STM-Screen

Copper Mountain Mining case study

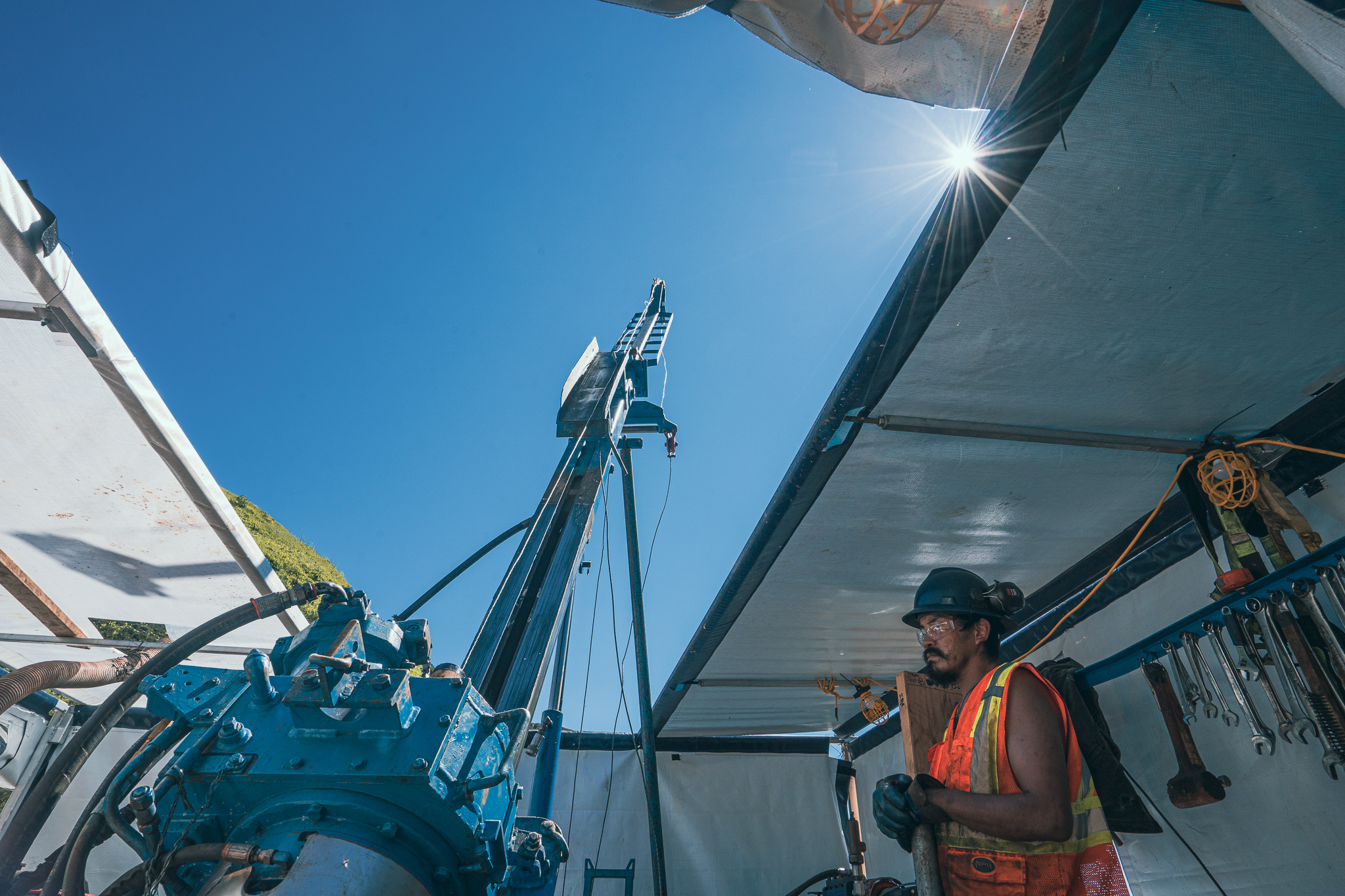

Copper Mountain’s flagship asset is the 75% owned Copper Mountain mine (CMM) located in the Canadian province of British Columbia near Princeton. CMM currently produces approximately 90 million lb. of copper equivalent per year.

Copper Mountain mine is a conventional open pit, truck, and shovel operation. The operation has a 40,000 t/d mill that utilizes a conventional crushing, grinding, and flotation circuit to produce copper concentrates with gold and silver credits.

The challenge

The SAG-ball-flotation circuit was initially designed for 35,000 t/d. A secondary crushing circuit was installed to exceed the original design and push the mill tonnage rate to 40,000 t/d. The increased circulating load led to the original SAG mill discharge screen overloading.

The initial screen was supplied and rated for a total infeed, including circulating load, of 2,298 t/h with 13 mm deck openings. Brute force screen design inherently dampens vibration under load, which adversely affects the screening efficiency. Once a brute force machine is overburdened, effective screening stops, and screen body and structure stresses increase significantly.

CMM, along with their previous screen supplier, committed time and resources trying to increase the screen capacity:

First, they declined the screen, expecting the increased angle would throw the material toward the discharge end faster. The change helped reduce overloading, but the screen’s structural failures continued, as the screening efficiency was affected negatively.

Second, the original screen OEM increased the wheel force and horsepower of the drive. Again, the change helped reduce overloading, but the screen’s structural failures continued and became more frequent. Each time the SAG mill had a surge (or burp), the screen would become overloaded, increasing stresses and leading to additional maintenance.

Brute force vibratory screens require significant horsepower and eccentric forces to operate. The increased horsepower induces a tremendous amount of stresses on the screen body, ultimately creating structural failures in just months. CMM experienced this firsthand and began scheduling downtimes to replace the screen entirely every quarter. The screen that came out of service would be rebuilt, costing them tens of thousands of dollars with each occurrence. Furthermore, each attempt to increase the throughput in the circuit also increased the frequency of repairs.

The goal

> With a stretch target of 50,000 t/d, CMM knew that the current screen bottleneck would need to be addressed. The new SAG mill discharge screen would need to achieve a sustained capacity of 2,400 t/h, with periodic surges to 2,700 t/h. This increase in capacity represents a 30% increase over the existing screen’s sustainable capacity (in the same screen footprint).

> To raise operational uptime and increase average daily capacity, the operations and maintenance team determined that reducing downtime associated with the screen was an essential requirement.

> Finally, the new screen would require minimal changes to the existing support structure, saving installation time and financial resources.

The solution

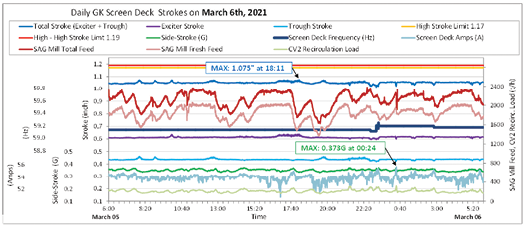

After extensive research, CMM selected General Kinematics’ STM-screen, featuring Two-Mass technology. The engineering principles behind Two-Mass technology are inherently more suited for the rigors of heavy-duty screening applications like the SAG mill discharge. The Two-Mass drive system responds to rapid increases in material loading by sustaining stroke. Whereas the brute force screen loses stroke and screening efficiency during surge conditions. Since the STM-screen does not dampen, screening efficiency and production continue to be maintained even during surge conditions.

General Kinematics provided a 3.6 x 8.5 metre STM-screen for CMM’s application. General Kinematics designed the screen to fit the existing mounting arrangement to reduce modifications and the related downtime during the switch.

The results

> The new General K STM-screen required no significant changes to the support structure to facilitate installation.

> Screen cracking issues have been eliminated (successful operation for more than two years with no structural problems). The Two-Mass drive system distributes drive forces evenly along the length and across the width of the screen and, therefore, dramatically reduces concentrated forces at any point. The reduction of these concentrated forces reduces/eliminates the cracking of side structures that lead to planned and unplanned downtime as well as the related expense.

> CMM reports maintenance costs have been significantly reduced by eliminating the quarterly screen rebuild program. With zero structural failures since installation, CMM has saved an estimated US$800,000 annually in time, material, and labor annually since installation.

> CMM reports that the screen is no longer the bottleneck restricting the increased daily throughput of the mill. The successful operation of the new screen will allow CMM to increase hourly/daily tonnage to an average hourly capacity of 2,400 t/h (including circulating load) with surges to 2,700 t/h once the new ball mill (No. 3) comes online.

> Screening efficiency has improved, allowing the operators to “manage” the screen panel apertures to achieve higher recoveries throughout the overall comminution circuit (resulting in more “sized” material reporting correctly to the ball mills).

The STM-screen will allow mill operators to increase throughput as soon as the downstream processes are expanded with the installation of ball mill #3.

Both immediate and long-term average capacity goals have been exceeded, and the screening quality has improved due to the longer retention time of material on the screen deck. General Kinematics’ STM-screen retains material for approximately 26-33 s versus a typical brute force screen that retains material for approximately 6-8 s. The longer retention time allows for an optimized material separation as fines have more time to drop out. Equally as important is the ability of the STM-screen to process at a higher bed depth without sacrificing throughput. The material spreads out evenly at the feed end, even at higher bed depths. The increased retention time of the evenly spread material allows for increased screening efficiency at the required capacities.

SUMMARY

• Maintenance costs due to structural issues have been reduced by approximately US$800,000 annually.

• Unscheduled downtime associated with screen structural failures has been slashed to near zero.

• Capacity will increase from an average of 1,800 t/h (fresh feed) to over 2,400 t/h.

• SAG mill transfer sizing to the ball mills has been reduced, allowing a finer overall grind with a corresponding improvement in overall recoveries.

The result is that CMM has removed the SAG mill discharge screen from the list of plant bottlenecks and is now able to plan for further plant capacity growth with the installation of a third ball mill.

Comments