Close Counts

Eighty-five hundred and fifty kilometers isn’t exactly what you’d call “close,” but that’s how far Walter Energy Western Coal (formerly Western Coal Corp) has been shipping high-grade metallurgical coal from its mines in northeast British Columbia to its steel-making customers in Asia.

In terms of distance it’s a long way, but in terms of demand it’s a great opportunity for the company, because Asian steel makers are desperate for high-quality metallurgical coal and Walter Energy Western Coal has plenty of it.

In fact, from its Wolverine, Brule, and Willow Creek mines in northeast British Columbia, the company has in excess of more than 125 million tonnes of coal reserves, and what makes it even more impressive is that it’s all 100% metallurgical coal: an essential ingredient for making high-quality steel.

The company admits that it doesn’t have the largest deposits in the province but it certainly is proud to say that it does have the closest supply of metallurgical coal from North America to the Asian market. In fact, 36 hours closer than any other North American supplier; and that, regardless of what kind of manufacturing is involved, is a huge factor that sets good suppliers apart from the others.

Because Walter Energy Western Coal ships from the Ridley Coal Terminals at Prince Rupert, a 950-km trek by rail almost on the same latitude and directly across the province from its mines, the company saves valuable time in getting its coal to the port.

From there, like other coal suppliers who use the Ridley Terminals, it’s another 13 days of sailing at 13 knots across the Pacific Ocean to its Asian customers. That part of the excursion is a fact of life; but again, the reason Water Energy Western Coal gets a jump on the competition is because of where its three coal mines are situated.

The Wolverine property, the company’s flagship operation in the region, currently consists of the Perry Creek open-pit metallurgical coal mine located near Tumbler Ridge. Also at this location is the Perry Creek underground project, EB project and Hermann project, all of which are undeveloped but on track for future development.

Perry Creek produces hard-coking coal for export, primarily to Japan and Korea.

Located at the Wolverine Operation (main photo on Page 12) is a coal processing and rail load out facility that can handle 3.0 million tonnes of coal per year. The Wolverine property itself has more than 40 million tonnes (run-of-mine) of reserves and nearly 80 million tonnes of resources.

To keep pace with demand, the company plans to increase production from 1.5 million tonnes in fiscal 2010 to nearly 2.3 million tonnes in the fiscal year just completed, March 31, 2011.

From its Brule Mine, located slightly farther north near Chetwynd, the company produces ultra-low volatile pulverized coal injection (“ULV-PCI”) also for export, primarily to Korea and other Asian countries. Because of its high calorific value, low ash level and volatile content of less than 15%, this particular product has become one of the world’s premium “PCI” coals.

Currently the company is processing coal beyond crushing at a rate of 1.3 million tonnes a year but is in the process of modifying its operation to reach the 2.0 million tonnes a year this year.

The Brule Mine has more than 20 million tonnes (run-of-mine) of reserves and over 35 million tonnes of coal reserves.

Completing the company’s main Canadian supply line is the Willow Creek Mine, an open-pit metallurgical coal mine also located in the Chetwynd area.

This particular mine is currently undergoing an expansion and its processing plant and rail load out are being refurbished to ultimately handle 3.7 million tonnes of coal a year. Expansion calls to increase production from its current production rate of 900,000 tonnes a year to 1.7 million tonnes, which over the life-of-mine will consist of 1.1 million tonnes of (ULV-PCI) and 0.6 million tonnes of hard coking coal per year.

The mine has nearly 30 million tonnes (run-of-mine) of reserves and 51 million tonnes of coal resources.

From all three mines, Wolverine, Brule, and Willow Creek, the company expects to produce approximately 6.0 million tonnes of metallurgical coal a year by fiscal 2013.

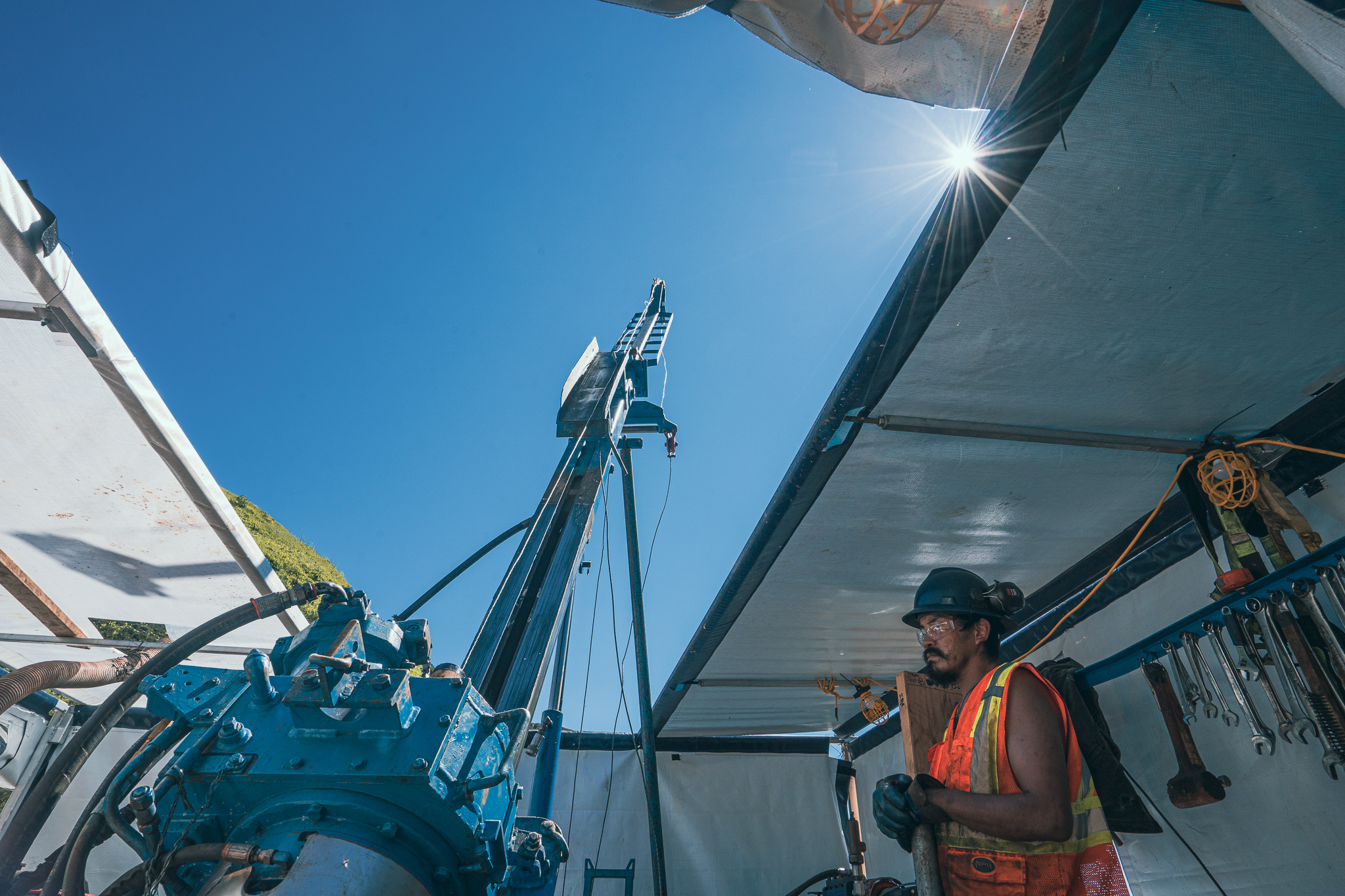

As can be imagined, extracting and processing that amount of coal a year requires a lot of equipment and, as described in the adjacent shadowed areas, Walter Energy Western Coal has invested heavily by equipping its mines with the proper tools.

In fact, the three mines contain the largest fleet of Caterpillar 793F trucks in the world and to date the company’s capital investment (not all on equipment) is now more than $850 million in northeast BC with a further $250 million of investments expected this year.

The company has more than 65,500 ha of coal licences/lease/applications in northeast BC (NEBC) under its control and currently has over 1000 people working for its NEBC operations (employees and contractors) and expects to hire an additional 300 people this year.

Expansion is the game plan for Walter Energy Western Coal, and last year the company spent more than $4 million on exploration and expects to top $9 million this year. The goal of the exploration program is to continue the company’s growth beyond 6 million tonnes in the region.

But again, equipment is one of the keys to the company’s success.

Currently it uses contractors at its Willow Creek Mine (Ledcor) and at Brule (Pelly) who use their own equipment to run the mines.

At Wolverine, however, the company uses 57 pieces of its own equipment (see adjacent box), and once Willow Creek and Brule are in a steady state of production, Walter Energy Western Coal will take over those operations too with their own employees and equipment.

As mentioned earlier, Caterpillar has a huge presence in the mines but so too do other heavy equipment manufactures like P&H LeTourneau, Terex, Komatsu, Atlas Copco, Ingersoll-Rand, Driltech and Hitachi.

Hitachi, for example, has some of the largest pieces of equipment at the mine and as can be seen by the photo above, they are huge machines that required a team effort from the manufacturer and its local distributor, Wajax of Tumbler Ridge, to get the equipment to the site in pieces and assemble it under field conditions.

Getting people and equipment to the Wolverine, Brule and Willow Creek coal mines in northeast British Columbia is no easy task, because they’re in a remote and scarcely populated part of the province; but as far away as they are, they’re still the closest sources of 100% metallurgical coal available to Asia, and Walter Energy Western Coal likes it that way.

Comments