Goldcorp’s Borden project to be first all-electric mine

Goldcorp is building what could be called a stealth mine, if your definition of “stealth” includes the words underground, no mill, small footprint, diesel-free, and environmentally responsible. The first totally electric underground mine in Canada is to be built in the pristine wilderness near Chapleau, Ont.

This is an area long overlooked by the mining community, although

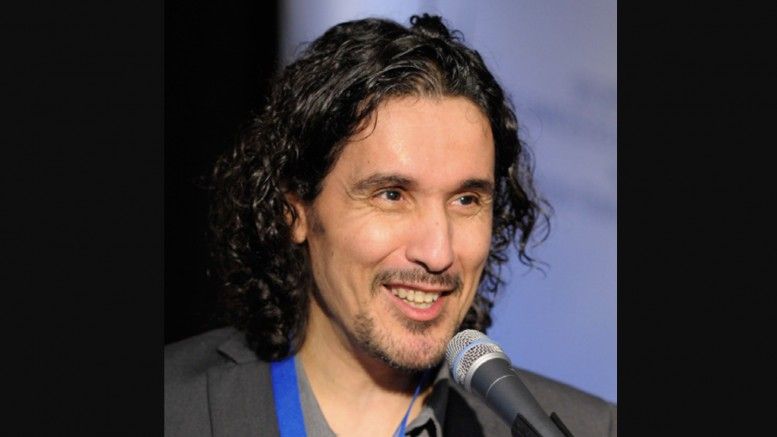

Dave Drake at the controls of the MacLean

975 electric scaler-bolter. (photo: MacLean Engineering)

the forestry industry has been the economic driver in the past. But with forestry in decline, a new mine will be an economic boon to the region. A new, environmentally friendly mine even more so.

“We’ve been welcomed by the Chapleau community,” project manager and general manager of Goldcorp’s Porcupine Gold Mines Marc Lauzier told CMJ. The Borden project will be overseen from the PGM offices in Timmins, Ont., 160 km northeast of the mine site. Having grown up in Chapleau, Lauzier is the perfect choice to head the effort.

The time is right

The time is right for embracing electric vehicles.

Sandvik’s DD442iE jumbo is going to the Borden gold project to drill the access ramp. (photo: Sandvik)

“Batteries have come a long way in the past five years,” said Lauzier. “Older batteries had to be swapped out of the machine and took a long time to charge. Now they can be quick charged on the machine in an hour.”

A healthier workplace is a welcome benefit of going all-electric. No longer will miners be surrounded by a soup of diesel emissions that require large volumes of air to ventilate. There is also a safety factor associated with not storing diesel fuel underground.

Lower capital and sustaining costs are associated with electric equipment. Principally, much less ventilation is needed so the fan installations on the surface will be smaller than conventionally possible. The savings continue as less power is needed to run smaller fans. Smaller fans are less noisy, too.

Goldcorp secured the Borden property as part of its acquisition of Probe Mines in March 2015. Although the project was highly prospective at the time, there was a compliant resource report for the property. Probe put the numbers at 1.6 million oz in the indicated portion and 400,000 oz in the inferred category. Expressed otherwise, there were 9.3 million indicated tonnes averaging 5.39 g/t Au and 3.0 million inferred tonnes at 4.37 g/t (using a 2.5 g/t cut-off).

The plan is to develop a ramp access operation. The Borden project is permitted for underground exploration, and hopefully the permanent permits will be received in a timely fashion and the mine will reach commercial production in mid- 2019. Ore will be trucked to the PGM mill in Timmins for processing.

The company is preparing a prefeasibility study to be completed in the first quarter of next year. The plan is to take a 30,000-tonne bulk sample and provide a platform for underground exploration drilling. The deposit is known to be open at depth and laterally.

Beginning with the adit and ramp, the electric option is the only option.

Sandvik and MacLean Engineering take up the challenge

Two suppliers – Sandvik and MacLean Engineering – have stepped forward with battery powered solutions.

Sandvik is supplying its DD422iE, a two-boom jumbo, for advancing the ramp.

This is the first jumbo that trams on battery power, not diesel. Then while it is plugged in to the electric grid during drilling, the batteries are quick charged at the same time. Or the batteries can be charged when the jumbo is tramming downhill by using energy generated by the braking system. Goldcorp has already purchased one unit that will be delivered early next year when portal and ramp construction begins.

MacLean is supplying two scaler-bolters, scissor lifts, and cassette carriers – all 100% battery powered. They feature the company’s EV battery technology offering high power, high efficiency, and long cycle life battery chemistry. The vehicles are equipped with sophisticated battery management and vehicle monitoring capabilities as well as onboard charging compatible with existing mine infrastructure. The engineering of the integration of the battery power and drive train components was developed in collaboration with MEDATech, a specialized engineering firm.

MacLean’s goal is to offer a battery tramming and operating option on all units across the company’s ground support product line (bolters, shotcrete sprayers and transmixers), its ore flow line (water cannons, secondary reduction drills and mobile rock breakers), and its utility vehicles (boom trucks, scissor lifts, Anfo/emulsion loaders, cassette carriers, personnel carriers, water sprayers, and fuel-lube trucks). The company has set a goal of 2017 to electrify the full line of its equipment.

The challenge going forward, said Lauzier, will be to find battery powered trucks and load-haul-dumpers capable of operating underground for production. Such vehicles have had to be tethered to their power source in the past with a cumbersome electric cord. New battery technology is allowing manufacturers to created battery powered LHDs, for example, as Sandvik is currently doing. There is no doubt that all production equipment can be battery powered in the near future.

The battery powered, environmentally responsible mine is about to become a reality. We applaud the forward thinkers at Goldcorp who are pushing to make it happen. In the end a green Borden mine will only happen when the company, its suppliers and the local community embrace what is possible and put it into action.

Comments