How traceability can lead to better ESG integration along the battery value chain

Over the past decades, companies have seen the world change quite significantly. Maximizing profit is no longer the only objective of C-suite executives. Many companies are also focused on concepts such as sustainable development and environmental and social responsibility (see, for example, the World Economic Forum’s Global Risk Report 2020). This comes as no surprise. In line with rising global concerns about climate change and the environmental and social footprint of human activities, citizens and consumers are asking new questions about the provenance of products. This has lead to increased demand for FSC (Forest Stewardship Council)-certified paper and pieces of furniture; fair-trade and/or locally sourced food and clothes; certified sustainable seafood; etc.

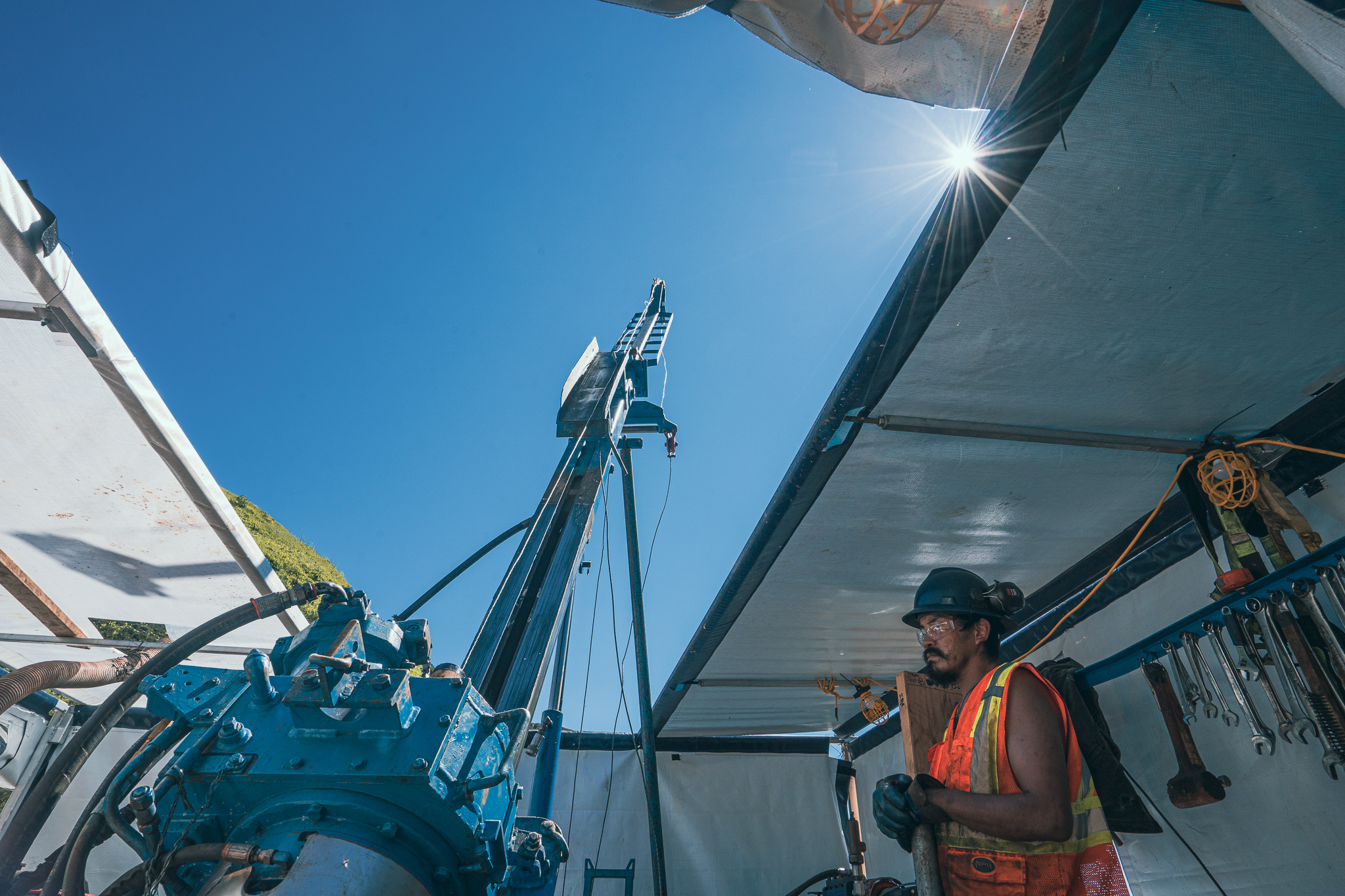

However, in recent years, this trend has moved into industrial sectors such as mining. Consumers want to know the impact of the products they buy all along the value chain. This is especially true in the context of increasing demand for critical minerals to feed a rising global demand for battery-powered electric vehicles. In its 2019 report on key trends in the mining industry, Deloitte mentioned that “as customer demand for battery minerals rises, so too does the demand for transparent provenance. This is exposing miners to increased scrutiny as socially conscious consumers question the origin of raw materials in products ranging from cell phones to electric vehicles. As a result, downstream customers – such as automotive manufacturers and tech giants – are demanding ethically sourced minerals. This is driving the adoption of technologies to enhance the traceability of commodities.”

New standards do not mean full transparency

To demonstrate compliance with environmental, social and governance (ESG) best practices, the industry has developed many new initiatives, tools, standards, and certifications. These include: the Global Reporting Initiative; OECD’s Due Diligence Guidance for Responsible Supply Chains; UN’s Global Compact Principles; the Initiative for Responsible Mining Assurance; and the Responsible Minerals Initiative.

These initiatives and standards are increasingly being driven by end-users. Companies such as Tesla, Volkswagen and Daimler recently adopted policies and/or announced purchase agreements focusing on ESG integration and reduced carbon footprint in the wake of increased scrutiny by consumers, especially when it comes to battery minerals powering a green transition of transportation.

Of note for Canadians, the Mining Association of Canada’s Towards Sustainable Mining and UL Canada Ecologo certification for mining exploration are getting attention worldwide. This is of course on top of recent federal and provincial guidelines and policies being published almost on a continuous basis and thus making Canada’s normative and legal framework one of the best internationally in terms of environmental and social responsibility.

However, these initiatives all miss the target: they are either too focused (ex. cobalt only) or lack capacity to track compliance all along the value chain. Because most standards or certifications are tools that do only apply to specific stage(s) in the value chain, they do not account for compliance at all levels at one time. Therefore, to answer consumers’ demand for real transparency, ESG compliance needs to be tracked all along the value chain, from the mine to end-users.

A solution: traceability

The question should then be the following: now that we have good ESG standards in place, how can we have them apply all along the value chain and track that compliance from upstream to downstream? The solution is the implementation of traceability mechanisms (hardware and software). Traceability is a powerful tool based on big data management. It enables monitoring and tracking a product through the various stages of processing, from ore extraction to integration in electric vehicles, to guarantee compliance with the applicable normative and legal framework at each step. A traceability mechanism can thus not only focus on technical aspects such as chemistry and QA/QC, but as well on ESG aspects such as greenhouse gas (GHG) emissions, water use, waste management, human rights, fair labour practices, progressive board composition, business ethics, community relations, First Nations and free, prior and informed consent (FPIC), etc.

A competitive advantage for Canada

In the Canadian context, the aforementioned stricter normative and legal framework applicable to mining activities (environmental protection, health and safety, community relations) could then turn out to be a competitive advantage to promote Canada as a responsible supplier of battery minerals to the EV industry. This is even more true in provinces like Quebec, where clean and renewable hydroelectricity is the main source of energy and thus the GHG emissions associated with mining and processing activities are significantly lower compared to the other regions worldwide that have a similar abundance of critical minerals.

Implementing traceability mechanism would then not only demonstrate compliance to the highest international ESG standards, but also:

- Position Canada as a world-leader in the mining and processing of battery materials and components and attract investments using a “Canada brand” guaranteeing environmental and social responsibility all along the supply chain;

- Offer a competitive and commercial advantage to Canadian businesses through products that comply with automakers, large tech companies and consumers’ increasing demand for ESG compliance and provenance transparency;

- Support the development of local value-added, sustainable, and responsible supply chains of critical minerals, from ore extraction to recycling.

It should also be noted that traceability perfectly aligns with the objectives of Canada’s Battery Initiative and, at the provincial level, Quebec’s Critical and Strategic Minerals Plan, as well as recent announcements made by Natural Resources Canada with regards to joint efforts with the United States on critical minerals. It also demonstrates the capacity of Canada to act as a pioneer worldwide and support the development of promising initiatives such as the World Economic Forum’s Global Battery Alliance.

In the wake of a strong will in North America to relocalize critical supply chains such as those pertaining to batteries, Canadian elected officials know that it will not be possible to do so without having support first from local communities, but also, as demonstrated, from end-users that are asking for better ESG integration in the value chains of the goods they buy. Increased provenance transparency along the value chain requires implementation of traceability mechanisms which demonstrate ESG compliance from ore extraction; mineral processing; production of precursors, cathodes, and anodes; battery cells, modules, and packs; to final integration in EVs. Especially in the context of a post-COVID economic relaunch, there is here and now a major opportunity for Canada to build back its mining and manufacturing industry on promising, responsible grounds.

Simon Thibault is the regional director for Propulsion Québec in the Quebec area. He was previously director of environmental and social responsibility at Nemaska Lithium, and before that, was a consultant in environmental and social responsibility in the mining industry.

Comments