The digital proposition

A panel at this year’s PDAC looked at the progress so far.

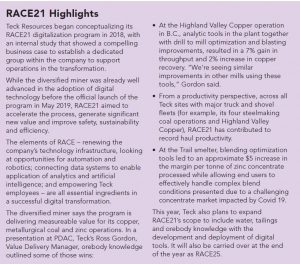

With its RACE21 program, which launched in 2019, Teck Resources set out to be a leader in the digital transformation under way in mining.

And while the initiative has produced real gains in productivity across its Highland Valley Copper and metallurgical coal operations in British Columbia (see RACE21 sidebar on page 26), those results are not yet fully appreciated by the market, said Kalev Ruberg, Teck’s VP Future and chief innovation officer, at this year’s virtual Prospectors and Developers Association of Canada conference.

“The transition has been so fast and effective that analysts have had very little time to react – and they’re not used to looking at this type of change within a mining company and gauging its effect,” Ruberg said in a panel on digitalization at PDAC moderated by Angelina Mehta, director of mining investment banking at Laurentian Securities.

The difficulty is that while digitalization has created real value, quantifying that value is not necessarily easy to do – even though digitalization is all about collecting, measuring and acting on data.

“These investments actually diffuse their value across the entire company,” Ruberg explained.

“You’re changing the way that processing is done by 2% or 3%, but the diffusion of that value is across not only the processing but it begins with the haul, it begins with mining, and goes all the way back through logistics.”

Unlike investment in a physical asset, like a SAG mill that allows you to pinpoint an improvement in production, with digitalization, you get better production by using the same assets in a different way, Ruberg said.

“You’re actually learning from the data that these assets are producing, so the assets are not only producing ore and metals – they’re actually producing data.”

While he didn’t provide specific numbers, Ruberg noted that “the effect on EBIDTA has been significant and positive,” and that consultants McKinsey have estimated digital innovation has the potential to add 11-16% to the mining industry’s net income by 2025.

“The early, quick value generation in 2019 and 2020 – even during Covid – more than convinced Teck’s leadership of the scale and scope necessary to achieve that significant change in value. The operational results both from a cost and production basis really bore that out during both years,” Ruberg added. “Now again, because it’s diffused, it’s very hard to say well that actually made this difference, but in the operations, the folks who are operating these assets can pinpoint that value.”

Kalev Ruberg. CREDIT: TECK RESOURCES

Getting there

Mining companies have been focused on digitization – embedding technology into infrastructure to create a digital capability behind the physical assets, said Colin Williams, executive enterprise architect at IBM. The next step – digitalization – will essentially create assets that can think.

“Through a digitization approach of using technology like IoT, sensors, 5G, we’re actually creating an infrastructure that will bring data out of the physical environment for us to be able to move into digitalization,” Williams said. It’s at the digitalization stage data is infused into an organization’s day-to-day capabilities to drive insights that will really allow it to improve efficiencies and focus on making the right decisions.

Although the mining industry has been automated for many years, and generates an incredible amount of data, Williams noted that the next level will be to curate the data.

“How do we bring this collection of data into insights that help individuals make better decisions, automate their processes and help them do their day-to-day work more efficiently?”

Importantly, digitalization underpins the shift toward greater ESG transparency and decarbonization, Ruberg noted.

“All the companies have set goals – 2040 GHG neutral, 2050 GHG free. How we get there depends very much on digital,” he said.

“Some of the technologies are future technologies – all of them rely on being able to control a very, very complex environment. And not only control the environment, but as Colin said the data have to behave on their own – they have to become their own masters in a way.”

While Teck and other majors are taking a wholesale, comprehensive approach to digital transformation, smaller miners don’t have the resources to follow that approach – at least not without some help.

One such place is Oren Marketplace, a platform created by IBM and Shell that aims to connect buyers and suppliers of digital technology for mining.

Mark Hannan, U.S. digital venture lead with Shell, noted that the platform has attracted clients of all sizes since it launched in mid-2020, during the pandemic.

“Companies don’t know where to begin with digitalization,” he said. “They can buy a solution from one provider, but how do you integrate that is the big part.”

Teck Resources’ Highland Valley Copper mine in B.C. CREDIT: TECK RESOURCES

Large mining houses, which usually have centres of excellence, look to Oren for help integrating various solutions. Medium-sized companies need help creating a digitalization roadmap and a business case outlining ROI and spend. Smaller companies generally ask for help finding a specific product or solution, Hannan said.

“Smaller clients will say I have X problem, can you help me solve it? They have very specific problems because they haven’t really thought strategically beyond the here and now.”

That said, specific solutions, such as Rithmik Solutions’ predictive maintenance Asset Health Analyzer (AHA) for mobile mining equipment – which is on the Oren platform – can generate real and measureable value for companies.

The solution, which uses multi-tiered AI/machine learning to create a digital twin of equipment, shows early on when something is off for that equpment in that specific mine’s context and provide notice of failures well in advance.

Rithmik co-founder and CEO Amanda Truscott said the offering, which is on the Oren platform, can save between $10 million and $50 million a year depending on type and size of mine, taking into account the reduced cost of maintenance and downtime along with reduced fuel consumption.

Creating a digital culture

A central theme of the panel was the importance of culture in pulling off a successful digital transformation.

“This needs to be put into the perspective of an organizational strategy,” said IBM’s Williams. It needs to be aligned and driven both from the top down and bottom up; and it needs to evolve as a culture within an organization.”

Boards can help drive organizational change by creating and communicating passion around where they’re leading the company, Williams says.

“It’s about people, not just technology. They need to see the vision, break that into proper programs, and address skill set issues,” he said.

And if the board wants to go one step further, they should be using augmented intelligence at the corporate level, as well as making it available to maintenance technicians.

“The big question for indivuals is do I trust the data, do I trust augmented intelligence to help me make right decisions – we have to foster that culture,” Williams said.

“I don’t think I’ve seen a board rely on an augmented intelligence assistant in making their decisions over strategies. Why not? The data’s there,” he said. “Do you trust in the data? Use that data with augmented intelligence to help make the right decision and profile it throughout the organization. It’s not just about setting the direction and guiding, but using it as well.”

Rithmik’s Truscott added that while the pace of digital adoption in mining is accelerating, there’s still a lot of fear about new technologies – something that is important for mining leaders to acknowledge and address.

It’s also essential to make room for employees to experiment and make mistakes.

“An important element of creating a culture of innovation is creating a foundation of psychological safety – where people feel it’s OK to learn and grow and make mistakes. Innovation by definition requires those things,” Truscott said.

Even though this is extra challenging in mines because physical safety is “paramount,” she suggested it can still be done. “Building a culture of innovation there means building a space or enclave where it is specifically OK to make mistakes.”

Comments