UTAH –

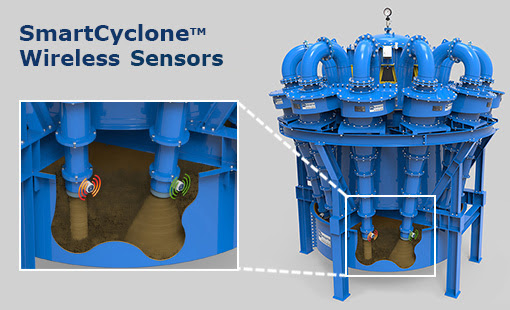

FLSmidth’s SmartCyclone™ is a monitoring and control solution for reducing cyclone-related process perturbations, improving cyclone overflow particle size distribution, predicting and controlling cyclone maintenance schedules, and optimizing closed-circuit grinding processes. The SmartCyclone closed circuit grinding optimization system, combines: FLSmidth Krebs patented SmartCyclone wear detection sensor technology, FLSmidth Krebs’ patented roping sensor technology with patent-pending wireless controller system, and FLSmidth Automation’s ECS/ProcessExpert process control software with new patent-pending SmartWear™ cyclone maintenance algorithm.

[caption id="attachment_1003715576" align="alignleft" width="300"]

A smarter way to monitor cyclone performance.

A smarter way to monitor cyclone performance.[/caption]

The new

Krebs wireless SmartCyclone sensor system eliminates the need for individual nodes and the interconnecting cables between the sensors and nodes and associated controllers. It utilizes a central wireless controller that can handle up to 16 sensors per unit; providing real-time wireless detection and communication of roping and /or wear data from the SmartCyclone sensors to the manifold controller(s) for forwarding to the control room workstation through an Ethernet cable.

The more compact system eliminates node boxes for each cyclone. A single central controller can monitor as many as 16 cyclones.

There are no cables or wires to install or maintain. The controller contains a wireless antenna that communicates with the sensors. There is no need to run cable trays, making a very streamlined installation.

Using the SmartCyclone monitoring and control solution in a closed circuit grinding system improved cyclone related processes through prediction and control of cyclone maintenance schedules, too.

Contact

FLSmidth for more information or a quote.

A smarter way to monitor cyclone performance.[/caption]

The new Krebs wireless SmartCyclone sensor system eliminates the need for individual nodes and the interconnecting cables between the sensors and nodes and associated controllers. It utilizes a central wireless controller that can handle up to 16 sensors per unit; providing real-time wireless detection and communication of roping and /or wear data from the SmartCyclone sensors to the manifold controller(s) for forwarding to the control room workstation through an Ethernet cable.

The more compact system eliminates node boxes for each cyclone. A single central controller can monitor as many as 16 cyclones.

There are no cables or wires to install or maintain. The controller contains a wireless antenna that communicates with the sensors. There is no need to run cable trays, making a very streamlined installation.

Using the SmartCyclone monitoring and control solution in a closed circuit grinding system improved cyclone related processes through prediction and control of cyclone maintenance schedules, too.

Contact

A smarter way to monitor cyclone performance.[/caption]

The new Krebs wireless SmartCyclone sensor system eliminates the need for individual nodes and the interconnecting cables between the sensors and nodes and associated controllers. It utilizes a central wireless controller that can handle up to 16 sensors per unit; providing real-time wireless detection and communication of roping and /or wear data from the SmartCyclone sensors to the manifold controller(s) for forwarding to the control room workstation through an Ethernet cable.

The more compact system eliminates node boxes for each cyclone. A single central controller can monitor as many as 16 cyclones.

There are no cables or wires to install or maintain. The controller contains a wireless antenna that communicates with the sensors. There is no need to run cable trays, making a very streamlined installation.

Using the SmartCyclone monitoring and control solution in a closed circuit grinding system improved cyclone related processes through prediction and control of cyclone maintenance schedules, too.

Contact

Comments