Using the sun to power Canada’s remote mines

NWT communities’ experience with solar suggests limits to viability

Remote mine sites depend on reliable and consistent electric power generation, not available from a grid or local municipality. Underground mines and milling operations are particularly sensitive to outages, often resulting in significant downtime and major safety concerns. Imagine a ventilation system going down or a hoist unable to bring miner back to the surface.

Power at remote mine sites is often generated by diesel (heating oil), propane (LPG) or hydroelectricity. Many companies are now also considering solar and wind as a way to augment, but not replace, current systems. This article will focus on the performance of solar photovoltaic (PV) panels in northern Canada in comparison to diesel generation.

Remote mines rely primarily on diesel

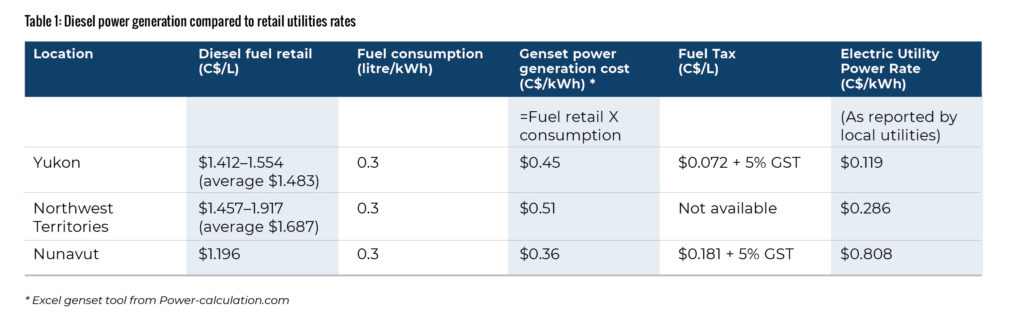

The table below illustrates the cost of power per kilowatt hour for diesel generators as compared to published electric power rates provided by utilities in the Yukon, Northwest Territories and Nunavut, where available. Generators larger than 40 kVA consistently consume 0.3 litres of fuel for each kWh of generated power at a 75% load. Using local retail diesel fuel costs, the table calculates the cost of diesel generated power compared to the cost of commercially generated power for remote locations as reported by the utilities.

For simplicity this comparison ignores cost of fuel transport, substations, switching, transmission facilities and utility overheads because those costs are small compared to electric power requirements for mining and related milling combined operations.

A recent Costmine survey of retail electric power rates in Canadian northern communities reported power rates ranging from less than $0.15/kWh to over a $1.10/kWh. As fuel prices increase, generated power using diesel gets more expensive.

As electric power costs rise, mining companies and communities are experimenting with, or integrating the use of, solar photovoltaic (PV) systems. Here we examine performance from the solar PV data record for the two communities designated as Site 62 and Site 67, named to identify differing latitudes that have installed modern solar PV systems.

Hourly data records from these solar installations give us a chance to see how solar PV systems could integrate with other electric power generating options at remote mines.

Community solar PV data

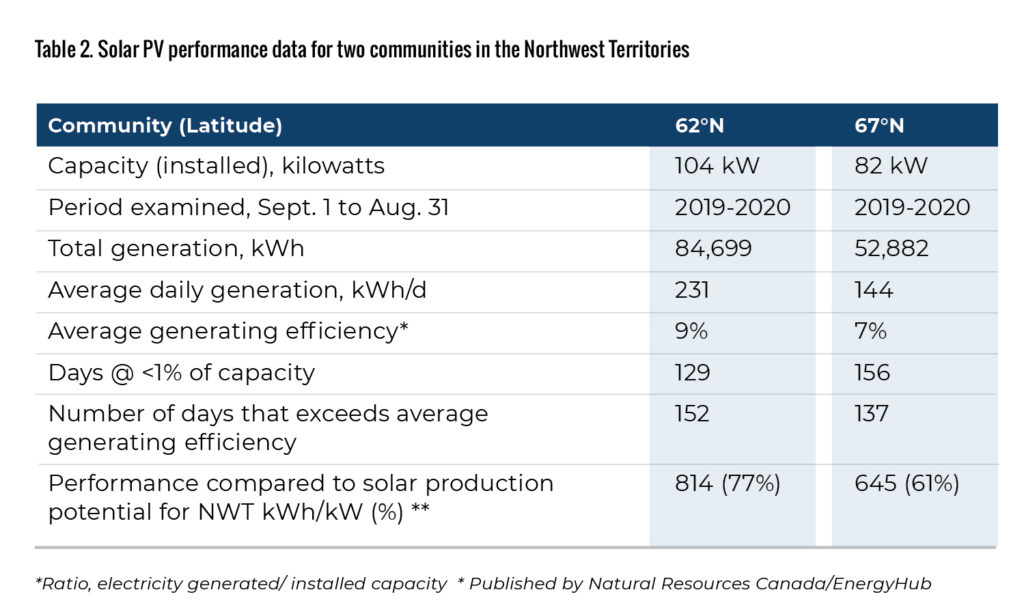

We took a look at the performance data for two communities in the Northwest Territories that have installed solar PV systems. Site 62 is located at 62° N. latitude and Site 67 is located at 67° N. latitude.

Site 62 installed a 104-kW, 437-panel system in 2012 at a cost of $1.07 million, consisting of 436 stationary panels 91 metres long and 4.2 metres high. A battery backup is not included.

Site 67 installed an 82 kW, 330 panel system in 2016, linked with battery storage for a total cost of $7.7 million.

Both communities use diesel-powered electric as a baseload source of generating electricity, with hydroelectric and the solar PV systems for backup electricity. The addition of solar PV adds complexity to the system by challenging grid operations and stability of power frequency due to the intermittent nature of solar generation. The battery backup system allows more flexibility for Site 67.

Unanticipated load swings increase the potential for power outages. To address such issues and protect customers, operators are limiting the solar PV portion to 20% of kW load needed for each community. For example, the allowable solar PV energy for Site 67 is 15 kW average load to meet the 20% limit. In this case, Site 67 also installed net-metering and battery storage to stabilize the grid. This allows the operator to exceed the 20% limitation.

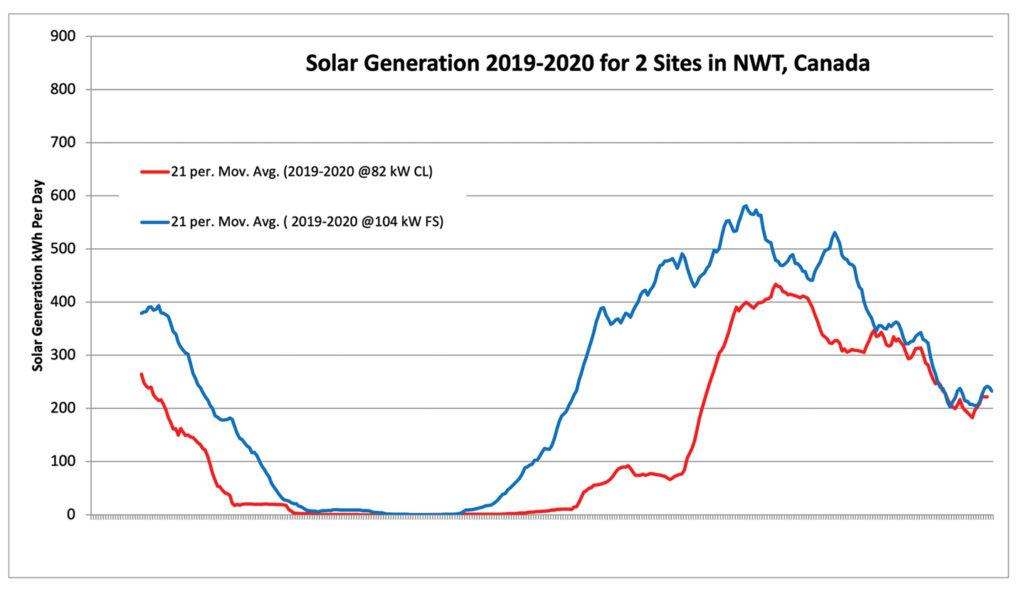

Illustrated in Figure 1 are records of daily output in kWh per day (with curves smoothed using a 21-day moving average) for Site 62 and Site 67.

Total generation for one year ranged from 52,882 kWh at Site 67 to 84,699 kWh at Site 62 (Table 3). Average daily generation and average generating efficiency are each less at Site 67 due to its location at 67° N. latitude. Efficiency is the average generation compared to capacity at a site.

The solar PV collects more energy at Site 62 with fewer days in darkness (defined as <1% of capacity) in winter and a greater number of days that exceed average capacity.

To anticipate potential to generate electricity within any Canadian province from solar PV, EnergyHub/Natural Resources Canada provides valuable guidance to estimate the expected electrical generation and the cost. From results shown here, caution is advised because data for the communities investigated demonstrates that solar PV output was much less, ranging from 61% at Site 67 to 77% at Site 62 compared to estimates provided by EnergyHub. The comparison shows that the latitude of the collecting array for solar PV is an important consideration. According to Energy-Hub, the average cost of solar power equipment is $3.01 per watt installed or $22,500 for a 7.5-kW system.

Other considerations

It is clear that solar EV electric generation is possible in the Far North, but is it practical? Energy gathered by a solar panel depends on latitude, amount of sunshine, incidence angle (orientation), age and several other factors. The National Renewable Energy Laboratory finds that solar panels degrade with time by 0.8% per year, so efficiency of a 15-year old panel will degrade by 11.3%. Most studies assume that solar panels have a maximum life of 25 years, but in Germany the mean scrappage age is 17 years.

As part of their efforts to limit fossil fuel usage, mining companies are considering adding solar generation to augment other power sources. While solar panels can be used in the Far North, the lack of sunlight in the winter make this a costly option based on the experience at sites 62 and 67 in the Northwest Territories. However, as technology improves and fuel becomes more expensive, solar PV systems can be an option for companies seeking a lower carbon footprint.

Since 1990, Costmine has been surveying Canadian mines, governments and suppliers for the latest capital and operating costs. For more information or to purchase these studies, please contact Costmine +1 (509) 328-8023 or www.costmine.com.

Comments