Safe and Sound

A behind-the-scenes look at anything is always fascinating because it’s usually a place that is “off limits” or “restricted,” but every once in a while an opportunity comes along to take a backstage look, so to speak, at what goes on behind closed doors.

And that’s exactly what happened recently when international mining contractor Dumas invited Canadian Mining Journal on a day-long tour of its engineering and maintenance facilities in Timmins to see what goes into building and maintaining some of the heaviest and more complex equipment and structures used in mines around the world today.

From the moment you enter the 100-acre property near the heart of downtown Timmins, one immediately knows that the company is a streamlined, no-nonsense operation designed to get products in and out of the shop quickly and efficiently.

A huge, fenced inventory yard is located directly across the street from the 10,000 square-foot maintenance shop for ready access to parts and other large components, while directly adjacent to the shop is an equally large shipping and delivery yard where a steady stream of trucks, flatbeds and tractors with floats pick up and deliver equipment.

Inside and directly in line with the shipping and receiving area is where a team of 21 technicians ply their skills, as certified welders and fabricators, electrical and mechanical technicians and even a firefighter and an auto mechanic work from 7 to 4, Monday to Friday, repairing, refurbishing and fabricating mining equipment.

Starting with an indoor wash bay, all components arriving at the Dumas’ shop are pressure washed and scrubbed of all mud and grease so that the various technicians get a clear, and clean, picture of the problem at hand. Each machine or component is logged in, and subsequent “team meetings” diagnose the work at hand, and schedules and teams are created.

In addition to the initial wash bay, the 13-bay shop also features four mobile equipment repair bays, two pneumatic bays with a full complement of shaft sinking equipment, three welding bays and three Alimak repair testing bays including 6,000 feet of rail, 22 units, and a full complement of support equipment.

All of the work performed by the Dumas’ team is done under the supervision of a technician assigned to a specific job, but what the company is also doing is working with various technical schools in an apprenticeship program so that four students are always in the shop assisting with the work.

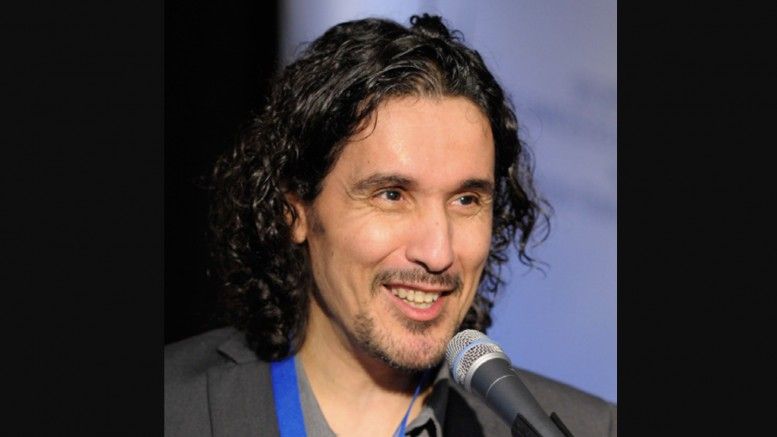

From complete rebuilds to general maintenance and repairs, the apprenticeship program is working well and as Greg Hart, Vice President says, “Helping train the next generation is something that is very close to our hearts because, like most companies associated with the mining industry today, we’re concerned that the shortage of skilled workers is going to continue to diminish over the next few years and unless industry steps up to help out, there won’t be a technical pool to draw from.”

Hart admits that there’s a certain degree of “selfishness” involved with Dumas and the apprenticeship program because “we know the senior technicians we have on staff are the best in the business but some of them will be retiring not too long from now and we want to be in a position to hire the people they have helped train. The old saying: “Learning from the Masters” really applies here.

“Basically, we’re planning for tomorrow because, quite frankly, we’re worried about the mining industry because at the rate we’re going, there won’t be enough bodies to go around, especially from the technical side, and that certainly goes beyond the shop and includes the people who work underground too.”

As mentioned at the outset, Dumas is also an engineering company and as many mining companies around the world know, they are considered one of the better full-service mining contractors in the business.

From mine construction and development to production mining, mine services and engineering, the company has been in the mining business since 1994 and over those years has been responsible for a number of well known projects.

For example, shaft sinking is probably one of the more technically challenging components of any mine design, and here are just a few projects the company is proud to say are “Dumas jobs.”

Among the company’s current projects is the contract from IAMGOLD Corp. for the excavation of a 5.5 m dia concrete-lined shaft to a depth of 2,000 m at its Westwood mine in Cadillac, QC. The job involved slashing an eight-foot Raisebore pilot hole with a two-boom jumbo from the surface to the 840 m level. Full face from 840 m to the bottom of the shaft in ongoing. Dumas is responsible for the excavation, shaft furnishings, miscellaneous construction and the changeover to production.

On equally grand and challenging scales, the company also excavated a 5.5 m dia concrete-lined shaft to a depth of 865 m for Agnico-Eagle at its Goldex Mine in Val d’Or, QC., and it also performed a similar excavation for Agnico-Eagle of a 4.9 m dia shaft fully lined with concrete to a depth of 1,360 m at its Lapa Mine in La Sarre, QC.

Dumas and Agnico-Eagle also worked together under challenging ground and heat conditions at the Laronde Mine in Val d’Or where a 5.5 m dia concrete-lined internal winze was excavated 835 m deep, to an ultimate depth of 2,858 m.

Closer to home in Timmins, Lake Shore Gold Corp called upon Dumas for the excavation of a 5.5 m dia concrete-lined shaft to a depth of 712 m at its Timmins West Mine. Scope of this work included surface infrastructure, collar excavation and construction, shaft excavation, station exaction, shaft furnishings, miscellaneous construction, changeover and final commissioning for mine production. This job also called for the addition of a 450 m Alimak Raise manway installation and a 150 m ore pass.

Also in Timmins, through a series of ownership changes from Kinross Gold to the Porcupine Joint Venture and finally with Goldcorp over a 10-year span, the company has provided engineering services. Alimak raise and shaft enlargement excavation and equipment in three deepening programs sustained mine decline and level development, mechanical and conventional raising and miscellaneous construction and rehabilitation services.

As the economy continues to recover and more and more mines come back to life, shaft rehabilitation and dewatering have become essential parts of many mining operations and, because of that, Dumas has once again been called upon to provide its experience and understanding to help ensure that older mines are made safe again.

In fact, millions of dollars in contracts have been awarded to the company for rehabilitation and dewatering work at various sites in Ontario alone.

Dumas was hired for shaft rehabilitation and dewatering at the Young-Davidson Mine in Matachewan, as well as the installation of services, hoist installation, headframe rehab, and a parallel lateral program including portal construction, ventilation raises, and associated mine construction over a four-year program.

At its Bucko Lake Project, Crowflight Minerals hired Dumas for the turnkey mine reopening and startup of the mine, including dewatering and shaft rehabilitation, portal construction, decline development and mine-level development, all Alimak and conventional raising, production blasthole, longhole, cut and fill mining, and underground construction and associated infrastructure. This $50 million project serves as just one more example of what the company can do.

On a little different type of project, but one that further demonstrates the scope of the company’s capabilities, River Gold hired Dumas to construct a mine hoisting plant inside a mountain side at its Eagle River Mine in Wawa.

The project called for a hoist room, rope raise, a 60 m headframe, 1,500 tonne ore bins, a dump station, substations and a 150 m pilot raise for a future shaft. Construction included all foundations, mechanical installations and comm

issioning of the mine plant. The company was also responsible for the design and engineering for an 800 m three-compartment steel shaft.

Impressive work to say the least but regardless of the number of jobs the company has to its credit, the one thing that it’s proudest of is its safety record.

As mentioned earlier, Dumas has a full complement of skills on staff (including the firefighter) but aside from their technical capabilities, Greg Hart says the company’s greatest asset are still the individuals themselves because of their attitudes and concerns for safety; in the shop, and on the site.

“What it boils down to is that our people genuinely care for one another and don’t want to see anyone get hurt.”

Further proof that the workers are safety conscious is clearly illustrated by the fact that the company also set safety milestones at four of its recent projects. At Xstrata Copper’s Kidd Mine in Timmins, more than 200 workers attained four years and 1.5 million man hours with no lost time from injuries, while also in Timmins, at Lake Shore Gold’s Timmins West Mine, 63 workers put in 1,195 days LTI free.

And at home at the maintenance shop where CMJ’s tour started, the 21 technicians and six employees in the office have set an outstanding record of 429 days of LTI free and counting.

“Here in the shop we attribute our safety record to a number of things. First of all, nobody wants or intends to get hurt, so that’s the first thing towards a safe working environment; but most importantly, everyone takes safety seriously and we see and hear that at our safety meetings every morning,” said Greg Hart.

Dumas is certainly not alone in its commitment to safety and providing the best qualified people available to get the job done because just about every company associated with mining in Canada approaches work in a similar manner.

Dumas and its people, however, go a little further in that its Health and Safety programs also include “staff input” during a Risk Analysis process whereby everyone assigned to a task or team is asked to identify any potential hazards, to measure the risks and to “put their two cents worth in,” insofar as where they think problems may arise.

It’s that total team approach that has made the company a leader in its field.

Comments