Pipes Before Profits

Flooding is usually a nightmare for miners, but for Selwyn Resources of Vancouver, the millions of gallons of water sitting in its newly purchased zinc and lead pit near Halifax weren’t that big of a problem.

In fact, when Selwyn took over the dormant ScoZinc mine from Acadian Mining Corporation in June of this year, dewatering the pit was not a major issue and certainly not a “deal breaker,” because they knew that under “Selwyn Lake,” as it is jokingly called, was one of the larger and more accessible zinc and lead deposits in all of Atlantic Canada.

Admittedly the 2.5 million m3 of water in the pit posed some concerns, mostly involving discharge procedures and the time it would take to remove it using at least five pumps, but on the overall business plan for the mine, dewatering was just a bit of a “nuisance” and not something that would take away from its game plan.

And that plan is to pump life back into the mine once the water has been pumped out.

Historically the ScoZinc mine was discovered in 1973 by the Imperial Oil Enterprises/Curvier Mines joint venture, and in 1978 Esso initiated mine development and commissioned a mill in 1979.

From 1979 to 1981, the mine produced 554,000 tonnes of ore containing 2.12% zinc and 1.36% lead.

In 1982, however, Esso closed the mine because of operating losses, largely brought on because of the difficulty it had dealing with groundwater conditions along the hanging wall of the mineralized zone. The cost of managing the groundwater inflow resulted in having to leave a hanging wall pillar that was comprised of high-grade material. It had nothing to do with depleting reserves.

Two years later, Seabright Resources Inc. of Halifax bought the mine and mill, but because of depressed metal prices at the time, they never reactivated but converted the mill for gold recovery and processing from several properties in the Nova Scotia Goldfields.

Over the years, ownership of the mine bounced around between a number of companies until in April 2006 when Acadian Mining Corporation bought it and, as mentioned earlier, held onto the property until earlier this summer, when they sold it to Selwyn for $10 million.

That $10 million price tag (which includes the Scotia Mine and 12,711 hectares of mineral claims covering much of the prospective geology in the Windsor Basin) was a bargain, because although Acadian only paid HudBay Minerals $7.5 million for the mine in 2006, they spent a further $21.4 million on the property, which included a $1.4 million royalty buyout, $13.3 for mill refurbishment and upgrades, $1.7 million for land and buildings, and $5.1 million for exploration and development.

Since the purchase and before the restart of the mine, Selwyn has already completed a new NI 43-101 to confirm mineral and expansion potential.

The April 2011 minerals resources to the NI 43-101 standards for the Main Pit at a 1.50% zinc equivalent cut-off value include Measured and Indicated mineral resource of 2,890,000 tonnes grading 4.20% zinc and 1.90% lead, and Inferred mineral resource of 1,570,000 tonnes grading 3.30% zinc and 1.30% lead.

The Northeast Zone at a 2.0% zinc equivalent cut-off value include Indicated mineral resource of 1,580,000 tonnes grading 4.21% zinc and 2.22% lead, and Inferred mineral resource of 1,880,000 tonnes grading 2.70% zinc and 1.86% lead.

Earlier drilling in a third area, the Getty Deposit located about 1500 m from the Main Pit, defined a near-surface mineral potential of 2.75 to 3.33 M tonnes grading from 2.09-2.21% zinc and 1.76 to 1.98% lead.

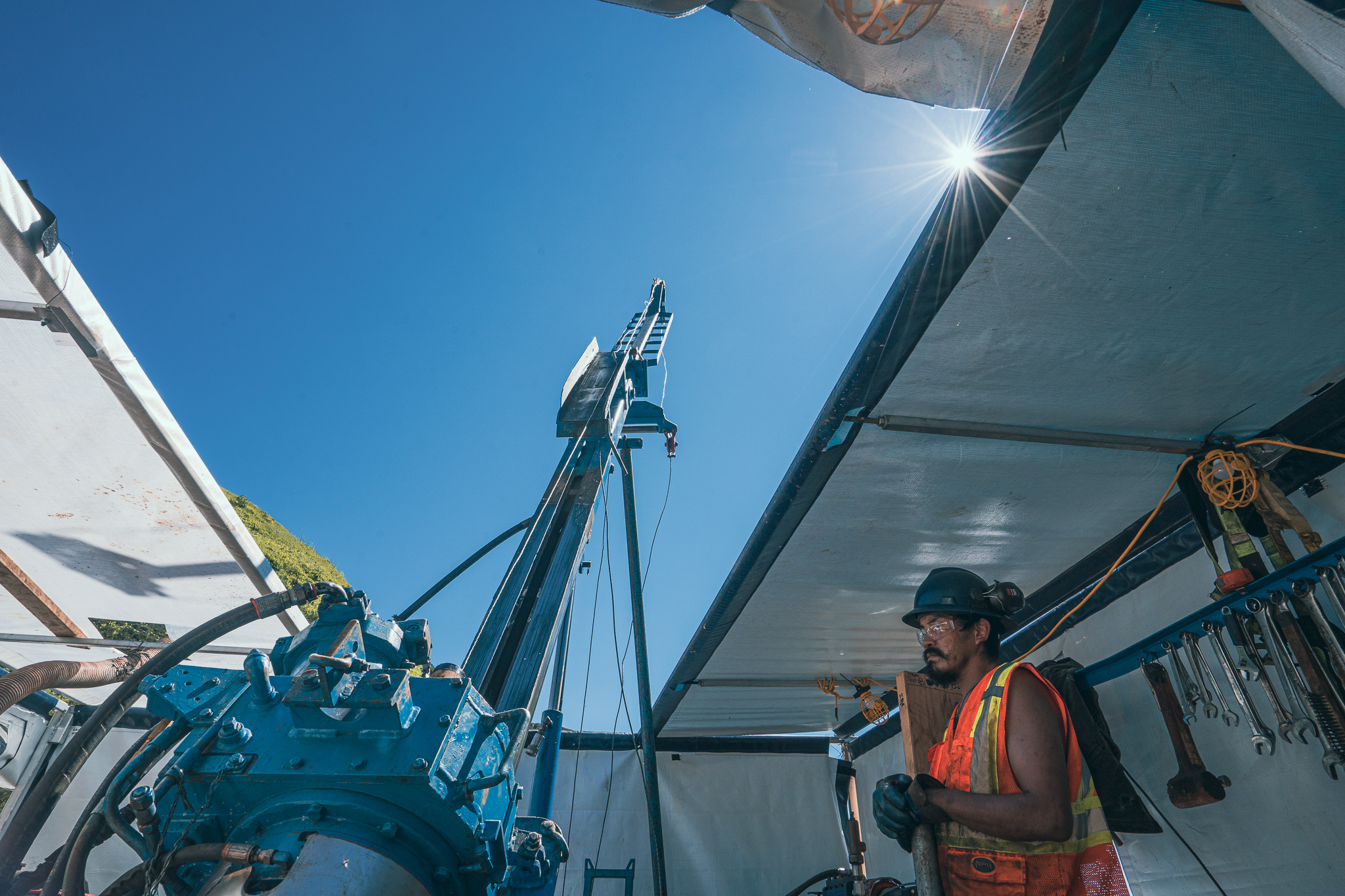

Most recently, Selwyn Resources signed a drilling contract with Logan Drilling Group of Stewiacke, N.S., to provide infill definition drilling and to conduct near-mine exploration in support of the mine restart activities.

Exploration drilling is now focusing on the exploration and mineral resources based on targets identified from a compilation of approximately 1,400 historical drill holes in and around the site.

Selwyn also owns approximately 42,080 hectares of mineral claims in Nova Scotia, (with 29,368 hectares staked in 2011) including coverage of numerous known reef structures with similarities to those that host the ScoZinc and Getty deposit.

Now, with a better understanding of what the newly acquired property contains and what the existing facilities are capable of producing, the company’s goal is to start with plant modifications, including redesign and replacement of the crushing circuit and concentrate filters. These modifications, together with improved plant availability, will allow average mill feed rates of 875,000 dry metric tonnes (dmt) per year or 2,500 dmt per day.

Projected feed grades for the first three years average 3.81% zinc and 1.69% lead (projected life-of-mine mill feed grades are 2.95% zinc and 1.64% lead). The projected metallurgical performance, based on historical data, provides for zinc concentrate grading 57% zinc at 86% recovery and a lead concentrate grading 70% lead at 88% recovery.

As for the actual mining, three conventional pits are to be mined sequentially in the zones mentioned earlier (Main, Northeast, and Getty), each of which was modelled using Whittle software. Production scheduling is based on an average of 350 operating working days a year.

The average strip ratio for the life-of-mine is 20.6 to 1 (excluding pre-stripping which is included in the capital cost. Approximately 58% of the waste is readily removed without blasting, including soils that will be used for reclamation; and 11% of the waste is gypsum, which may be marketable. Mine dilution and mining losses are assumed to be 10% and 5% respectively.

Selwyn technicians commend the previous owners for the condition in which they left the equipment under a controlled “Care and Maintenance” program and say that start-up will be relatively straightforward.

Adding to the ease of start-up is the mine’s infrastructure that includes low-cost power and an ample water supply. Paved roads lead to the mine property with nearby rail access, and ScoZinc has its own storage and concentrate loading harbour at Sheet Harbour with a capacity of 8,500 tonnes, or 1.5 times the expected shipment size.

General maintenance throughout the entire property is also underway as teams of technicians and workers concentrate on everything from replacing light bulbs in the mill, to installing new signage in and around the pit and storage areas, to painting the office facilities and adding “visitor” signs in the parking lot adjacent to the administration office.

Much of the work is “cosmetic” in nature to the mine’s true production and operations but Selwyn knows that an increasing number of people will be visiting the site over the next few months and first impressions are lasting in all walks of life… especially in mining.

Furthermore, the company is opening it doors to the neighbouring communities as they conduct a series of on-going meetings to help ensure that its plans for reopening the mine are clearly spelled out.

The meetings have also proven to be a good way of attracting a local workforce for the mining and milling operations at the reborn ScoZinc Mine.

Comments