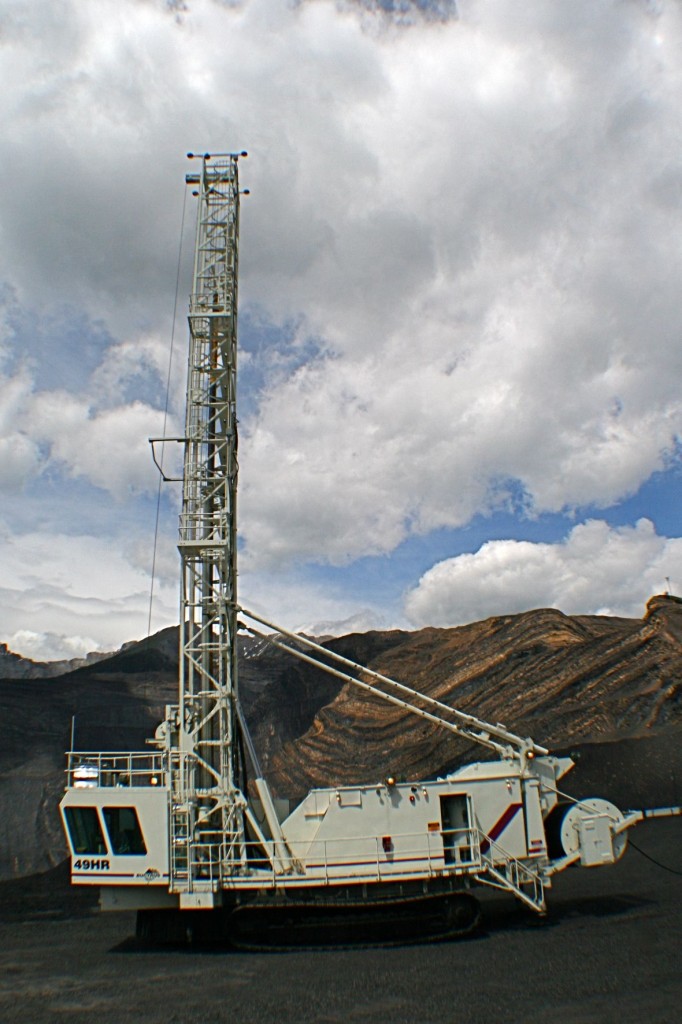

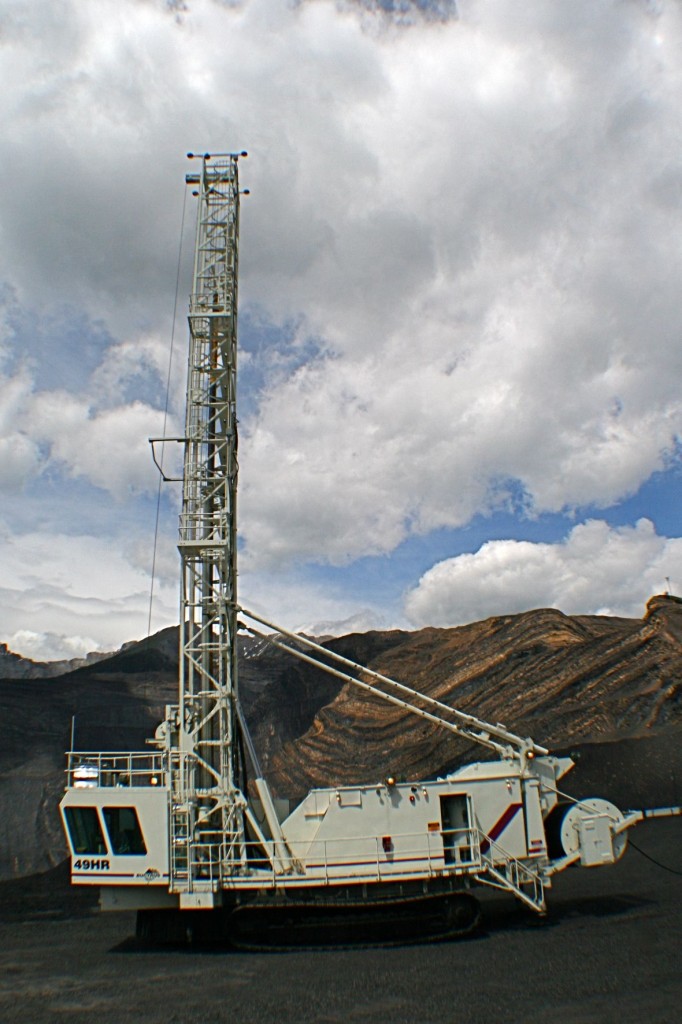

BLASTHOLE DRILLING: Safety, productivity improved on Bucyrus 49R drills

WISCONSIN — Bucyrus International has made what it says are both safety and productivity improvements to its 49 series of rotary blasthole drills. It has introduced a new bit change carousel and a forked pipe wrench for the machines.

The automatic bit change carousel allows up to four drill bit changes to be conducted remotely from the operator’s cab, reducing the typical change-out time of 60 minutes to a mere 10 minutes. That’s an 83% productivity improvement, according to the manufacturer. In addition, the new carousel eliminates seven safety lifting hazards, and avoids the need for drill operators to work under a suspended load.

The forked pipe wrench simplifies pipe unthreading during the drill bit change-out process. First, the forked wrench engages the drill pipe flats. The wrench then rotates, impacting the stop block, causing a break in the pipe thread joint. This new feature reduces the change-out time and the safety risks associated with pipe assembly and disassembly.

These Bucyrus 49 Series improvements are available for both new drills and as a retrofit on existing drills.

Learn more about the latest additions to the ever-expanding stable of Bucyrus rotary drills at www.Bucyrus.com.

Comments