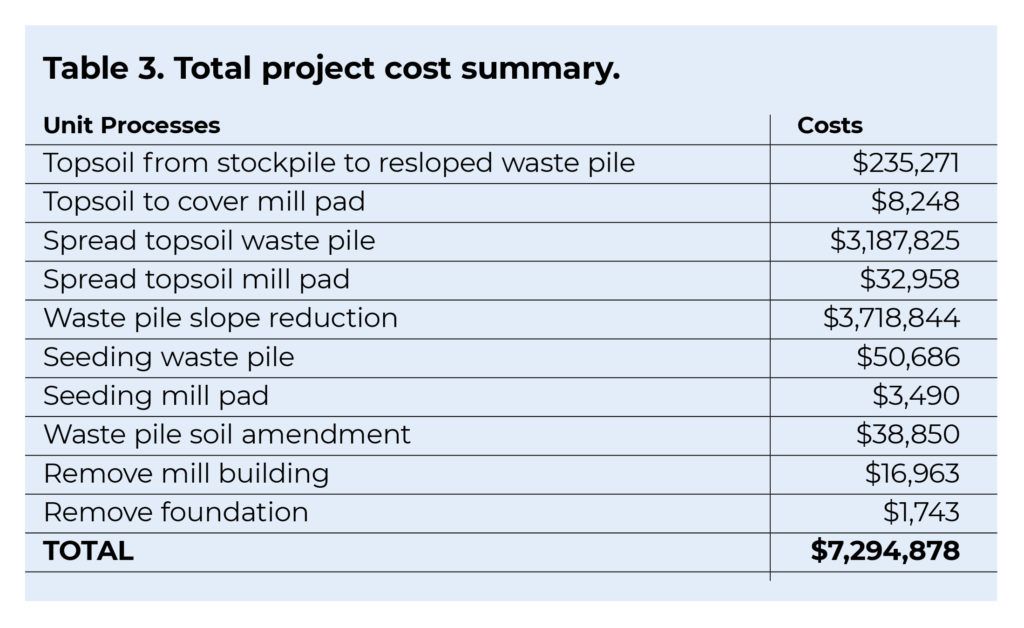

Table 3 shows the costs broken down by process. This table shows that the biggest costs in this model came from moving the topsoil to the mill pad and the waste rock pile.

Reclaiming this small mill and waste pile has a total cost of approximately $7.3 million. If this site were held under a reclamation bond the mine could apply for release of that bond. The Reclamation Cost Calculator includes mobilization costs and administrative costs to estimate the bond cost. Those costs were not included in this model calculation. Including those costs, the bond for this project would have been $8.5 million. That bond money can now be reapplied to another area, or released to the company, depending on how that bond was held. CMJ

This estimate was compiled using Costmine’s Reclamation Cost Estimator. Costmine publishes this software along with other mine cost estimating tools and software. (www.costmine.com)

Comments