Costmine: Passive road runoff treatment

There are a lot of factors in the costs of building a mine road. Some that many people do not think about. One such factor is whether the locally sourced rock might be acid generating. If the mine rock is an acid generating rock, the mine might choose to study the economics of hauling in a non-acid generating, or an acid neutralizing material instead of treating the road runoff.

Costmine has put together a model of the costs of passive water treatment for mine road runoff. In this model, we looked at the cost of building a mine road that is lined with a geosynthetic liner with a ditch to one side. The ditch is filled with acid neutralizing limestone to act as a semi-anoxic limestone drain with a 25-year lifetime. The ditch is designed to collect and treat precipitation that falls on the road and ditch surface and is sized to handle a worst-case event. The passive treatment system is designed to raise the alkalinity of the water from the road as it flows through the limestone into an onsite pond.

Building the road

Four different road widths with three different thicknesses are compared. The road in each scenario is 8 km in length. The underlying surface is already prepared for road construction, including the addition of the geosynthetic liner. Roads 1.0 meter thick are constructed with a 0.5-meter base course and a 0.5-meter wearing course. Roads 1.5 meter thick are constructed with two layers of base course and one layer of wearing course. Finally, roads 2.0 meters thick are constructed with three layers of base course and one layer of wearing course.

In each case, the same construction equipment is used for comparison purposes. However, if a mine is building a 24-meter-wide road rather than a 12-meter-wide road, one could assume that the equipment on hand would be larger and more appropriate for the situation.

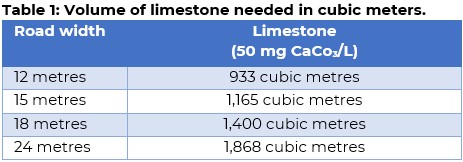

The ditch represented in this model has limestone with the alkalinity concentration of 50 mg calcium carbonate (CaCO3) per liter. The volume of limestone needed for an 8 km road with this concentration is shown in Table 1.

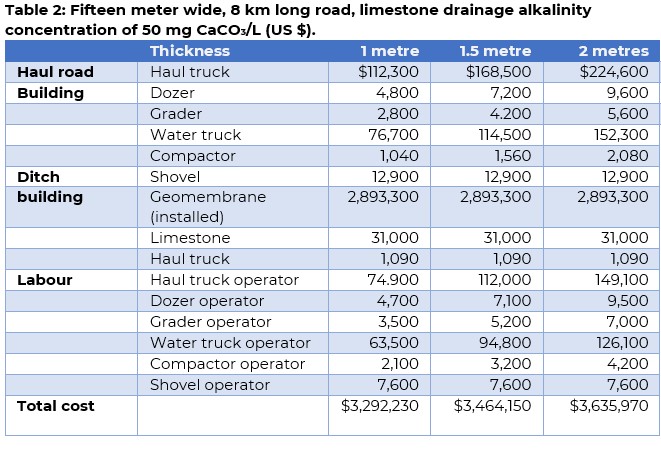

Table 2 shows the breakdown of costs included in this estimate for the 15-meter-wide road in all three thicknesses.

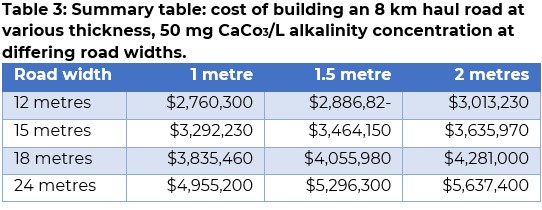

Table 3 compares the estimated costs of building an 8 km haul road at various widths (12, 15, 18, and 24 meters) and 3 different thicknesses (1, 1.5, and 2 meters) with a semi-anoxic limestone drainage system of 50 mg CaCO3/L.

The biggest cost to this passive water treatment system is, of course, the liner and installation. The cost of neutralizing limestone is small in comparison. If the option to use non-acid generating material is available, that cost can be compared to this one to determine the best economic decision.

This estimate was compiled using Costmine’s Mine and Mill Equipment – A Cost Estimator’s Guide and Reclamation Cost Guide. Costmine publishes these tools along with other mine cost estimating tools and software, and the Reclamation Cost Estimator. (www.costmine.com)

Krista Noyes has worked at Costmine for 15 years as a Reclamation Specialist and Compensation Analyst.

Comments