[caption id="attachment_1003732891" align="aligncenter" width="450"]

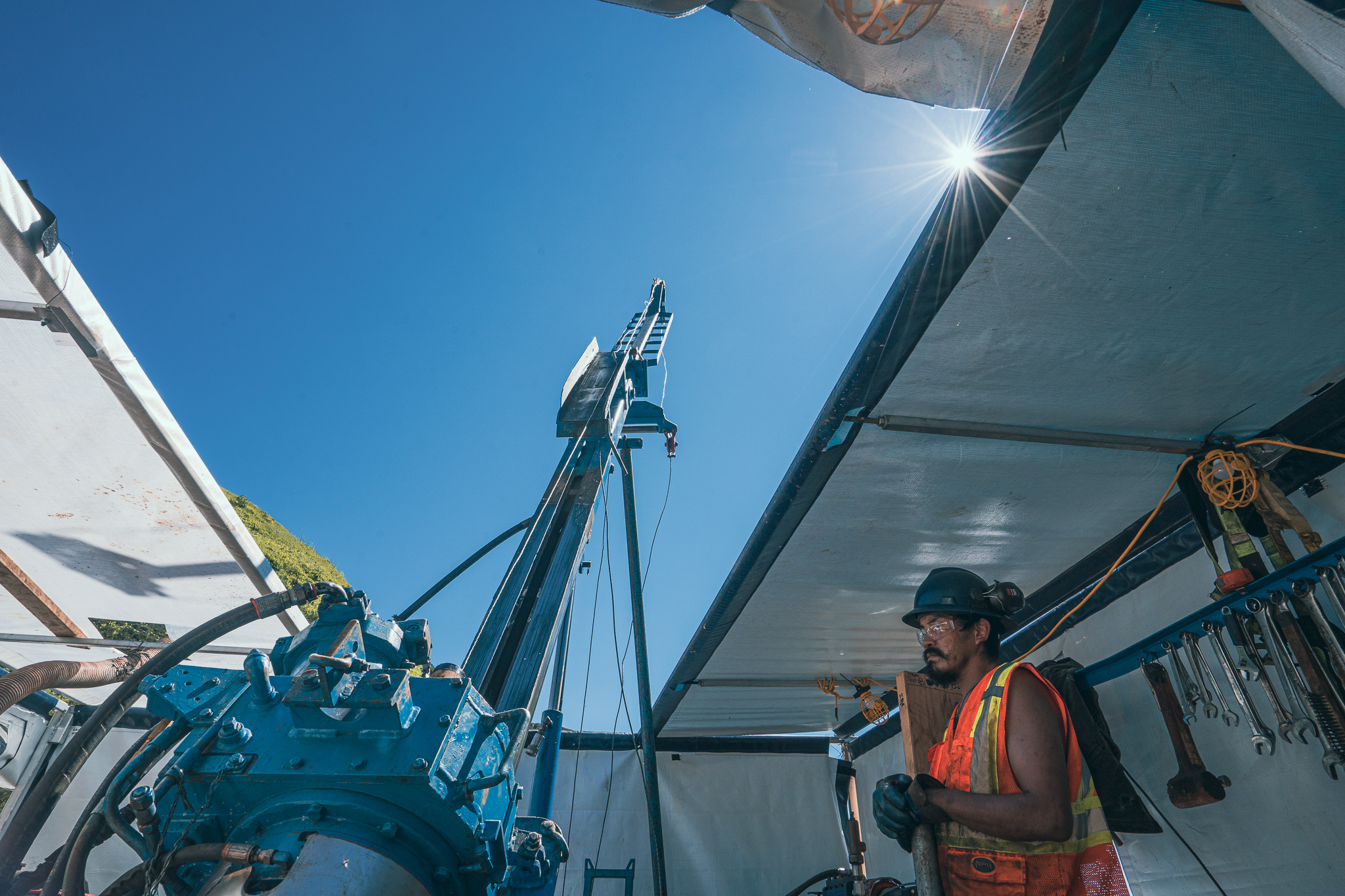

Baptiste zone at Decar Credit: FPX Nickel

Baptiste zone at Decar Credit: FPX Nickel[/caption]

BRITISH COLUMBIA –

FPX Nickel has released the results of pressure leaching testwork on nickel concentrates from its 245-sq.-km Decar nickel project located in central B.C. Based on nickel recoveries in excess of 98%, the company believes that the resulting solution could be an ideal feed for the production of nickel sulphate and cobalt sulphate through neutralization and solvent extraction.

These sulphate products are used in the manufacturing of electric vehicle batteries.

“These results confirm a breakthrough for FPX Nickel, demonstrating that Decar has the potential to produce significant quantities of nickel and cobalt in a high-quality form for the fast-growing EV [electric vehicle] supply chain,” Martin Turenne, FPX president and CEO said in a release. “This testing confirms the potential for the production of nickel sulphate and cobalt sulphate from awaruite ore in a simple three-stage process.”

The flowsheet proposed currently for Decar would entail flotation to concentrate the awaruite ore, followed by pressure leaching and then solvent extraction. Awaruite, the metal-bearing mineral for Decar, is a nickel-iron alloy composed of nickel and iron with negligible sulphides.

Unlike nickel sulphide concentrates, the Decar concentrate would not require smelting before further processing. In addition, due to its high-grade and consistent feed specifications, the pressure leaching of this concentrate is expected to be less energy-intensive than pressure leaching of laterite ores.

Two batch pressure concentrate tests were conducted in an autoclave with the resulting solution containing low acid and iron. Future testing will focus on downstream processing steps.

The company plans to complete internal trade-off studies to determine the optimal product mix from the project for the stainless steel and battery markets. Additional testing is also planned to refine the pressure leaching scenario and generate nickel products for marketing to potential offtake partners.

Decar hosts current resources of 1.8 billion tonnes in the indicated category grading 0.12% Davis tube recoverable (DTR) nickel for a total of 2.3 million tonnes of contained nickel. Additional inferred resources stand at 391 million tonnes grading 0.12% DTR nickel for 448,000 tonnes of contained metal. Current resources are contained entirely within the Baptiste deposit, one of four awaruite zones identified on the property.

FPX first drilled the Baptiste and Sidney targets in 2010.

For more information, visit

www.FPXNickel.com.

Baptiste zone at Decar Credit: FPX Nickel[/caption]

BRITISH COLUMBIA – FPX Nickel has released the results of pressure leaching testwork on nickel concentrates from its 245-sq.-km Decar nickel project located in central B.C. Based on nickel recoveries in excess of 98%, the company believes that the resulting solution could be an ideal feed for the production of nickel sulphate and cobalt sulphate through neutralization and solvent extraction.

These sulphate products are used in the manufacturing of electric vehicle batteries.

“These results confirm a breakthrough for FPX Nickel, demonstrating that Decar has the potential to produce significant quantities of nickel and cobalt in a high-quality form for the fast-growing EV [electric vehicle] supply chain,” Martin Turenne, FPX president and CEO said in a release. “This testing confirms the potential for the production of nickel sulphate and cobalt sulphate from awaruite ore in a simple three-stage process.”

The flowsheet proposed currently for Decar would entail flotation to concentrate the awaruite ore, followed by pressure leaching and then solvent extraction. Awaruite, the metal-bearing mineral for Decar, is a nickel-iron alloy composed of nickel and iron with negligible sulphides.

Unlike nickel sulphide concentrates, the Decar concentrate would not require smelting before further processing. In addition, due to its high-grade and consistent feed specifications, the pressure leaching of this concentrate is expected to be less energy-intensive than pressure leaching of laterite ores.

Two batch pressure concentrate tests were conducted in an autoclave with the resulting solution containing low acid and iron. Future testing will focus on downstream processing steps.

The company plans to complete internal trade-off studies to determine the optimal product mix from the project for the stainless steel and battery markets. Additional testing is also planned to refine the pressure leaching scenario and generate nickel products for marketing to potential offtake partners.

Decar hosts current resources of 1.8 billion tonnes in the indicated category grading 0.12% Davis tube recoverable (DTR) nickel for a total of 2.3 million tonnes of contained nickel. Additional inferred resources stand at 391 million tonnes grading 0.12% DTR nickel for 448,000 tonnes of contained metal. Current resources are contained entirely within the Baptiste deposit, one of four awaruite zones identified on the property.

FPX first drilled the Baptiste and Sidney targets in 2010.

For more information, visit

Baptiste zone at Decar Credit: FPX Nickel[/caption]

BRITISH COLUMBIA – FPX Nickel has released the results of pressure leaching testwork on nickel concentrates from its 245-sq.-km Decar nickel project located in central B.C. Based on nickel recoveries in excess of 98%, the company believes that the resulting solution could be an ideal feed for the production of nickel sulphate and cobalt sulphate through neutralization and solvent extraction.

These sulphate products are used in the manufacturing of electric vehicle batteries.

“These results confirm a breakthrough for FPX Nickel, demonstrating that Decar has the potential to produce significant quantities of nickel and cobalt in a high-quality form for the fast-growing EV [electric vehicle] supply chain,” Martin Turenne, FPX president and CEO said in a release. “This testing confirms the potential for the production of nickel sulphate and cobalt sulphate from awaruite ore in a simple three-stage process.”

The flowsheet proposed currently for Decar would entail flotation to concentrate the awaruite ore, followed by pressure leaching and then solvent extraction. Awaruite, the metal-bearing mineral for Decar, is a nickel-iron alloy composed of nickel and iron with negligible sulphides.

Unlike nickel sulphide concentrates, the Decar concentrate would not require smelting before further processing. In addition, due to its high-grade and consistent feed specifications, the pressure leaching of this concentrate is expected to be less energy-intensive than pressure leaching of laterite ores.

Two batch pressure concentrate tests were conducted in an autoclave with the resulting solution containing low acid and iron. Future testing will focus on downstream processing steps.

The company plans to complete internal trade-off studies to determine the optimal product mix from the project for the stainless steel and battery markets. Additional testing is also planned to refine the pressure leaching scenario and generate nickel products for marketing to potential offtake partners.

Decar hosts current resources of 1.8 billion tonnes in the indicated category grading 0.12% Davis tube recoverable (DTR) nickel for a total of 2.3 million tonnes of contained nickel. Additional inferred resources stand at 391 million tonnes grading 0.12% DTR nickel for 448,000 tonnes of contained metal. Current resources are contained entirely within the Baptiste deposit, one of four awaruite zones identified on the property.

FPX first drilled the Baptiste and Sidney targets in 2010.

For more information, visit

Comments